ChevyParts

My Garage

My Account

Cart

OEM Cadillac Brake Line

Brake Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

179 Brake Lines found

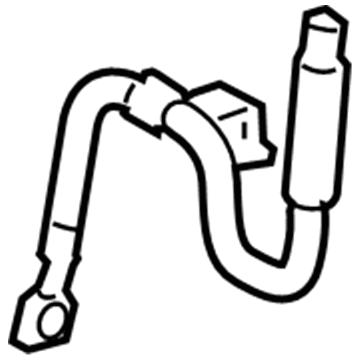

Cadillac Brake Hose, Rear Part Number: 19173041

$13.65 MSRP: $24.38You Save: $10.73 (45%)Product Specifications- Other Name: Hose Assembly, Rear Brake; Hydraulic Hose; Brake Line; Hose; Hose, Hydraulic Brake

- Position: Rear

- Replaces: 09757655, 18031766, 9757655

Cadillac Flex Hose, Front Driver Side Part Number: 22837065

$33.76 MSRP: $63.40You Save: $29.64 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose Assembly-Front Brake; Hydraulic Hose; Brake Hose; Brake Line; Hose, Hydraulic Brake

- Position: Front Driver Side

- Replaces: 25928987, 25875358

Cadillac Flex Hose, Front Passenger Side Part Number: 84999724

$24.04 MSRP: $43.52You Save: $19.48 (45%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hose Assembly-Front Brake; Hydraulic Hose; Brake Hose; Brake Line; Hose, Hydraulic Brake

- Position: Front Passenger Side

Cadillac Flex Hose, Passenger Side Part Number: 20842855

$33.75 MSRP: $61.08You Save: $27.33 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose, Hydraulic Brake; Hydraulic Hose; Brake Hose; Brake Line

- Position: Passenger Side

Cadillac Flex Hose, Front Driver Side Part Number: 84875573

$29.44 MSRP: $53.28You Save: $23.84 (45%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hose Assembly-Front Brake; Hydraulic Hose; Brake Hose; Brake Line; Hose, Hydraulic Brake

- Position: Front Driver Side

- Replaced by: 86529161

Cadillac Flex Hose, Front Passenger Side Part Number: 84650757

$13.16 MSRP: $24.73You Save: $11.57 (47%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hose Assembly-Front Brake; Hydraulic Hose; Brake Hose; Brake Line; Hose, Hydraulic Brake

- Position: Front Passenger Side

Cadillac Flex Hose, Front Passenger Side Part Number: 20842848

$36.22 MSRP: $65.57You Save: $29.35 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose Assembly-Front Brake; Hydraulic Hose; Brake Hose; Brake Line; Hose, Hydraulic Brake

- Position: Front Passenger Side

Cadillac Flex Hose, Front Passenger Side Part Number: 84621217

$14.04 MSRP: $26.36You Save: $12.32 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose Assembly-Front Brake; Hydraulic Hose; Brake Hose; Brake Line; Hose, Hydraulic Brake

- Position: Front Passenger Side

Cadillac Flex Hose, Front Part Number: 19366748

$50.94 MSRP: $95.66You Save: $44.72 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose Assembly, Front Brake; Hydraulic Hose; Brake Hose; Brake Line; Hose, Hydraulic Brake

- Position: Front

- Replaces: 22163944, 25724248

Cadillac Flex Hose, Driver Side Part Number: 84829314

$12.75 MSRP: $23.95You Save: $11.20 (47%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hose, Hydraulic Brake; Hydraulic Hose; Brake Hose; Brake Line

- Position: Driver Side

- Replaced by: 86537633

Cadillac Flex Hose Part Number: 22779672

$23.96 MSRP: $43.35You Save: $19.39 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose, Hydraulic Brake; Hydraulic Hose; Brake Hose; Brake Line

- Position: Rear

- Replaced by: 84025410

Cadillac Flex Hose, Driver Side Part Number: 84560588

$7.27 MSRP: $13.66You Save: $6.39 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose, Hydraulic Brake; Hydraulic Hose; Brake Hose; Brake Line

- Position: Driver Side

- Replaced by: 42876524

- Replaces: 84386359

Cadillac Flex Hose, Passenger Side Part Number: 84829315

$13.41 MSRP: $25.19You Save: $11.78 (47%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hose, Hydraulic Brake; Hydraulic Hose; Brake Hose; Brake Line

- Position: Passenger Side

- Replaced by: 86537634

Cadillac Flex Hose, Driver Side Part Number: 20842853

$29.67 MSRP: $55.75You Save: $26.08 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose, Hydraulic Brake; Hydraulic Hose; Brake Hose; Brake Line

- Position: Driver Side

Cadillac Flex Hose, Front Driver Side Part Number: 84621218

$14.56 MSRP: $26.36You Save: $11.80 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose Assembly-Front Brake; Hydraulic Hose; Brake Hose; Brake Line; Hose, Hydraulic Brake

