ChevyParts

My Garage

My Account

Cart

OEM Cadillac Intake Manifold

Engine Intake Manifold- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

53 Intake Manifolds found

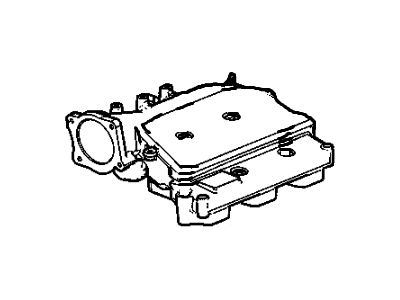

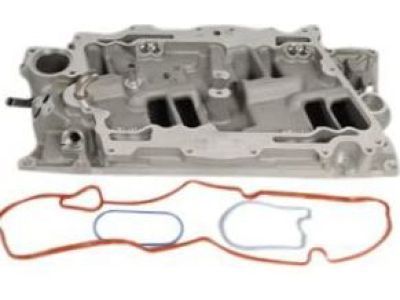

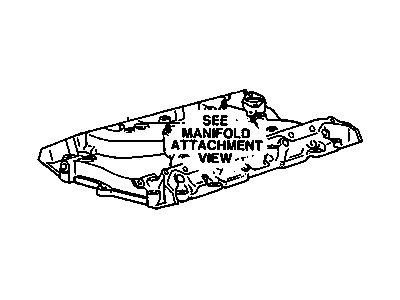

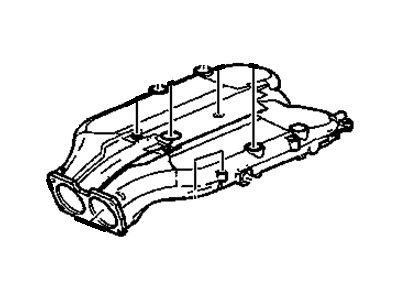

Cadillac Intake Plenum Part Number: 12580250

$48.37 MSRP: $76.80You Save: $28.43 (38%)Product Specifications- Other Name: Plenum-Intake Manifold; Plenum, Engine Fuel Intake Manifold; Duct, Engine Fuel Intake Manifold

- Replaces: 12563719

Cadillac Intake Manifold, Passenger Side Part Number: 12693841

$466.91 MSRP: $741.13You Save: $274.22 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold, Engine Fuel Intake Manifold

- Position: Passenger Side

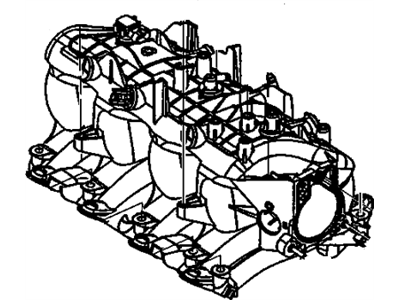

Cadillac Intake Manifold Part Number: 40009057

$126.75 MSRP: $215.75You Save: $89.00 (42%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold, Engine Fuel Intake Manifold

- Replaced by: 40009521

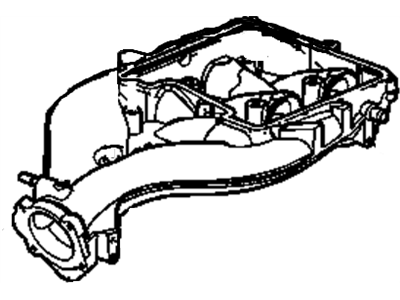

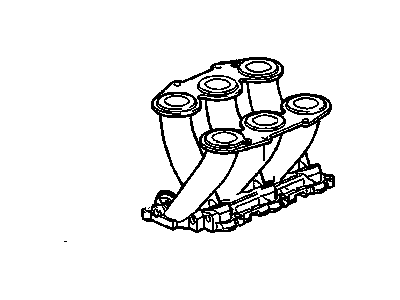

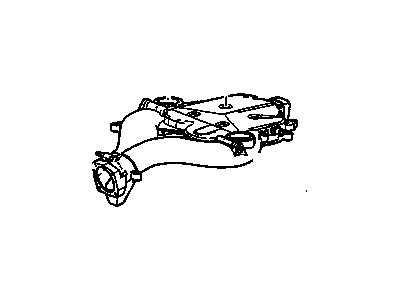

Cadillac Intake Plenum, Upper Part Number: 55561791

$197.61 MSRP: $456.11You Save: $258.50 (57%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Manifold, Upper Intake; Manifold, Engine Fuel Intake Manifold

- Position: Upper

Cadillac Intake Manifold, Driver Side Part Number: 12698230

$462.16 MSRP: $761.13You Save: $298.97 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold, Engine Fuel Intake Manifold

