ChevyParts

My Garage

My Account

Cart

OEM GMC Chassis Wiring Harness Connector

Chassis Harness Connector- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

38 Chassis Wiring Harness Connectors found

GMC Hydraulic Pump Connector, Black Part Number: 19304003

$22.94 MSRP: $43.08You Save: $20.14 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Connector Kit, Wiring Harness *Black; Connector; Lighter, Fuse, Headlamp, Door, Folding, Seat, Blower, Chassis, Radio, A/C, Tail

- Replaces: 12101888, 13586140, 13587132

GMC Connector Wire Part Number: 13584278

$23.47 MSRP: $44.08You Save: $20.61 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Connector, Wiring Harness; Connectors for lamps, sunshade, A/C, inst. panel, door locks, suspension, lighting, chassis, wiring, radio.

- Replaces: 22688558, 12085481

GMC Harness, Black Part Number: 12167120

$35.05 MSRP: $65.82You Save: $30.77 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Connector-W/Leads, 2-Way M. *Black; Connector, Hydraulic, Ambient, Distributor, Wiring, Brake, Emission, Parking, Chassis, Transmission

- Replaces: 12125649, 12162000, 12146134

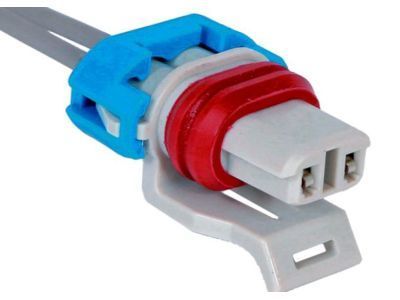

GMC Wire Harness, Black Part Number: 13586139

$31.73 MSRP: $59.58You Save: $27.85 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Connector Assembly, Wiring Harness W/Leads *Black; Headlight Connector; Door Jamb Switch; Lamp Switch Connector; Connector Kit; Connector

- Replaces: 12101864, 21025422

GMC Wire Connector Part Number: 12085535

$20.01 MSRP: $37.58You Save: $17.57 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Connector, Chassis/Body Marker/Hazard; Wire Harness; Sensor Socket; Sensor Connector; Lamp Connector; Harness; Connector

GMC Modulator Connector Part Number: 12102628

$35.35 MSRP: $66.39You Save: $31.04 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Connector, Chassis Electrical; Connector: Door Elec/Vac, HL/Fog, Door/End, Comp Sensors, Heater/AC, Radio, Wire, Fuel

GMC Wire Connector, Black Part Number: 12102900

$37.77 MSRP: $81.76You Save: $43.99 (54%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Connector-W/Leads, 4-Way F. *Black *Math Data; Connector: Rear Compartment Lid Release, Rear View Mirror, Transmission, Air Suspension, Lighting

GMC Temperature Sensor Connector Part Number: 12102620

$21.56 MSRP: $40.47You Save: $18.91 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Connector, Ambient Outside Air Temperature; Air Temperature Sensor Connector; Engine, Instrument, Brake, Sensors, Transmission, Fuse

- Replaces: 12126468

GMC Connector Wire Part Number: 12126452

$31.68 MSRP: $59.50You Save: $27.82 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Connector, Lamp-Fog; Connector; Engine Air Cooling; Capsule/Headlamp/Fog Lamp; Chassis Electrical; Back Up Lamp; Fuse; Standard Parts

GMC Oil Level Sensor, Black, Passenger Side Part Number: 13586114

$25.89 MSRP: $47.49You Save: $21.60 (46%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Connector Assembly, Wiring Harness W/Leads *Black; Windshield Washer Hose Connector; Back Up Light Switch; Oil Dipstick; Solenoid Connector, Speed Sensor, Air Temp Sensor, Washer Pump, Back-Up Switch, etc.

- Position: Passenger Side

- Replaces: 12102747

GMC Socket & Wire, Gray Part Number: 19368034

$27.89 MSRP: $51.42You Save: $23.53 (46%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Connector Kit, Wiring Harness *Gray; Horn Connector; Sensor Harness; Connector; Connector Kit

- Replaces: 15306302, 21022284, 12116958

GMC Socket, Gray Part Number: 19301866

$23.98 MSRP: $44.76You Save: $20.78 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Connector Kit-Wiring Harness *Gray; Headlight Connector; Headlight Socket; Bulb Socket; Connector; Engine Air Cooling; Capsule/Headlamp/Fog Lamp; Chassis Electrical; Rear License Lamp; Radio Control

- Replaces: 12101897

GMC Connector Wire, Black Part Number: 15305916

$73.28 MSRP: $159.99You Save: $86.71 (55%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Connector-W/Leads, 10-Way F. *Black; Headlight Connector; Connector: Body MF, Capsule/HL, Electronic Brake, Emissions, Chassis, Throttle, Wiring, Cruise

GMC Air Mass Sensor Connector Part Number: 13585858

$27.08 MSRP: $49.63You Save: $22.55 (46%)Ships in 1 Business DayProduct Specifications- Other Name: Connector, Wiring Harness; Connector, Engine Air Cooling; Computer Control Sensors; Chassis Electrical; Suspension

- Replaces: 19151498, 88987186

GMC Socket Part Number: 12101898

$29.75 MSRP: $53.32You Save: $23.57 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Connector, Wiring Harness; Headlight Connector; Headlight Socket; Bulb Socket; Connector; Turn Signal, Cornering, Daytime Running, Instrument Cluster, Headlamp, Fog Lamp, Chassis Electrical.

