ChevyParts

My Garage

My Account

Cart

OEM 2009 GMC Sierra 1500 Pinion Bearing

Transmission Pinion Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Pinion Bearings found

2009 GMC Sierra 1500 Side Bearings Part Number: 11505123

$51.58 MSRP: $152.62You Save: $101.04 (67%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing, Differential Side Gear; Differential Pinion Bearing; Differential Bearing; Bearing

- Item Weight: 1.60 Pounds

- Item Dimensions: 4.9 x 1.4 x 5.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 11505123

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2009 GMC Sierra 1500 Wheel Bearing Part Number: 9436881

$57.71 MSRP: $145.36You Save: $87.65 (61%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Bearing, Differential; Differential Pinion Bearing; Differential Bearing; Axle Bearings; Shaft; Inner; Side; Differential Gear; Front Wheel; Rear Wheel; Nut.

- Item Weight: 1.70 Pounds

- Item Dimensions: 5.1 x 1.5 x 5.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 9436881

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2009 GMC Sierra 1500 Side Bearings Part Number: 25824250

$65.71 MSRP: $128.64You Save: $62.93 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing, Differential Side Gear; Differential Pinion Bearing; Differential Bearing

- Replaces: 09418390, 9418390

- Item Weight: 1.20 Pounds

- Item Dimensions: 4.3 x 4.3 x 2.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 25824250

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2009 GMC Sierra 1500 Pinion Bearings Part Number: 23243839

$56.88 MSRP: $110.40You Save: $53.52 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing, Differential Pinion; Differential Pinion Bearing; Rear Pinion Bearing; Front/Inner/Outer Pinion; Diff/Drive Axle; Pinion/Clutch/Rear Wheel

- Position: Front

- Replaces: 09418357, 26053758, 9418357, 15286375, 20997052, 22786621, 9418356, 09418356, 12479221

- Item Weight: 1.30 Pounds

- Item Dimensions: 4.2 x 4.2 x 2.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 23243839

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2009 GMC Sierra 1500 Pinion Bearings Part Number: 9413427

$56.84 MSRP: $109.76You Save: $52.92 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing, Differential Drive Pinion Gear Outer; Differential Pinion Bearing; Rear, Front, Outer Pinion Bearings; Differential Drive, Steering Knuckle King, Pinion Shaft, Front Axle Bearings.

- Item Weight: 1.20 Pounds

- Item Dimensions: 3.1 x 3.2 x 3.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 9413427

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2009 GMC Sierra 1500 Pinion Seal, Outer Part Number: 25824252

$47.14 MSRP: $92.28You Save: $45.14 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing, Differential Drive Pinion Gear Outer; Differential Pinion Bearing; Pinion Bearings; Side Bearings; Bearing; Bearing, Pinion Shaft Front

- Position: Outer

- Item Weight: 1.30 Pounds

- Item Dimensions: 4.2 x 4.2 x 2.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 25824252

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2009 GMC Sierra 1500 Pinion Bearings Part Number: 9414917

$70.11 MSRP: $133.08You Save: $62.97 (48%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing, Differential Drive Pinion Gear Inner; Differential Pinion Bearing; Differential Bearing; Rear Pinion Bearing; Drive Pinion Rear; Axle Pinion Shaft; Ring And Pinion; Pinion Shaft Front.

- Position: Inner

- Item Weight: 2.40 Pounds

- Item Dimensions: 4.4 x 5.1 x 2.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 9414917

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2009 GMC Sierra 1500 Pinion Bearings Part Number: 9417781

$43.86 MSRP: $103.28You Save: $59.42 (58%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing, Front Differential Drive Pinion Gear Outer; Differential Pinion Bearing; Rear, Front, Outer Pinion Bearing; Differential Drive Pinion Front, Drive Pinion, Pinion Shaft Front, Front Axle

- Position: Front Outer

- Item Weight: 1.40 Pounds

- Item Dimensions: 3.4 x 3.6 x 1.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 9417781

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2009 GMC Sierra 1500 Pinion Bearing

With a comprehensive array of OEM 2009 GMC Sierra 1500 Pinion Bearing, from fuel pumps to door handles, our website is a one-stop-shop for your needs. All our genuine 2009 GMC Sierra 1500 Pinion Bearing are backed by the manufacturer's warranty and are offered at competitive prices in the market. Rest assured, you can shop with complete confidence.

2009 GMC Sierra 1500 Pinion Bearing Parts and Q&A

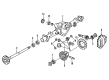

- Q: How to replace the drive pinion bearings on 8.6, 9.5, or 11.5 inch axles on 2009 GMC Sierra 1500?A: The first step to replace drive pinion bearings in 8.6 9.5 or 11.5 inch axles is to elevate and stabilize the vehicle. First remove the Differential assembly before taking out the drive pinion from the axle. To disassemble the drive pinion from 8.6 inch axles you should employ the dt 47688 (Pinion Bearing Remover) paired with a press tool. The j 22912 (Bearing Remover) together with a press should be used to remove the Differential Pinion Bearing from vehicles that have the 9.5 ld inch axle. Separate the shim while using a hammer along with a brass drift to extract the outer and inner Pinion Bearing cups from the housing of the axle. Use j 8611-01 (Pinion Bearing Cup Installer) for the 8.6 inch axle in conjunction with j 7818 (Inner Bearing Race Installer) for the 9.5/9.5ld inch axle to mount the outer Pinion Bearing cup while the j 45870 (Inner Pinion Bearing Race Installer) for the 8.6 inch axle must be combined with j 22306 (Bearing Race Installer) for the 9.5/9.5ld inch axle to assemble the inner Pinion Bearing cup. Select the correct drive pinion shim along with placement of this shim onto the Differential pinion gear shoulder. The bearing needs pressing onto the pinion shim until the cone seats before you can install it with a j 22828 (Input Shaft Gear Installer) or a j 36614 (Inner Pinion Bearing Installer). A new collapsible spacer should be installed before the pinion bearings receive an application of factory-specified axle lubricant. The installation of the axle housing outer Pinion Bearing initiates before setting the Differential pinion gear. First replace the old pinion nut with a new one before installing the new Differential pinion oil seal together with the flange/yoke along with the new nut and washer. The rotating torque measurement of the pinion should be in the range of 1.0-2.3 nm (10-20 lb in) for used bearings or 1.7-3.4 nm (15-30 lb in) for new bearings. The procedure calls for adding small increments to pinion nut torque until you meet the specified measurement range. Test the pinions' rotation several times before a second evaluation of the rotating torque and re-correction if needed. Install the Differential assembly after lubricating the axle with proper fluid before completing the process by lowering the vehicle.