ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Avalanche 1500 Torsion Bar

Suspension Torsion Bar- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Torsion Bars found

Chevrolet Avalanche 1500 Torsion Bar, Front Passenger Side Part Number: 19332946

$257.82 MSRP: $405.67You Save: $147.85 (37%)

Chevrolet Avalanche 1500 Torsion Bar, Front Driver Side Part Number: 19332945

$257.82 MSRP: $405.67You Save: $147.85 (37%)

Chevrolet Avalanche 1500 Torsion Bar

Want to cut long-term maintenance and repair costs? Choose OEM Torsion Bar. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Avalanche 1500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Avalanche 1500 Torsion Bar includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

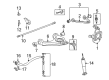

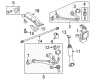

Chevrolet Avalanche 1500 Torsion Bar Parts and Q&A

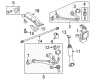

- Q: How to replace the torsion bar on Chevrolet Avalanche 1500?A:First, lift and support the vehicle to replace the Torsion Bar. Beware when dealing with the torsion bars, take care of their coating not to ruin it which will eventually cause the bars to break. After you have uninstalled the lower a- frame torque arm , installing the Torsion Bar unloading/loading tool (J 36202) to the adjustment arm and the cross member this will help you to increase the tension on the adjustment arm until the load is removed from the adjustment bolt and the adjuster nut. Mark the adjustment bolt and note down the number of turns needed for removal then remove the adjustment bolt and adjuster nut. After taking out the j 36202, allow the Torsion Bar to unload and move it forward to clear the adjustment arm, and support the adjustment arm as it releases. Next, take off the Torsion Bar crossmember bolts from the weld nuts and take out the torsion bars marking their positions to the lefts and rights as they are different. For installation, mount torsion bars to lower Control Arm, bolt the Torsion Bar crossmember to the lower Control Arm onto the crossmember bolts and tighten these are hitting up against the weld nuts and tightening up against the weld nuts to 95umann (nanometer) 70 (lb ft) of torque. Supporting the adjustment arm, slide the Torsion Bar to rear until fully engage the adjustment arm, then reinstall the j 36202 to adjustment arm and crossmember to load Torsion Bar. Fix the adjustment bolt and adjuster nut, which should be in the exact same number of turns like when removing it. Remove the j 36202 to relieve the pressure on the Torsion Bar till the pressure is absorbed by adjustment bolt. Finally, take off the safety stands, lower the vehicle, and take the measurement of z height adjust the adjustment bolt in a clockwise direction to increase and a counter clockwise direction to decrease the z height accordingly.