- Position: Driver Side

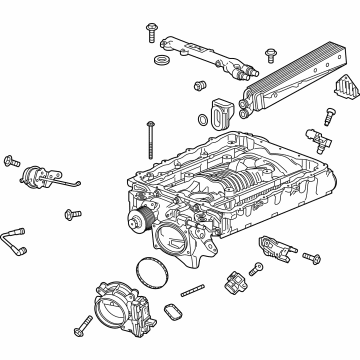

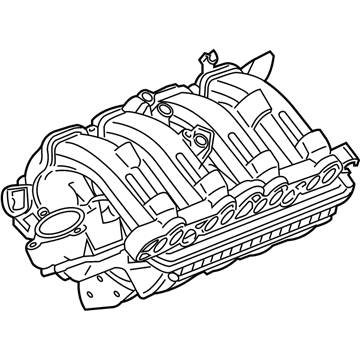

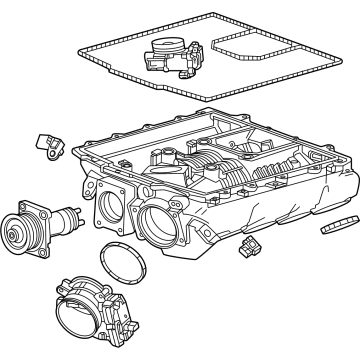

Cadillac Intake Manifold Part Number: 12713777

$3421.56 MSRP: $5626.00You Save: $2204.44 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold, Engine Fuel Intake Manifold; Supercharger

- Replaces: 12703301

Cadillac Intake Manifold Part Number: 12706155

$251.42 MSRP: $399.09You Save: $147.67 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold, Engine Fuel Intake Manifold

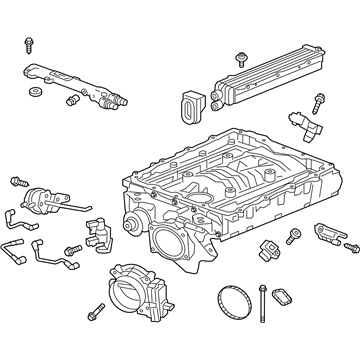

Cadillac Intake Manifold Part Number: 55593173

$409.43 MSRP: $644.20You Save: $234.77 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Manifold, Engine Fuel Intake Manifold

- Replaces: 55568900

Cadillac Intake Manifold Part Number: 12725504

$5935.10 MSRP: $9776.95You Save: $3841.85 (40%)Product Specifications- Other Name: Manifold, Engine Fuel Intake Manifold

- Replaced by: 12740734

Cadillac Intake Manifold Part Number: 12677538

$3254.24 MSRP: $5359.55You Save: $2105.31 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Manifold, Engine Fuel Intake Manifold

- Replaced by: 12701996

Cadillac Intake Manifold Part Number: 17113541

Product Specifications- Other Name: Manifold Kit, Engine Fuel Intake Manifold; Manifold

- Position: Upper

Cadillac Intake Manifold, Lower Part Number: 17113201

Product Specifications- Other Name: Manifold Kit, Lower Intake; Manifold; Manifold Kit, Engine Fuel Intake Manifold

- Position: Lower

Cadillac Manifold Part Number: 17113697

Product Specifications- Other Name: Manifold, Engine Fuel Intake Manifold; Intake Manifold

- Replaces: 17113546

Cadillac Intake Manifold Part Number: 12595765

$267.44 MSRP: $420.63You Save: $153.19 (37%)Product Specifications- Other Name: Manifold, Engine Fuel Intake Manifold

Cadillac Intake Manifold Part Number: 1645790

Product Specifications- Other Name: Manifold; Manifold, Engine Fuel Intake Manifold

Cadillac Intake Manifold Part Number: 12634206

Product Specifications- Other Name: Manifold; Manifold Gasket

Cadillac Intake Manifold Part Number: 90411882

Product Specifications- Other Name: Manifold, Engine Fuel Intake Manifold

- Position: Lower

Cadillac Intake Plenum Part Number: 12597853

Product Specifications- Other Name: Manifold, Engine Fuel Intake Manifold

- Position: Upper

Cadillac Intake Plenum Part Number: 24407506

Product Specifications- Other Name: Manifold, Engine Fuel Intake Manifold

- Position: Upper

Cadillac Intake Plenum Part Number: 12587556

Product Specifications- Other Name: Manifold, Engine Fuel Intake Manifold

- Position: Upper

| Page 1 of 3 |Next >

1-20 of 53 Results

Cadillac Intake Manifold

Choose OEM Intake Manifold, you're making the optimal decision for superior quality and perfect performance. You can feel confident because each component goes through stringent quality checks. Every part is carefully built to comply with Cadillac's factory specifications. You'll enjoy a smooth, worry-free installation that fits just right. At ChevyPartsDeal.com, you'll find it easy to get top-quality OEM Cadillac Intake Manifold. You can shop at highly competitive prices and protect your budget. All our genuine Cadillac parts include a dependable manufacturer's warranty. You'll also appreciate our straightforward return policy and swift delivery services for extra convenience.

