ChevyParts

My Garage

My Account

Cart

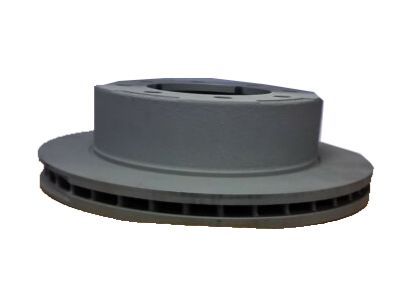

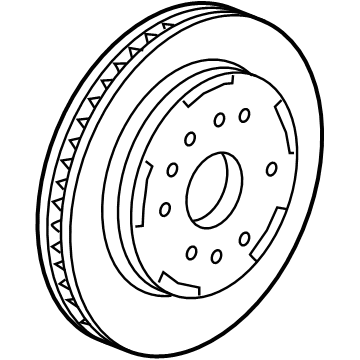

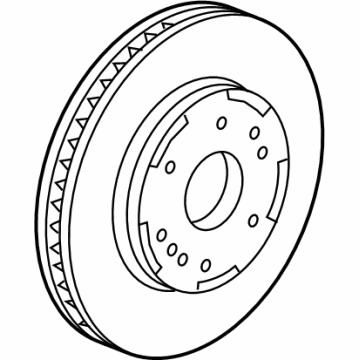

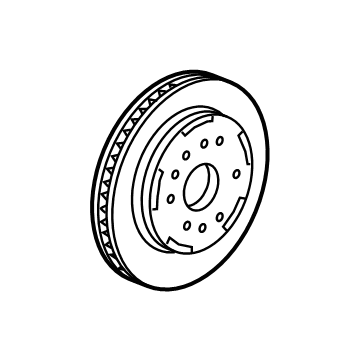

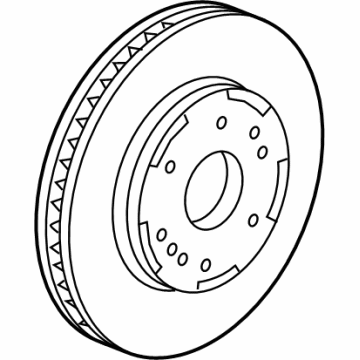

OEM GMC Sierra 1500 Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

15 Brake Discs found

GMC Sierra 1500 Rotor, Rear Part Number: 23195438

$132.84 MSRP: $256.20You Save: $123.36 (49%)

GMC Sierra 1500 Rotor, Front Part Number: 23144340

$140.08 MSRP: $274.25You Save: $134.17 (49%)

GMC Sierra 1500 Brake Rotor Part Number: 25757802

$113.95 MSRP: $219.81You Save: $105.86 (49%)Ships in 1-2 Business Days

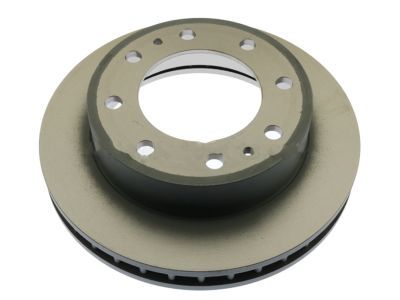

GMC Sierra 1500 Rotor Part Number: 15712803

$170.40 MSRP: $325.78You Save: $155.38 (48%)Ships in 1-2 Business Days

GMC Sierra 1500 Rotor Part Number: 15712801

$96.36 MSRP: $180.93You Save: $84.57 (47%)

GMC Sierra 1500 Rotor, Front Part Number: 22950036

$121.44 MSRP: $235.71You Save: $114.27 (49%)Ships in 1-3 Business Days

GMC Sierra 1500 Rotor, Front Part Number: 19210603

$94.27 MSRP: $182.96You Save: $88.69 (49%)Ships in 1-2 Business Days

GMC Sierra 1500 Rotor, Front Part Number: 15942195

$154.61 MSRP: $302.70You Save: $148.09 (49%)Ships in 1-2 Business DaysGMC Sierra 1500 Rotor, Rear Part Number: 13552815

$116.70 MSRP: $225.08You Save: $108.38 (49%)GMC Sierra 1500 Rotor Part Number: 13553983