- Position: Front Driver Side

Cadillac Flex Hose, Front Passenger Side Part Number: 84875572

$29.44 MSRP: $53.28You Save: $23.84 (45%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hose Assembly-Front Brake; Hydraulic Hose; Brake Hose; Brake Line; Hose, Hydraulic Brake

- Position: Front Passenger Side

- Replaced by: 86529160

Cadillac Flex Hose, Front Driver Side Part Number: 85586295

$26.04 MSRP: $48.90You Save: $22.86 (47%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hose Assembly-Front Brake; Brake Hose; Hose, Hydraulic Brake

- Position: Front Driver Side

Cadillac Flex Hose, Passenger Side Part Number: 84988110

$33.35 MSRP: $60.36You Save: $27.01 (45%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Hose, Hydraulic Brake; Hydraulic Hose; Brake Hose; Brake Line

- Position: Passenger Side

Cadillac Flex Hose, Front Driver Side Part Number: 23182555

$18.11 MSRP: $34.00You Save: $15.89 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose Assembly-Front Brake; Hydraulic Hose; Brake Hose; Brake Line; Hose, Hydraulic Brake

- Position: Front Driver Side

- Replaces: 22939274

Cadillac Flex Hose, Driver Side Part Number: 84579662

$13.44 MSRP: $24.34You Save: $10.90 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose, Hydraulic Brake; Hydraulic Hose; Brake Hose; Brake Line

- Position: Driver Side

| Page 1 of 9 |Next >

1-20 of 179 Results

Cadillac Brake Line

Choose OEM Brake Line, you're making the optimal decision for superior quality and perfect performance. You can feel confident because each component goes through stringent quality checks. Every part is carefully built to comply with Cadillac's factory specifications. You'll enjoy a smooth, worry-free installation that fits just right. At ChevyPartsDeal.com, you'll find it easy to get top-quality OEM Cadillac Brake Line. You can shop at highly competitive prices and protect your budget. All our genuine Cadillac parts include a dependable manufacturer's warranty. You'll also appreciate our straightforward return policy and swift delivery services for extra convenience.

Cadillac Brake Line Parts and Q&A

- Q: How to replace the intermediate brake line assembly on Cadillac CTS?A:Vehicle lifting starts the replacement process of intermediate brake hose assembly. First clean all dirt and foreign debris from brake hose and brake pipe fittings before removing the right rear tire and wheel assembly. You need to detach the crossover brake pipe fitting from the intermediate brake hose assembly before capping the brake pipe fitting to stop brake fluid loss and contamination. Before disconnecting any fittings first remove the brake hose retainer from the rear frame bracket by using a flat bladed tool. To detach the brake caliper from its hose, first separate the bolt fitting on the brake caliper and remove the brake hose then seal the inlet port to avoid fluid leakages. Tap the brake hose fitting bolt threaded end against a shop towel placed on a solid surface to eliminate the gaskets while discarding any stuck copper gaskets from either the caliper or hose end. The intermediate brake hose assembly mounting nuts must be removed from the studs so the installers can extract the intermediate brake hose assembly from the vehicle. Make sure to install the brake hose without creating any kinks or twisting in the line. Mount the intermediate brake hose assembly on its studs then fasten it with mounting nuts tightened to 10 n.m (89 lb in). The intermediate brake hose assembly will be attached to both brake pipe fittings ahead of placing new copper brake hose gaskets in the brake caliper inlet port. The brake hose assembly requires installation of the new copper brake hose gaskets along with the fitting bolt to the brake hose and final placement of the bolt onto the brake caliper with a torque setting of 49 n.m (36 lb ft). The crossover brake pipe fitting and intermediate brake hose assembly need to join with proper tightening to 18 n.m (13 lb ft). Complete the brake bleeding procedure then put the wheel and tire back into place.

- Q: What are the steps and precautions for replacing brake lines on Cadillac Escalade?A:During the replacement of brake pipes, always use double-walled steel brake pipe in order to obviate brake system failure, when routing pipes correctly, and retaining the pipes, using the right fasteners on their correct places in order to mitigate the criticism that may bring about the damage which could cause personal injury. Parallel brake pipes should have a 6mm (1/4 in) stick out. Start with a braking pipe-detach the brake pipe with the help of braking pipe fittings, thereafter give brakes pipe fasteners a break from the vehicle & remove brake pipe. Next, bend the new brake pipe for a good fitting at the vehicle and fix it in a vehicle with a 25 mm (1 in) clearance from any moving or vibrating part of the vehicle. While securing the brake pipe fasteners, hook up the brake pipe connectors to the brake pressure modulator valve (BPMV) or wheel jounce hoses to the same torque of 25 N.m (18 lb ft) and to the master cylinder, also to 25 N.m (18 lb ft). Lastly, bleed the hydraulic brake system with the Antilock Brake System Automated Bleed Procedure.