ChevyParts

My Garage

My Account

Cart

OEM Cadillac Timing Belt

Engine Timing Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Timing Belts found

Cadillac Timing Belt Part Number: 55493234

$21.28 MSRP: $35.05You Save: $13.77 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Belt, Oil Pump; Timing Belt Kit; Belt; Belt, Engine Oil Pump

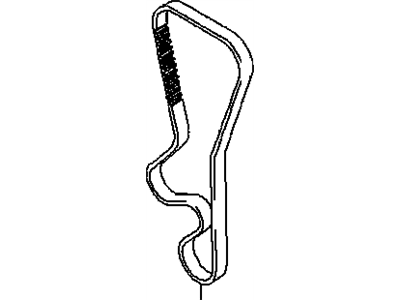

Cadillac Timing Belt Part Number: 90234902

Product Specifications- Other Name: Belt, Engine Timing; Timing Belt Kit

Cadillac Timing Belt Part Number: 95522522

$87.80 MSRP: $137.51You Save: $49.71 (37%)Product Specifications- Other Name: Belt, Engine Timing

- Replaces: 09128500, 9128500, 90530599

Cadillac Timing Belt

Choose OEM Timing Belt, you're making the optimal decision for superior quality and perfect performance. You can feel confident because each component goes through stringent quality checks. Every part is carefully built to comply with Cadillac's factory specifications. You'll enjoy a smooth, worry-free installation that fits just right. At ChevyPartsDeal.com, you'll find it easy to get top-quality OEM Cadillac Timing Belt. You can shop at highly competitive prices and protect your budget. All our genuine Cadillac parts include a dependable manufacturer's warranty. You'll also appreciate our straightforward return policy and swift delivery services for extra convenience.

Cadillac Timing Belt Parts and Q&A

- Q: How to replace the timing belt on Cadillac CTS?A:The process to replace a Timing Belt needs the use of particular tools including Timing Belt alignment kit (J 42069), crank hub torx© socket (J 42098) and additional components j 42069-10, j 42069-1, j 42069-2, j 42069-30, and j 42069-40. Any observed cracks or wear on the Timing Belt will lead to it being considered unfit for reuse. Start the replacement by taking off both the Timing Belt cover along with the crankshaft balancer. You should rotate the crankshaft clockwise using the crank hub torx© socket (J 42098) until the #1 cylinder reaches top dead center during compression stroke. The goal is to see that the reference marks on both camshaft gears line up with the notches found on both the rear Timing Belt cover and the crankshaft sprocket. The crankshaft needs to rotate counterclockwise until the crankshaft reaches 60 degrees before top dead center (BTDC) while maintaining the moveable lever toward its forward position. The Timing Belt alignment kit (J 42069-10) should be mounted onto the crankshaft sprocket while rotating the crankshaft clockwise until the tool lever touches the water pump pulley flange. This action locks the moveable lever into place. You should use the tools j 42069-1 and j 42069-2 to attach them to the camshaft gears but only after loosening the upper idler pulley when necessary for correct fit. Begin by removing the lower idler pulley combined with its adjacent spacer while also undoing the Timing Belt Tensioner nut and the upper idler pulley bolt. Experienced personnel must maintain separate bodily action on the camshaft and crankshaft to prevent their inter-sector contact. For new or used Timing Belt installation, both rotational directions must align with crankshaft motion and the belt guide marks need to be utilized for proper fit. To prevent belt jumping the sprocket teeth install the Timing Belt alignment kit (J 42069-30) while guiding the belt to enter the Timing Belt Tensioner then the camshaft gears and re-install the lower idler pulley with its spacer. Use crank hub torx© socket (J 42098) to turn the crankshaft into top dead center while applying 40 nm of torque (30 lb ft) to the lower idler pulley bolt. Sustain tension on the Timing Belt at the upper idler pulley until initial tension reaches its specified level while checking the alignment marks. After removing tools j 42069-30, j 42069-1 and j 42069-2 the mechanic rotates the crankshaft ahead to 60 degrees btdc prior to reinstallation of the Timing Belt alignment kit (J 42069-10). Secure the moveable lever while checking the reference marks alignment on both camshaft gears. The necessary adjustment steps should be followed but when no adjustment is needed final Timing Belt tension should be set before tightening the upper idler pulley bolt to 40 nm (30 lb ft). The maintenance process concludes by uninstalling tools j 42069-10 and j 42069-20 followed by reinstallation of the crankshaft balancer and Timing Belt cover.