ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Cobalt Brake Calipers

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

10 Brake Calipers found

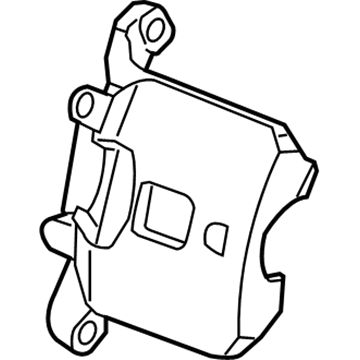

Chevrolet Cobalt Caliper, Driver Side Part Number: 25900763

$341.95 MSRP: $667.86You Save: $325.91 (49%)

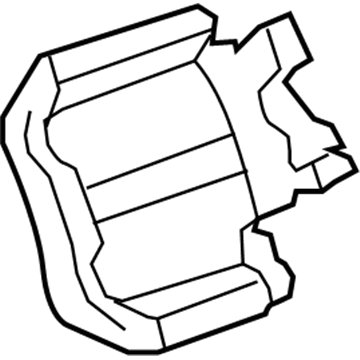

Chevrolet Cobalt Caliper, Passenger Side Part Number: 25900764

$302.34 MSRP: $585.16You Save: $282.82 (49%)Ships in 1-2 Business DaysChevrolet Cobalt Caliper, Green Line, Rear Driver Side Part Number: 19368941

$149.45 MSRP: $280.67You Save: $131.22 (47%)Ships in 1-2 Business Days

Chevrolet Cobalt Caliper, Driver Side Part Number: 25902073

Chevrolet Cobalt Caliper, Passenger Side Part Number: 25902074

Chevrolet Cobalt Caliper, Red Line, Driver Side Part Number: 22720705

Chevrolet Cobalt Caliper, Red Line, Driver Side Part Number: 19368937

Chevrolet Cobalt Caliper, Green Line, Rear Passenger Side Part Number: 19368942

$154.86 MSRP: $277.79You Save: $122.93 (45%)

Chevrolet Cobalt Brake Calipers

Want to cut long-term maintenance and repair costs? Choose OEM Brake Calipers. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Cobalt parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Cobalt Brake Calipers includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

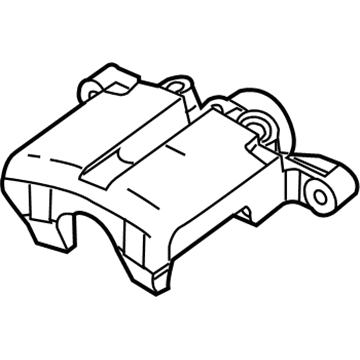

The Brake Caliperss of Chevrolet Cobalt are very important automobile component as it converts hydraulic pressure from the master cylinder into mechanical force. This force will compress the brake pads against the rotors making the vehicle to slow or even stop. Chevrolet Cobalt models utilize two primary types of brake calipers: For example, there can be fixed and floating. The fixed type of caliper has multiple pistons on the inside of the rotor but the floating type can have pistons on one side and slide to apply the pressure needed and this has its demerits such as uneven pad wear if not well checked. Generally the Cobalt brake calipers are manufactured with cast iron bodies while the pistons could be made of steel or phenolic. Performance options are available, upgrades to original equipment calipers, including upgrade in braking and added looks. Its defects can cause brake system problems such as leaks and uneven wear; therefore, the caliper should be inspected and maintained frequently.

Chevrolet Cobalt Brake Calipers Parts and Q&A

- Q: How to replace the front brake calipers with RPO LNF (2.0L) on Chevrolet Cobalt?A:Before replacing the 2.0l front brake caliper you should first lift the vehicle on jack stands and get rid of the tire and wheel. The brake hose needs its bolt and fitting gaskets removed by taking off the brake hose fitting bolt today. When you complete the task discard the worn-out gasket pieces. Secure the brake hose cap to avoid fluid loss and contaminants. Pull out the front disc Brake Pads from their position. Start by removing the wheel caliper bolts before taking the wheel caliper off the wheel knuckle. Threadlocker gm p/n 12345493 (Canadian P/N 10953488) goes on the threads of the bolts and knuckle mounting holes before installing them. Clean and prepare the threads first then apply the threadlocker to 2/3 of the bolt length for 10 minutes to cure. Secure the wheel caliper by installing it on the wheel knuckle and tightening brake caliper bolts to 130 nm (96 lb ft). Mount the brake hose fitting bolt with new copper gaskets placed on both sides together with new fitting gaskets and then connect the brake hose assembly to the brake caliper while tightening the fitting bolt to 40 nm (30 lbft). Put the replacement brake pads back in and perform the hydraulic brake system bleeding process. Press and release the Brake Pedal to 2/3 of its range unpattering while letting go slowly to push brake caliper pistons and pads into their correct position. Place the tire and wheel back on then drop the vehicle to its normal position.

- Q: How to overhaul the front brake calipers on Chevrolet Cobalt?A:First, remove the brake-calliper out of the lorry in such a way that your fingers won't stay in front of the caliper piston(s) while using compressed air since the caliper piston(s) can be readily thrust out which is a major injury confirmation factor. Use clean cloths for padding the interior of the caliper housing while undertaking piston removal, use only a little low-pressure compressed air through the fluid inlet hole to facilitate the ease of pistons sliding out of the bores. Pull off the retaining ring that holds the dust boot into the caliper housing and remove the piston dust boot seal from the seal counterbore in the caliper and throw it away. For the removal of the piston seal from the caliper bore, use a small wooden or plastic tool to take it out and throw it away. Next, take off the bleeder valve cap and blew deer valve. Do not use abrasives to clean out the Brake Caliper Piston and check the caliper bore for cracks, scoring, pitting, high rust, or corrosion. Clean or degrease the caliper piston bore, seal counterbore, and caliper piston using denatured alcohol or its equivalent, and blow with clean, non-lubricated, filtered compressed air. If a light rust or corrosion has occurred try to pick it off with fine emery paper; if not changeable change the caliper assembly. Replace the caliper assembly if there are any cracks, scoring, pitting, excessive rust, or corrosion that is observed in the caliper bore, and inspect the caliper piston for similar damage and replacement if needed. For assembly, you may lubricate the new piston seal with brake fluid saturn p/n 21013073 or equivalent brake fluid of the dot-3 type from a new, sealed container, and use it to install in the caliper bore. Apply small amount (thin layer) of saturn p/n 21013073 or equivalent dot-3 brake fluid onto exterior side of caliper piston before installing bottom half of the caliper piston into caliper bore. The new piston dust boot seal should be placed over the caliper piston and compress the caliper piston into the bottom of the caliper bore while properly seating the piston dust boot seal into the contrabore. Mount the retaining ring that holds the dust boot to the caliper housing then mount the bleeder valve to the caliper with 11nm (97 in lbs) torque and then mount the bleeder valve cap. Finally, you should install the brake caliper back on the vehicle.