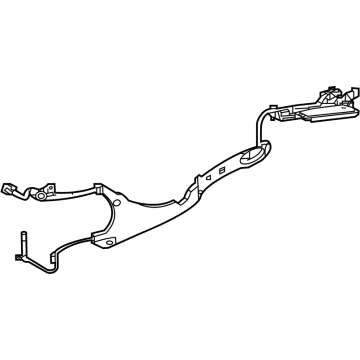

GMC ABS Sensor, Rear Driver Side Part Number: 86807484

$120.97 MSRP: $190.29You Save: $69.32 (37%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Harness Assembly-Chassis Rear Wiring Harness Extension; Harness, Chassis Wiring

- Position: Rear Driver Side

- Replaced by: 85752647

GMC Harness, Rear Part Number: 84882111

$36.51 MSRP: $60.12You Save: $23.61 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Harness Assembly-Chassis Rear Wiring; Harness, Chassis Wiring

- Position: Rear

GMC Engine Harness Part Number: 84246466

$397.24 MSRP: $625.02You Save: $227.78 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Harness Assembly-Chassis Wiring; Harness, Chassis Wiring

- Replaces: 84220141, 84143930, 84143932, 84246464, 84096486, 84096485, 84220143

GMC Connector Retainer Part Number: 13586175

$5.68 MSRP: $8.90You Save: $3.22 (37%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Connector Kit, Wiring Harness; Sensor/Valve Assembly/Front Sensor Retainers; Module Clips; Retainers; Connectors; Clips

- Replaces: 12059296, 12020833

GMC Harness, Rear Part Number: 84619543

$48.80 MSRP: $76.44You Save: $27.64 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Harness Assembly-Chassis Rear Wiring; Harness, Chassis Wiring

- Position: Rear

| Page 1 of 2 |Next >

1-20 of 38 Results

GMC Chassis Wiring Harness Connector

Choose OEM Chassis Wiring Harness Connector, you're making the optimal decision for superior quality and perfect performance. You can feel confident because each component goes through stringent quality checks. Every part is carefully built to comply with GMC's factory specifications. You'll enjoy a smooth, worry-free installation that fits just right. At ChevyPartsDeal.com, you'll find it easy to get top-quality OEM GMC Chassis Wiring Harness Connector. You can shop at highly competitive prices and protect your budget. All our genuine GMC parts include a dependable manufacturer's warranty. You'll also appreciate our straightforward return policy and swift delivery services for extra convenience.

GMC Chassis Wiring Harness Connector conducts steady current between circuits to ensure that the lights on a GMC truck remain on and prevent vibration and moisture. The company was established in the year 1901, and it produces pickup trucks and SUVs that have massive strength boxed frames, powerful powertrains, and work grade suspensions, which can easily shoulder excessive burden on the truck but at the same time it moves like butterfly over potholes. Drivers have access to silent cabins, clever MultiPro tailgate that folds into six helpful modes, surround view cameras, hitch guidance and trailering solutions making towing a simple task. Hard durability testing, rust resistance coating, and regular software upgrades will increase the reliability and resale value and demonstrate the ability and safety concerns underpinning the brand. Powerful but efficient turbo diesel and gas engines, an intuitive infotainment display, smartphone projection, drive modes that allow the driver to work with mud, sand or snow, and powerful brakes make sure of confident braking. To install the Chassis Wiring Harness Connector, you will need to disconnect battery ground, find the corresponding sockets on chassis and inspect each of the terminals and seals of dirt or bends. Install harness along factory tracks, fasten using clips and zip ties out of the heat or edges, and position keys and tab locks and press until the retainer snaps. Apply dielectric grease, as the manual may recommend, reconnect ground cable, perform continuity and functionality tests, clear warning codes, and ensure the loom is strain relieved and has movement.

Related GMC Parts

Browse GMC Chassis Wiring Harness Connector by Models

Sierra 1500 Yukon Sierra 2500 HD Envoy Sonoma Typhoon C1500 Envoy XL Envoy XUV Jimmy K1500 Safari Savana 2500 Savana 3500 Sierra 2500 Sierra 3500 Yukon XL C2500 C3500 K2500 K3500 Savana 1500 Yukon XL 1500 C1500 Suburban C2500 Suburban Hummer EV Pickup K1500 Suburban K2500 Suburban Sierra 1500 Classic Sierra 1500 HD Sierra 1500 HD Classic Sierra 2500 HD Classic Sierra 3500 Classic Sierra 3500 HD Yukon XL 2500