ChevyParts

My Garage

My Account

Cart

OEM GMC Distributor

Ignition Distributor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

10 Distributors found

GMC Distributor Part Number: 1103521

$109.22 MSRP: $156.28You Save: $47.06 (31%)GMC Distributor Assembly Part Number: 19179576

$304.49 MSRP: $554.62You Save: $250.13 (46%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Distributor Assembly, (Remanufacture); Distributor

- Replaces: 01104059, 01104052, 1104052, 1104059

GMC Distributor Assembly Part Number: 12598210

Product Specifications- Other Name: Distributor; Distributor, Ignition

- Replaces: 01104057, 01104078, 01104050, 1104050, 1104078, 1104057, 93441559

GMC Distributor Part Number: 1103620

GMC Distributor Part Number: 1103570

Product Specifications- Other Name: Distributor, Ignition

GMC Distributor Part Number: 1103546

Product Specifications- Other Name: Dist

GMC Distributor Part Number: 1103520

Product Specifications- Other Name: Dist

GMC Distributor Part Number: 1103482

GMC Distributor Part Number: 1103480

GMC Distributor Assembly Part Number: 94672691

Product Specifications- Other Name: Starter; Distributor; Distributor, Ignition

- Replaces: 01104058, 01104051, 01104079, 1104058, 93441558, 1104079, 1103977, 1104051, 12570425

GMC Distributor

Choose OEM Distributor, you're making the optimal decision for superior quality and perfect performance. You can feel confident because each component goes through stringent quality checks. Every part is carefully built to comply with GMC's factory specifications. You'll enjoy a smooth, worry-free installation that fits just right. At ChevyPartsDeal.com, you'll find it easy to get top-quality OEM GMC Distributor. You can shop at highly competitive prices and protect your budget. All our genuine GMC parts include a dependable manufacturer's warranty. You'll also appreciate our straightforward return policy and swift delivery services for extra convenience.

GMC Distributor Parts and Q&A

- Q: How to service and repair the distributor on GMC Savana 2500?A:The distributor repair process needs the removal of the engine cover as its first step. Normal wear shows as cap discoloration combined with white deposits nearby the terminals together with rotor cap yellowing coupled with darkening from carbon accumulation under the rotor segment. Driveability issues will determine the need for replacement. Look for cracks and small holes along with carbon tracks between the terminal traces on the cap. Use the DMM lead connected to the cap terminal to inspect all other terminals and the center carbon ball until testing all secondary terminals. Move the DMM base lead between each terminal while performing these tests. Check and replace the ignition cap when you find resistance readings other than infinity. Terminal inspections should take place for excessive corrosion leading to terminal cleaning before cap replacement if corrosion reaches high levels but normal buildup is expected. The rotor segment requires replacement if significant looseness is detected. Examine the housing for signs of cracks while testing shaft-to-bushing looseness with the shaft inserted into its place before installing a new housing assembly if the shaft shows noticeable movement. Finally, reinstall the engine cover.

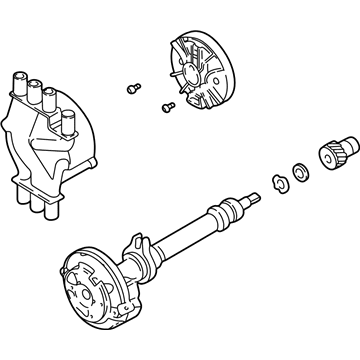

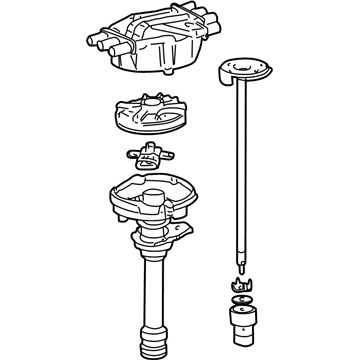

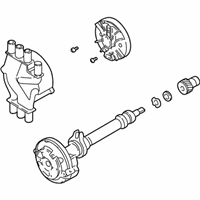

- Q: How to overhaul the distributor on GMC Sierra 1500?A:Prior to dismantling the Distributor start by marking holes in the Distributor driven gear, shaft and rotor for correct assembly. The white paint mark on the Distributor's lower stem must line up with the predrilled hole in the bottom of the gear to position the v6 engine rotor segment correctly. If not, replace the Distributor. Detach rotor screws then take the rotor while writing down the rotor screw hole locations and rotor locator pin hole positions. Fit the square-cut hole of the vane wheel to the cmp sensor before discarding both the cmp sensor screws and the cmp sensor itself. Examine the dimple found below the roll pin hole of one Distributor drive gear side for correct placement when putting components together. A v-block or equivalent fixture should support the drive gear while you use an appropriate punch to extract the roll pin before you remove the gear and its parts including a round washer a tang washer a shim washer and an oil seal. Place the cmp sensor into the square-cut hole of the vane wheel before installing new screws torqued to 2.2 n.m (19 lb in). After that mark the distribution rotor's mounting holes. Screw in the Distributor rotor using index marks while tightening its screws to 1.9 n.m (17 lb in) torque setting. Place the shim washer at the Distributor shaft's bottom before installing the tang washer and round washer. Route the driven gear based on index marks to match the displayed v6 engine configuration while making sure the Distributor's white marker faces the pre-drilled indent on the gear's bottom surface. When the driven gear gets positioned improperly the dimple will appear at a 180-degree position relative to the rotor segment. Before installation place the Distributor drive gear in a v-block while using a suitable punch to install the roll pin. Then install a new oil seal under the mounting flange before putting back the Distributor.