ChevyParts

My Garage

My Account

Cart

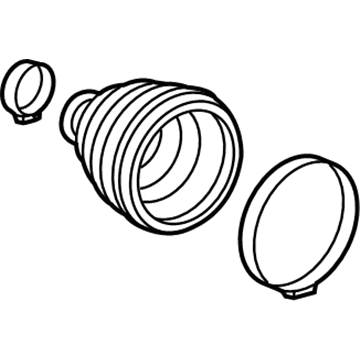

OEM Cadillac CTS CV Boot

Axle Boot- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

10 CV Boots found

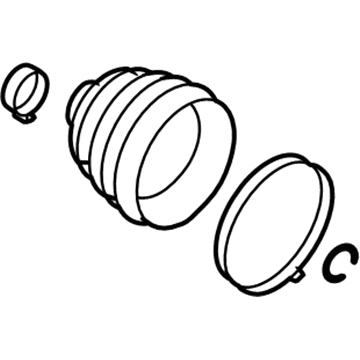

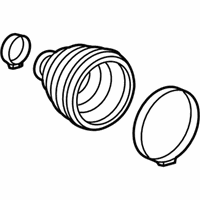

Cadillac CTS Outer CV Joint Boot Part Number: 88957226

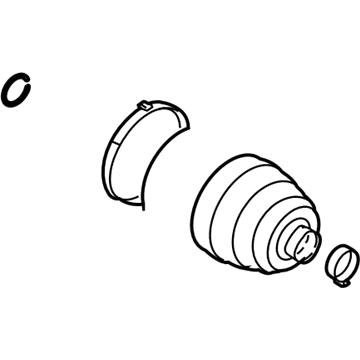

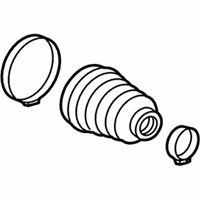

$57.16 MSRP: $97.30You Save: $40.14 (42%)Cadillac CTS Inner CV Joint Boot Part Number: 88957225

$63.99 MSRP: $95.95You Save: $31.96 (34%)Ships in 1-2 Business DaysCadillac CTS Outer Boot, Rear Part Number: 19206244

$189.81 MSRP: $301.35You Save: $111.54 (38%)Cadillac CTS Inner Boot, Rear Part Number: 19148848

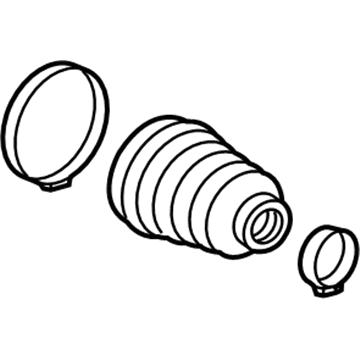

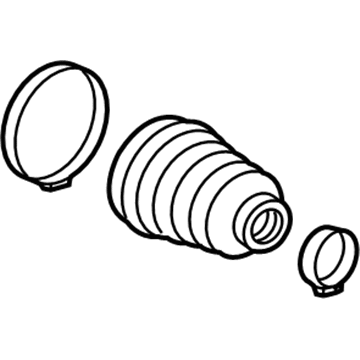

Cadillac CTS Boot Kit Part Number: 89047823

Cadillac CTS Outer Boot Part Number: 88957230

Cadillac CTS Boot Kit Part Number: 88952506

Cadillac CTS Boot Kit, Inner Part Number: 26091453

Cadillac CTS Boot Kit, Rear Part Number: 26091452

Cadillac CTS Outer Boot, Rear Part Number: 25782407

$52.75 MSRP: $82.64You Save: $29.89 (37%)

Cadillac CTS CV Boot

Want to cut long-term maintenance and repair costs? Choose OEM CV Boot. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Cadillac CTS parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Cadillac CTS CV Boot includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

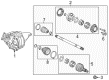

The CV Boot in Cadillac CTS vehicles is very vital because it helps to protect the Constant Velocity (CV) Joints that is used in the transference of power from the transaxle to the wheels. This soft enfnet or open ended rubber or plastic part retains the correct amount of lubricant in the joint and is capable of absolute exclusion of any dirt in the joint for improved functionality. Certain types of CV joints employed in Cadillac CTS models are available such as Rzeppa kind at the outer end and tripod or double offset kind at the inner end. The outer joints are for those which experience larger movements in angle and the inboard joints for those that experience changes in shaft length due to suspension operation. It is usually recommended to check the CV Boot frequently because any kind of damage to the CV Boot such as crack or tearing could lead to bad state of the CV joint hence affecting the overall performance of the vehicle.

