ChevyParts

My Garage

My Account

Cart

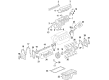

OEM Chevrolet Express 3500 Rocker Arm

Engine Rocker Arm- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Rocker Arms found

Chevrolet Express 3500 Rocker Arms Part Number: 23500074

$19.84 MSRP: $32.68You Save: $12.84 (40%)Ships in 1-2 Business Days

Chevrolet Express 3500 Rocker Arms Part Number: 12619829

$15.74 MSRP: $25.93You Save: $10.19 (40%)Ships in 1-2 Business Days

Chevrolet Express 3500 Rocker Arms Part Number: 10214664

$14.44 MSRP: $23.79You Save: $9.35 (40%)Ships in 1-2 Business DaysChevrolet Express 3500 Rocker Arms Part Number: 97365293

$80.98 MSRP: $162.59You Save: $81.61 (51%)Ships in 1-3 Business DaysChevrolet Express 3500 Rocker Arms Part Number: 12696105

$13.64 MSRP: $22.47You Save: $8.83 (40%)Ships in 1-2 Business DaysChevrolet Express 3500 Rocker Arms Part Number: 12625214

$37.35 MSRP: $58.51You Save: $21.16 (37%)Ships in 1-3 Business DaysChevrolet Express 3500 Rocker Arms Part Number: 12556298

$26.68 MSRP: $43.96You Save: $17.28 (40%)Ships in 1-2 Business DaysChevrolet Express 3500 Rocker Arms Part Number: 12523971

Chevrolet Express 3500 Rocker Arms Part Number: 98004537

$111.09 MSRP: $174.02You Save: $62.93 (37%)

Chevrolet Express 3500 Rocker Arm

Want to cut long-term maintenance and repair costs? Choose OEM Rocker Arm. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Express 3500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Express 3500 Rocker Arm includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Express 3500 Rocker Arm Parts and Q&A

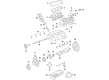

- Q: How to replace the valve rocker arm and push rods on Chevrolet Express 3500?A:The replacement of valve rocker arms and pushrods begins with removing the valve Rocker Arm cover so you can organize valve rocker arms and pushrods with the pivot support in a rack where they can retain their original positions. The maintenance sequence starts with removing bolts from valve rocker arms and proceeding with the removal of valve rocker arms and valve Rocker Arm pivot support alongside pushrods. The inspection and cleaning process applies to valve rocker arms as well as pushrods. During the installation sequence apply clean engine oil to valve rocker arms and pushrods and to also coat the valve Rocker Arm bolt flange. Properly set the pushrod sockets in the valve lifters while the Rocker Arm ends into position before tightening the bolt yet. The number one piston has to reach top dead center (TDC) of compression stroke for the Crankshaft sprocket key to align at the 1:30 position while the cylinder number one rocker arms are off lobe lift. Tighten the Rocker Arm bolts for exhaust cylinders 1 and 2 and 7 and 8 to 30 nm while the intake bolts for 1 and 3 and 4 and 5 receive the same torque value when the engine rests in number one firing configuration. Next proceed with rotating the Crankshaft 360 degrees followed by torque tightening the valve Rocker Arm bolts on cylinders 3, 4, 5, 6 exhaust to 30 nm (22 ft. Lbs.) and cylinders 2, 6, 7, 8 intake to 30 nm (22 ft. Lbs.). The installation process of the valve Rocker Arm cover completes the procedure.

- Q: How to service and repair the rocker arm assembly on Chevrolet Express 3500?A:You should start servicing and repairing the Rocker Arm assembly by removing the valve Rocker Arm cover then carefully storing your removed components for reconstruction. Then remove the valve Rocker Arm nut from the location. When replacing the valve Pushrod only the valve Rocker Arm needs to be loosened enough to allow the Rocker Arm rotation from the Pushrod position before removing the component. Clear all valve Rocker Arm components as well as the valve Rocker Arm ball before inspecting and cleaning all parts. Valve rocker arms and pushrods return to their appropriate locations followed by valve lash adjustment then valve Rocker Arm covers installation.