$137.88 MSRP: $252.98You Save: $115.10 (46%)GMC Sierra 1500 Rotor, Rear Part Number: 87842411

$81.22 MSRP: $157.68You Save: $76.46 (49%)Ships in 1-2 Business DaysGMC Sierra 1500 Rotor Part Number: 84879622

$243.85 MSRP: $464.25You Save: $220.40 (48%)Ships in 1-3 Business Days

GMC Sierra 1500 Rotor, Rear Part Number: 22968231

GMC Sierra 1500 Rotor Part Number: 19211496

GMC Sierra 1500 Rotor Part Number: 26088273

GMC Sierra 1500 Brake Disc

Want to cut long-term maintenance and repair costs? Choose OEM Brake Disc. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine GMC Sierra 1500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM GMC Sierra 1500 Brake Disc includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

GMC Sierra 1500 Brake Disc Parts and Q&A

- Q: How Should You Properly Refinish a Brake Disc on GMC Sierra 1500?A:Brake Disc service and repair need a disc resurfacing kit (J 41013) and wheel hub resurfacing kit (J 42450-A). The brake system team does not need to refinish disc brake discs during normal vehicle maintenance. Technicians should avoid refurbishing new discs for things such as brake noise, uneven or premature pad wear, surface corrosion, minor scoring, or to fix high lateral runout (LRO). Workers must inspect the disc thickness first to make sure refinishing does not decrease the minimum approved thickness. When thickness issues, significant corrosion, fractures, blue stains, or deep scoring show up the parts call for a refinishing process. Start by removing all dirt and rust from the hub/axle flange and Brake Disc surfaces using the wheel hub resurfacing kit part j 42450-a and the disc resurfacing kit part j 41013. Make sure the brake mating surfaces are free from particles before doing the disc installation onto the brake lathe. Please let the lathe run while you introduce cutting tools to touch both disc friction areas and check the mark to make sure the parts attach correctly. Install the disc onto the machine like indicated by the lathe manufacturer. Sand using defined methods before measuring the disc thickness at regular intervals. Replace the disc and start new rebuilding work once thickness falls below specified limits. Replacing the disc is necessary if its thickness is above the specified limit. Set the device to its recommended speed setting and sand the disc surfaces with either 120 grit aluminum oxide sandpaper on the non-directional tool or 150 grit sandpaper on the sanding block. Wipe friction surfaces with denatured alcohol or an approved brake cleaner. After taking the disc out of the lathe use measurement tools to check if the entire braking system performs properly for specific tolerances.

- Q: How to replace the front brake disc on a 1500 Series on GMC Sierra 1500?A:The replacement of front brake rotors on 1500 series vehicles requires owning both rotor resurfacing kit (J41013) and wheel hub resurfacing kit (J42450-A). First check the brake master cylinder reservoir fluid level while making sure the mark is between the maximum and minimum indicators. Start by disassembling the wheel and tire then note how the rotor fits with the hub. The use of two large c-clamps allows for piston compression followed by remaining at position while removing Brake Caliper Bracket bolts and caliper assembly without braking hose attachment. Separated brake hub or rotor components can be unlocked using a deadblow hammer. Brake rotor retaining push nuts and brake rotor screw need removal before striking the assembly. You must use the wheel hub resurfacing kit (J42450-A) together with the rotor resurfacing kit (J41013) to clean all rust and contaminates from both the hub/axle flange and brake rotor mating surfaces. Inspection of hub flange surfaces should identify any present debris and reveal nicks and marks. Apply the rotor to its proper position before fastening it with the brake rotor screw which needs tightening to 12 nm (106 inch lbs.). The lateral runout measurement should be conducted on the assembled rotor then adjustments made to restore it within specification limits. Reinstall the caliper with caliper bracket while cleaning the caliper bracket bolts first before applying threadlocker gm p/n 12345493 (Canadian P/N 10953488) and torquing bolts to 180 nm (133 ft. Lbs.). The last step involves reattaching the tire alongside the wheel assembly followed by lowering the vehicle before applying the brake pedal carefully to reach a firm feel while adding new brake fluid to the master cylinder if needed.