ChevyParts

My Garage

My Account

Cart

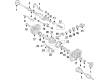

OEM 2004 Chevrolet SSR Pinion Bearing

Transmission Pinion Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Pinion Bearings found

2004 Chevrolet SSR Side Bearings Part Number: 25824250

$65.71 MSRP: $128.64You Save: $62.93 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing, Differential Side Gear; Differential Pinion Bearing; Differential Bearing

- Replaces: 09418390, 9418390

- Item Weight: 1.20 Pounds

- Item Dimensions: 4.3 x 4.3 x 2.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 25824250

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2004 Chevrolet SSR Pinion Bearings Part Number: 23243839

$56.88 MSRP: $110.40You Save: $53.52 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing, Differential Pinion; Differential Pinion Bearing; Rear Pinion Bearing; Front/Inner/Outer Pinion; Diff/Drive Axle; Pinion/Clutch/Rear Wheel

- Position: Front

- Replaces: 09418357, 26053758, 9418357, 15286375, 20997052, 22786621, 9418356, 09418356, 12479221

- Item Weight: 1.30 Pounds

- Item Dimensions: 4.2 x 4.2 x 2.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 23243839

- Warranty: This genuine part is guaranteed by GM's factory warranty.

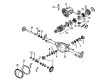

2004 Chevrolet SSR Pinion Bearings Part Number: 9413427

$56.84 MSRP: $109.76You Save: $52.92 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing, Differential Drive Pinion Gear Outer; Differential Pinion Bearing; Rear, Front, Outer Pinion Bearings; Differential Drive, Steering Knuckle King, Pinion Shaft, Front Axle Bearings.

- Item Weight: 1.20 Pounds

- Item Dimensions: 3.1 x 3.2 x 3.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 9413427

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2004 Chevrolet SSR Pinion Bearing

With a comprehensive array of OEM 2004 Chevrolet SSR Pinion Bearing, from fuel pumps to door handles, our website is a one-stop-shop for your needs. All our genuine 2004 Chevrolet SSR Pinion Bearing are backed by the manufacturer's warranty and are offered at competitive prices in the market. Rest assured, you can shop with complete confidence.

2004 Chevrolet SSR Pinion Bearing Parts and Q&A

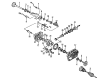

- Q: How to replace the drive pinion bearings on 2004 Chevrolet SSR?A: Vehicle quality depends on properly replacing the drive pinion bearings according to this procedure. Start by elevating the vehicle then stripping the Differential assembly with the drive pinion from the axle housing. The Pinion Bearing remover (J 45871) should be installed first on the Pinion Bearing before using the split-plate bearing puller (J 22912-01) placed upside down around the j 45871 to force the bearing off the pinion. Use a combination of a hammer with brass drift and extract both outer and inner Pinion Bearing cups from the axle housing until they are completely removed. Install the outer Pinion Bearing cup through the combination of rear Pinion Bearing race installer (J 8611-01) and universal driver handle (J 8092) setup followed by using rear Pinion Bearing race installer (J 8608) together with j 8092 for installing the inner cup. The selective shim installation must occur after inserting it between the inner Pinion Bearing along with the gear shoulder. Fit the inner Pinion Bearing into position with the pinion cone and side bearing installer (J 24433) until the cone rests on top of the selected shim followed by a new collapsible spacer. Insert the pinion axle into the housing until settling behind the outer bearing cup and new oil seal through the use of the extension housing oil pump/seal installer (J 38694). Before installing the pinion yoke sealant (GM P/N 12346004 or Canadian P/N 10953480) should be applied to the splines. After that the yoke should be aligned based on removal marks before seating with a soft-faced hammer. The flange and pulley holding tool (J 8614-01) must be used to tighten the nut while you rotate the pinion to achieve proper bearing seating as end play reaches the point where it is just taken up. Measure the torque while rotating with an inch-pound torque wrench until it reaches a torque range of 1.0 - 2.3 nm for utilized bearings or 1.7 - 3.4 nm for fresh bearings. After torque has reached specs reuse the pinion nut in small adjustments until the torque limit is met then move the pinion several times to guarantee bearing seating. Proceed by putting back the Differential assembly and brake components, tire assemblies and lubricating the axle while lowering the vehicle.