Cadillac CTS CV Boot Parts and Q&A

- Q: How to replace the front outer CV Boot and CV Joint on Cadillac CTS?A:The replacement process for the front wheel drive shaft outer joint boot starts by extracting the wheel drive shaft from the vehicle's system. First secure the wheel drive shaft horizontally in the bench vise with a shop towel wrapping around the Axle Shaft. Replace all retaining clamps with new ones during installation. Current retaining clamps require replacement with brand new components. Cut open each retaining clamp from the outer boot with a side cutter before removing the boot from the cv joint housing to clean grease off the inner race cage and balls. To extract the outer cv joint from the Axle Shaft perform these tasks. First position the outer joint housing horizontally then place a wood block between the seal and joint. After that strike the cv joint from the wheel drive shaft with a hammer. A combination of brass drift and hammer should be used for extra force when necessary. Follow these steps for Axle Shaft retaining ring removal and boot extraction from the Axle Shaft. Place the vertical joint outer race splined shaft into a bench vise and use a brass drift and hammer to gently hit the inner cage of the cv joint while removing balls to clean all debris from inner race, outer race, cage, balls and exposed Axle Shaft end with clean solvent followed by complete air drying. Any defective interior parts will require replacement of the wheel drive shaft. To build the assembly start with the cage positioned upright with larger radius corners facing upward and then place the inner race inside followed by setting the groove of the inner race up. Place the joint outer race splined shaft vertically in a bench vise while surrounding it with a shop towel. Keep the inner race ball tracks properly lined up with cage windows. Place the assembly at ninety degrees between the outer race while positioning the lower side of the inner race ring groove because of its design. Action and compression of the cage allow access to ball tracks while ball insertion allows for tracking checks with the inner race ball track. Prior to pulling the outer joint from the vise you should apply approximately 60% of the service kit grease to the outer joint. Then place a shop towel around the Axle Shaft and set the wheel drive shaft horizontally in a bench vise before installation. Affix a new small seal retaining clamp to the Axle Shaft before adding the seal and its new retaining ring. Drive the outer joint onto the shaft with a wood block and hammer until it becomes fully seated. Meanwhile use a different hand to squeeze the Axle Shaft retaining ring against the splines of the inner race until both components are engaged. Grease the seal completely before positioning the small seal retaining clamp into the boot groove. Verify the boot maintains its proper shape while having no damage present. Use j 42572 to crimp the small seal retaining clamp, creating a 1 mm (0.039 in) gap for inspection before placing the large seal retaining clamp onto the seal and joint outer race. Check the boot's shape and condition. Combine j 42572 to crimp the large seal retaining clamp. Match the crimped area to a 1 mm separation while keeping the clamp engaged for 2 seconds minimum. Next, verify the outer joint runs smoothly as you rotate the wheel drive shaft.

- Q: How to replace the Rear Wheel Drive Shaft Outer CV Boot on Cadillac CTS?A:To replacements the rear wheel drive shaft outer joint boot, you need to, first, remove the wheel drive shaft and wrap one in shop towels around the Axle Shaft and lay the wheel drive shaft horizontally in the bench vise. Do not reuse the retaining clamps. Instead, increase the cutting angle (side cutter) and eliminate them, too. Then, carefully remove the boot from CV Joint housing, scrub off the grease from CV Joint's inner race, cage and balls. To dishevel the outer CV Joint from the axle train, it is necessary to hold the outer joint housing up horizontally and insert a wood block between a seal and the joint, then using a hammer to knock out the CV Joint from the wheel drive shaft. In case of necessity, a brass drift could be used to help. Discard the Axle Shaft retaining ring and pull off the boot from the Axle Shaft. After pulling out the wheel drive shaft from the vise, wrap a shop towel around the joint outer race splined, put the outer race vertically in a bench vise. Tap gently on the wheel drive shaft joints inner cage with a brass drift and hammer till the 1st ball is removed, then sequentially remove all the balls. Clean inner and outer race, cage and balls by manually soaking in solvent and air drying. Change the wheel drive shaft in case there are some inner parts that are faulty. Prepare cage by placing the larger radius points up, put in the inner race to the cage and make sure its grooved surface is up. Note the alignment of interior raceball tracks with the cave windows, loop a shop fireworks around the confederation outlying race splined shaft, and post the outer array vertically into a court vise. Mount the cage and inner race at 90 degree to the outer race facing down in the ring groove. Mount the balls one at a time, and make sure that the gap between the ball and the inner race track is not present. Introduce about 60 percent of the grease from the service kit into the outer joint, the contents evenly distributed in ball tracks, balls, cage, and inner race and take the outer joint out of the vise. Take a shop towel or an old rag and wrap it around the Axle Shaft and then place the wheel drive shaft in a horizontal position in a bench vice, while install new small seal retaining clamp onto the Axle Shaft, then install the seal and a new retaining ring. Push the inner race splines onto the Axle Shaft splines, compress the Axle Shaft retaining ring, and drive the outer joint onto the Axle Shaft, slapping it on with a wood block and hammer until seated. Add the rest of the grease into the seal, insert the small seal retaining clamp into the boot groove, and verify that the boot is properly shaped and unchipped. Crimp the small seal retaining clamp in j 42572 until 1 mm gap, then secure the large seal retaining clamp onto the seal and crimp just as well. Finally, rotate the wheel drive shaft a couple of times and inspect the outer joint for smooth operation before re-installing the wheel drive shaft.