ChevyParts

My Garage

My Account

Cart

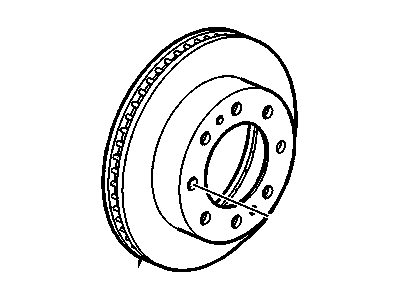

OEM GMC Yukon XL 1500 Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Brake Discs found

GMC Yukon XL 1500 Brake Rotor Part Number: 25757802

$113.95 MSRP: $219.81You Save: $105.86 (49%)Ships in 1-2 Business Days

GMC Yukon XL 1500 Rotor Part Number: 15712803

$170.40 MSRP: $325.78You Save: $155.38 (48%)Ships in 1-2 Business Days

GMC Yukon XL 1500 Rotor Part Number: 15712801

$96.36 MSRP: $180.93You Save: $84.57 (47%)

GMC Yukon XL 1500 Rotor, Front Part Number: 22950036

$121.44 MSRP: $235.71You Save: $114.27 (49%)Ships in 1-3 Business Days

GMC Yukon XL 1500 Rotor, Front Part Number: 19210603

$94.27 MSRP: $182.96You Save: $88.69 (49%)Ships in 1-2 Business Days

GMC Yukon XL 1500 Rotor, Front Part Number: 15942195

$154.61 MSRP: $302.70You Save: $148.09 (49%)Ships in 1-2 Business Days

GMC Yukon XL 1500 Rotor, Rear Part Number: 22968231

GMC Yukon XL 1500 Rotor Part Number: 19211496

GMC Yukon XL 1500 Rotor Part Number: 26088273

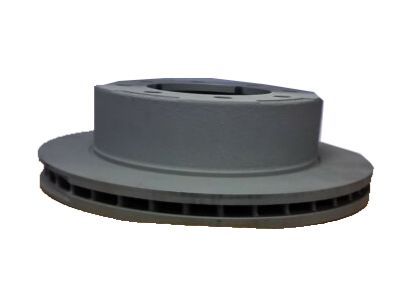

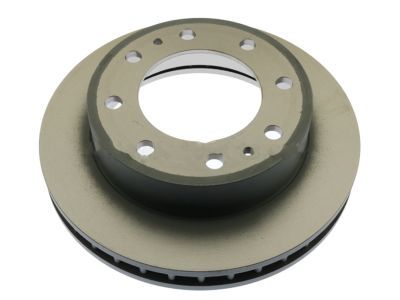

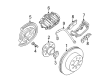

GMC Yukon XL 1500 Brake Disc

Want to cut long-term maintenance and repair costs? Choose OEM Brake Disc. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine GMC Yukon XL 1500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM GMC Yukon XL 1500 Brake Disc includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

GMC Yukon XL 1500 Brake Disc Parts and Q&A

- Q: How to effectively refinish Brake Discs on GMC Yukon XL 1500?A:Use the hub cleaning kit (J 42450-A) to clean the Wheel Bearing and hub, making sure you get rid of rust and foreign material on the surface that could cause lateral runout or brake pulsation when refinishing brake rotors. Use a micrometer to find out where the rotor is the thinnest. When the rotor is thinner than what is allowed, install a new rotor instead of trying to refinish it. Use the rotor resurfacing kit (J 41013) to make sure all rust is removed from the brake rotor flange, then proceed with refinishing the rotor by following your brake lathe's operating instructions. Getting an ideal surface on the rotors is key to having good brake performance. Once the rotor has been machined, smooth it with 120-grit aluminum oxide sandpaper in a non-directional pattern and, if you can, use a non-directional rotor finisher too. Make sure to clean the brake surfaces with gm p/n 12377981 or another equivalent brake parts cleaner.

- Q: How to replace the front brake disc on GMC Yukon XL 1500?A:The first step for front brake rotor replacement tests brake fluid levels in the master cylinder reservoir until the fluid reaches the midway position between maximum and minimum marks. Support the vehicle at a height before removing both tire and wheel assembly. Begin by marking the hub relation of front wheel hub extensions before taking out the hub extension bolts on dual wheel vehicles. A drift or large screwdriver should be used to block rotor movement when removing brake caliper bracket bolts and the caliper and bracket assembly. The caliper assembly must be suspended with heavy gauge wire to protect the brake hose from strain. Before removing the rotor's retaining push nuts check if they exist. If the rotor sticks due to corrosion clean all surfaces first then use penetrating oil before inserting m10x1.5 bolts into rotor threaded holes to break the rotor loose from the hub. The mating surfaces of the new brake rotor and hub flange need thorough cleaning from all rust and contamination while maintaining a free nicks or marks condition on the hub flange. First, mount the rotor before you put the caliper assembly into position. Destreak original adhesive before you clean threads with brake parts cleaner then apply threadlocker gm p/n 12345493 or red loctite #272 to the threads. For 15 series models use 175 nm torque and 300 nm torque applies to 25 and 35 series models during caliper bracket mounting bolt installation. Dual wheel vehicles require installation of the front wheel hub extension following correct alignment then secure the hub extension nuts to 130 nm (96 ft. Lbs.). After installation of tire and wheel assembly users should remove safety stands before lowering the vehicle. After turning off the engine slowly use the brake pedal up to 2/3 of its range before releasing it slowly. Reapply the fee for fifteen seconds till you get firm pedal pressure to let the caliper pistons and pads find their position. Complete the master cylinder reservoir with brake fluid of the recommended grade to achieve the correct operation level.