ChevyParts

My Garage

My Account

Cart

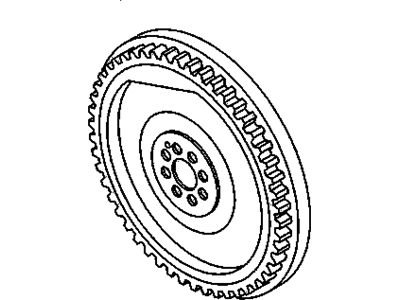

OEM Chevrolet Express 2500 Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

12 Flywheels found

Chevrolet Express 2500 Drive Plate Part Number: 12654640

$132.99 MSRP: $226.41You Save: $93.42 (42%)

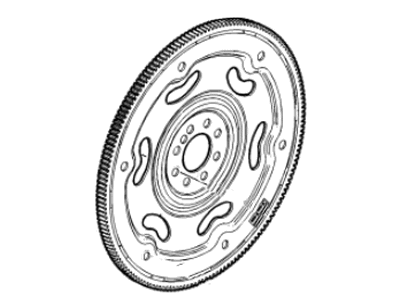

Chevrolet Express 2500 Drive Plate Part Number: 19260102

$87.37 MSRP: $148.77You Save: $61.40 (42%)Ships in 1-2 Business Days

Chevrolet Express 2500 Drive Plate Part Number: 12621644

$227.58 MSRP: $374.89You Save: $147.31 (40%)Ships in 1-3 Business Days

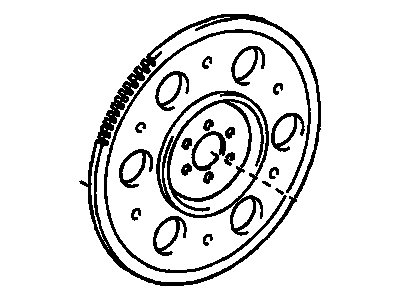

Chevrolet Express 2500 Drive Plate Part Number: 12620099

$68.40 MSRP: $116.44You Save: $48.04 (42%)Ships in 1-2 Business Days

Chevrolet Express 2500 Drive Plate Part Number: 12555640

$211.96 MSRP: $360.86You Save: $148.90 (42%)Ships in 1-2 Business DaysChevrolet Express 2500 Drive Plate Part Number: 12685003

$60.08 MSRP: $103.17You Save: $43.09 (42%)Chevrolet Express 2500 Drive Plate Part Number: 14077157

$158.47 MSRP: $251.60You Save: $93.13 (38%)Chevrolet Express 2500 Drive Plate Part Number: 12557584

$32.24 MSRP: $50.51You Save: $18.27 (37%)Ships in 1-3 Business Days

Chevrolet Express 2500 Drive Plate Part Number: 12557587

Chevrolet Express 2500 Drive Plate Part Number: 12554824

Chevrolet Express 2500 Drive Plate Part Number: 97372295

$412.56 MSRP: $649.14You Save: $236.58 (37%)Chevrolet Express 2500 Drive Plate Part Number: 24586265

$99.14 MSRP: $155.29You Save: $56.15 (37%)

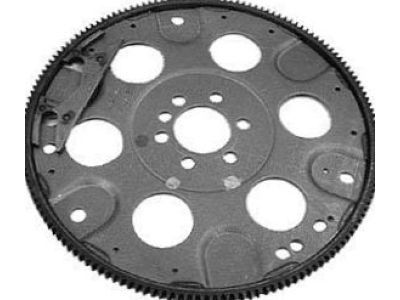

Chevrolet Express 2500 Flywheel

Want to cut long-term maintenance and repair costs? Choose OEM Flywheel. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Express 2500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Express 2500 Flywheel includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Express 2500 Flywheel Parts and Q&A

- Q: How to replace the automatic transmission Flywheel on Chevrolet Express 2500?A:Start by removing the automatic transmission followed by writing down the engine Flywheel position as well as its directional settings during extraction. Rephrase the engine Flywheel bolts first and then detach the automatic transmission engine Flywheel. Clean the engine Flywheel before inspecting it. Install 2 m11x1.5 mm bolts into the threaded spacer holes of the Crankshaft rear while rotating them clockwise to remove the spacer. First install the Crankshaft spacer (if present) and place it at the Crankshaft rear position. Then mount the automatic transmission engine Flywheel onto the Crankshaft and use extended bolts when installing over a Flywheel spacer. The application of threadlock should begin on the engine Flywheel bolt threads followed by their sequential installation and tightening starting at 20 nm (15 lb ft), moving to 50 nm (37 lb ft) before achieving 100 nm (74 lb ft). The automatic transmission needs to be installed when the Flywheel is properly secured.