ChevyParts

My Garage

My Account

Cart

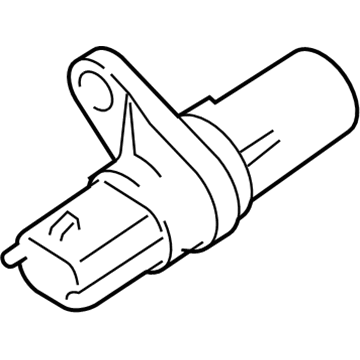

OEM Cadillac CTS Crankshaft Position Sensor

Engine Crankshaft Position Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Crankshaft Position Sensors found

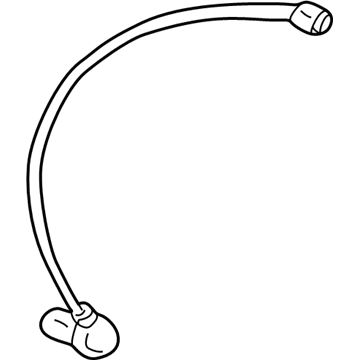

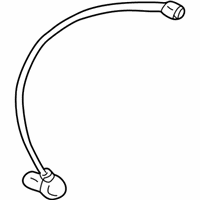

Cadillac CTS Crankshaft Position Sensor Part Number: 12703627

$60.13 MSRP: $107.38You Save: $47.25 (44%)

Cadillac CTS Crankshaft Position Sensor Part Number: 12674702

$44.84 MSRP: $91.06You Save: $46.22 (51%)Ships in 1-2 Business Days

Cadillac CTS Crankshaft Position Sensor Part Number: 12669636

$28.91 MSRP: $54.30You Save: $25.39 (47%)Ships in 1-3 Business Days

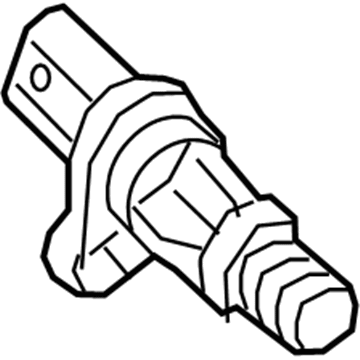

Cadillac CTS Crankshaft Position Sensor Part Number: 12646781

$14.45 MSRP: $27.14You Save: $12.69 (47%)Ships in 1-2 Business Days

Cadillac CTS Crankshaft Position Sensor Part Number: 12615626

$17.35 MSRP: $32.60You Save: $15.25 (47%)Ships in 1 Business Day

Cadillac CTS Crankshaft Position Sensor Part Number: 12613030

$36.50 MSRP: $68.55You Save: $32.05 (47%)Ships in 1 Business Day

Cadillac CTS Crankshaft Position Sensor Part Number: 12582652

$138.93 MSRP: $260.90You Save: $121.97 (47%)Ships in 1-2 Business Days

Cadillac CTS Crankshaft Position Sensor Part Number: 12560228

$66.20 MSRP: $119.82You Save: $53.62 (45%)Cadillac CTS Crankshaft Position Sensor Part Number: 90494182

Cadillac CTS Crankshaft Position Sensor

Want to cut long-term maintenance and repair costs? Choose OEM Crankshaft Position Sensor. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Cadillac CTS parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Cadillac CTS Crankshaft Position Sensor includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

The Crankshaft Position Sensor on Cadillac cts is an important digital device to monitor the crank shaft position and its revolutions. From this information, it sends to the power train control module, thus enabling it to control on the fuel injection as well as the ignition time thus ensuring improved engine performance. The Crankshaft Position Sensor is one of the important components which can hinder the Cadillac CTS from starting or may cause problems during the drive. Thus, the Cadillac CTS model has equipped different types of the Crankshaft Position Sensors, such as inductive, Hall Effect, magnetoresistive, and optical ones. Inductive sensors are non-energized while Hall Effect and magnetoresistive sensors are capable of sensing dc magnetic fields. Optical sensors are very useful for edge detection but is is possible for them to be fouled. The kind of sensors used can affect the sensors dependability and performance according to the circumstance of use back in drive.

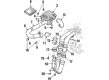

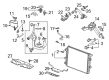

Cadillac CTS Crankshaft Position Sensor Parts and Q&A

- Q: How to replace the Crankshaft Position Sensor on Cadillac CTS?A:Lift and support the vehicle first to change the crankshaft position (CKP) sensor. Unscrew the bolt holding the ckp sensor to the engine block, and remove the ckp sensor and o-ring seal. This requires lowering the vehicle, if it is necessary, to lift all components and pull out components which will be based on the rpo code with the requirement to gain access to the ckp sensor pigtail which may be the requirement of the Wiper Motor module in the case of lhd or in the case of rhd; the removal of the left air inlet grill panels and the removal of the front air inlet panel assembly. After that, you should disconnect the wiring harness connector from the ckp sensor pigtail; remove the pigtail off the retainer. Cut away the tie strap that holds the pigtail to the oil cooler pipes and connect a piece of scrap wire approximately 91 cm (36 in) to the pigtail for later use as a pull wire. Take the ckp sensor pigtail off while watching where it runs and remove the sensor from it out of the pull wire. For the installation the ckp sensor pigtail to the lower end of the pull wire, and use it to guide the pigtail back in place. Unplug the pull wire from pigtail; connect ckp sensor pigtail to retainer and the wiring harness connector. Lift and support the vehicle a second time, clean the mating surfaces of ckp sensor, as well as the engine block, and install the ckp sensor with a new o-rings seal. Mount the bolt fastening the ckp sensor to the engine block and tighten it to 8 n.m (71 lb in). Check the routing of the harness so that it does not touch the Exhaust Manifold, and then lower the vehicle. Depress the ckp sensor pigtail to the oil cooler pipes with a tie strap and install components dependent on the rpo code, tightening the front air inlet panel assembly bolts to the 6 n.m (53 lb in).

- Q: How to service and repair the Crankshaft Position Sensor on Cadillac CTS?A:To service and repair the Crankshaft Position Sensor, do the following: raise and support the vehicle first. And after removing the bolt supporting the crankshaft position (CKP), sensor on the engine block, then pull the ckp sensor and the o-ring seal. Lower down the vehicle, and remove the components according to the rpo code in order to reach the ckp sensor pigtail which may include the Wiper Motor module (LHD), the left air inlet grill panel (RHD), the front air inlet panel assembly bolts and the front air inlet panel assembly. Remove the wiring harness connector out of ckp sensor pigtail and remove pigtail from the retainer. Cut the tie strap connecting pigtail to the oil cooler pipes, - attach a scrap wire of approximately 91 cm (36 in.) to the ckp sensor pigtail for later use as a pull wire. Take the pigtail ckp sensor off and inspect the routing while pulling it down on the routing. Remove the sensor from the pull wire. For installation, tie the ckp sensor pigtail to the bottom of the pull wire and use it to guide to reformulate lead the pigtail in position. After detaching the pull wire from the sensor pigtail, link the ckp sensor pigtail to the retainer and the wiring harness connector. Raise and support the vehicle once more, clean the mating surfaces of ckp sensor and the engine block and install ckp sensor with new o-ring seal into the engine block. Fix the sensor with the bolt and tighten it up to 8 n.m (71 lb in). Check the harness for correct application and be sure that it does not touch the exhaust manifold and then drop the vehicle. Secure the ckp sensor pigtail to the oil cooler pipes with a tie strap and replace the components according to the rpo code - the Wiper Motor module if lhd, the front air inlet panel assembly, tighten the front air inlet panel assembly bolts at 6 n.m (53 lb. In.), and left air inlet grill panel if rhd.