ChevyParts

My Garage

My Account

Cart

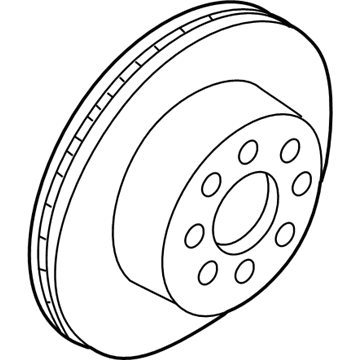

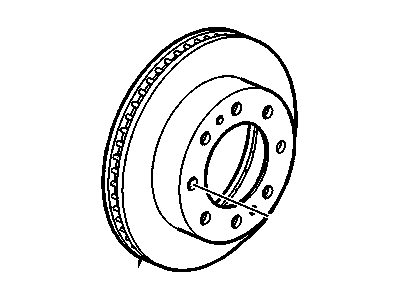

OEM Chevrolet Suburban 1500 Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Brake Discs found

Chevrolet Suburban 1500 Brake Rotor Part Number: 25757802

$113.95 MSRP: $219.81You Save: $105.86 (49%)Ships in 1-2 Business Days

Chevrolet Suburban 1500 Rotor Part Number: 15712803

$170.40 MSRP: $325.78You Save: $155.38 (48%)Ships in 1-2 Business Days

Chevrolet Suburban 1500 Rotor Part Number: 15712801

$96.36 MSRP: $180.93You Save: $84.57 (47%)

Chevrolet Suburban 1500 Rotor, Front Part Number: 22950036

$121.44 MSRP: $235.71You Save: $114.27 (49%)Ships in 1-3 Business Days

Chevrolet Suburban 1500 Rotor, Front Part Number: 19210603

$94.27 MSRP: $182.96You Save: $88.69 (49%)Ships in 1-2 Business Days

Chevrolet Suburban 1500 Rotor, Front Part Number: 15942195

$154.61 MSRP: $302.70You Save: $148.09 (49%)Ships in 1-2 Business Days

Chevrolet Suburban 1500 Rotor Part Number: 15769474

$150.87 MSRP: $292.81You Save: $141.94 (49%)Chevrolet Suburban 1500 Rotor, Front Part Number: 84587921

$136.48 MSRP: $264.90You Save: $128.42 (49%)Ships in 1-2 Business Days

Chevrolet Suburban 1500 Rotor, Rear Part Number: 22968231

Chevrolet Suburban 1500 Rotor Part Number: 19211496

Chevrolet Suburban 1500 Rotor Part Number: 26088273

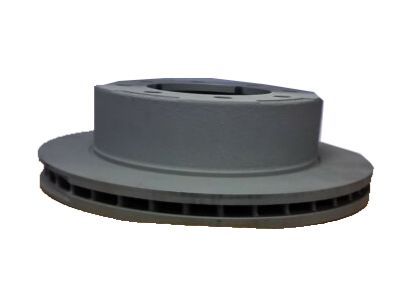

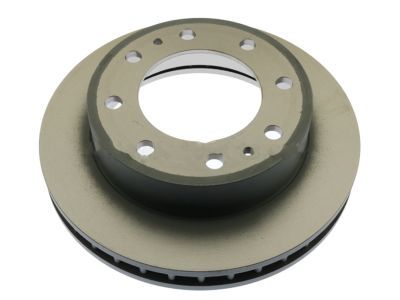

Chevrolet Suburban 1500 Brake Disc

Want to cut long-term maintenance and repair costs? Choose OEM Brake Disc. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Suburban 1500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Suburban 1500 Brake Disc includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Suburban 1500 Brake Disc Parts and Q&A

- Q: How to replace the front brake disc splash shield on Chevrolet Suburban 1500?A:The proper lifting solution should be used to elevate and support the vehicle before dismantling its front disc brake splash shield. The first step requires removing the tire together with the wheel assembly before extracting the hub and bearing assembly unit. The procedure for the 15 series requires you to remove the splash shield before working on the 25 series splash shield. The installation process starts by setting down the 15 series splash shield followed by placement of the 25 series one. Install the hub and bearing components first then continue with tire along with wheel assembly installation. The vehicle can be lowered by removing the safety stands at the end of the operation.

- Q: How to service and repair the Brake Disc on Chevrolet Suburban 1500?A:Before working on the Brake Disc, make sure that nothing on the caliper or caliper bracket can rotate with the rest of the system. Undo the conical disc washers (J 45101-100) and the lug nuts installed during the assembled lateral runout procedure. Check the surface where the hub/axle flange joins with the Brake Disc to make sure it is clean. Following the instructions from the manufacturer, set up the lathe and begin refinishing the Brake Disc, watching the thickness after every cut. The Brake Disc needs to be replaced if it is thinner than the minimum after you refinish it. After you have finished refinishing, use the proper speed setting to apply a non-directional finish on the disc; in case the lathe includes a non-directional finishing attachment, use 120 grit aluminum oxide sandpaper, or opt for a sanding block with 150 grit aluminum oxide sandpaper if it does not. Make sure to clean all sides of the Brake Disc's friction surfaces using denatured alcohol or a suitable brake cleaner. As soon as the lathe comes off the vehicle, use a ruler to see if the assembled lro of the disc is within limits. If the measurement goes over the maximum limit, more adjustments need to be done. If your lro measurement is acceptable after refinishing, attach the brake caliper before pressing the brake several times, and take off the disc washers along with the lug nuts.