Cadillac Intake Manifold Parts and Q&A

- Q: How to replace the intake manifold on Cadillac CTS?A:The first step to replace the Intake Manifold requires removal of both the fuel pipe shield and the air outlet duct. Cut off the brace booster vacuum hose and evaporative emission (EVAP) hose along with positive crankcase ventilation (PCV) hose from the evap solenoid. Start by disconnecting electrical connectors when needed before removing bolts securing the Intake Manifold and removing the component. When replacing the Intake Manifold discard the current gasket. The installation of a new Intake Manifold requires proper assembly at this time. Replace the Intake Manifold Gasket with a new one before installing the manifold by tightening Intake Manifold bolts to a torque of 23nm (17 lb ft). Tighten these bolts following the specified sequence to 23nm (17 lb ft). Complete the installation by connecting electrical connectors followed by evap hose attachment to the evap solenoid and pcv hose connection to the Intake Manifold and Brake Booster Vacuum Hose . You should place back the air outlet duct and the fuel pipe shield for completion.

- Q: How to replace the intake manifold on Cadillac Escalade?A:The Intake Manifold replacement process requires execution of the high voltage service disconnect procedure followed by the disconnection of the battery ground cable. Disassemble the Intake Manifold by removing the air cleaner outlet duct followed by the engine harness retainer nut and retainer from the stud and locator pin. Technicians need to detach electrical connections from the evaporative emission (EVAP) canister purge solenoid , manifold absolute pressure (MAP) sensor , ignition coil harness , left side fuel injectors , throttle actuator , right side fuel injectors , and engine coolant temperature (ECT) sensor . First disconnect the generator control module electrical connector before elevating the engine harness branches into position. Shutdown the quick connect stopper of the evap canister purge tube while also disconnecting the fuel feed line quick connect stopper. The vehicle's positive crankcase ventilation (PCV) hose needs removal before the Intake Manifold bolts (512) are loosened then the Intake Manifold (500) can be taken out. Identify the cylinder head passages for debris prevention while discarding and cleaning all Intake Manifold gaskets (514). Remove the upper Intake Manifold cover nut followed by the upper Intake Manifold cover along with the MAP Sensor retainer and MAP Sensor. Discard the MAP Sensor seal throughout this step. Disconnect the quick connect fitting of the evap tube from the Intake Manifold and dislodge the evap canister purge solenoid retainer to remove the Throttle Body with gasket. Start by removing Fuel Rail bolts before lifting the Fuel Rail evenly to extract the injectors while discarding the Fuel Injector lower o-ring seals. To install new Fuel Injector lower o-ring seals on the injectors apply clean engine oil for lubrication then place the injectors into the Fuel Rail assembly. Use a torque wrench to tighten Fuel Rail bolts to 10 nm (89 lb in). Follow these steps to install a new Throttle Body Gasket and then add the Throttle Body together with its bolts/nuts which must be tightened to 10 nm (89 lb in). After installing the evap tube and purge solenoid you should connect the evap tube quick connect fitting before lubricating the MAP Sensor seal with clean engine oil and putting in the MAP Sensor with its new seal and retainer. First tighten the upper Intake Manifold cover's nut then install new Intake Manifold gaskets (514) all the while removing cylinder head passage covers before placing the Intake Manifold (500). Apply a 5 mm (0.20 in) band of threadlock gm p/n 12345382 to the Intake Manifold bolts (512), install them finger tight, and then tighten them to specifications: design the bolt torque sequence at 5 nm (44 lb in) for the initial run followed by a final torque to 10 nm (89 lb in). After installing the pcv hose you should connect the fuel feed line quick connect fitting and the evap canister purge tube quick connect fitting. Unravel the engine harness branches before connecting the engine harness electrical connector to the ect sensor and securing the engine harness clip on the generator bracket with a bolt torqued to 9 nm (80 lb in). The generator control module electrical connector and engine harness electrical connectors get connected to the right side fuel injectors while a clip gets installed to the ignition coil bracket stud. Tear the cpa retainer seal fitting before you attach the ignition coil harness and the engine harness electrical connectors to left side fuel injectors. The MAP Sensor receives power from the engine wiring harness and the evap canister purge solenoid from the engine harness. Install the engine harness retainer to its stud and locator pin while tightening the retainer nut to a torque of 5 nm (44 lb in) and securing the air cleaner outlet duct. Complete the procedure by connecting the ground cable to the battery and conducting the necessary high voltage service connect.