ChevyParts

My Garage

My Account

Cart

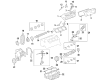

OEM Buick Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

30 Rod Bearings found

Buick Bearing Set, Blue Part Number: 55568532

$76.28 MSRP: $119.48You Save: $43.20 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Bearing Kit, Engine Connecting Rod; Rod Bearing; Bearing; Bearings

Buick Connecting Rod Bearing Part Number: 12657438

$12.31 MSRP: $19.55You Save: $7.24 (38%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Bearing Kit, Connecting Rod; Bearing Set

- Replaced by: 12668645

Buick Connecting Rod Bearing Part Number: 12643667

$10.51 MSRP: $17.32You Save: $6.81 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing Kit, Engine Connecting Rod; Rod Bearing; Bearing; Bearings

Buick Connecting Rod Bearing Part Number: 12559363

$26.20 MSRP: $43.16You Save: $16.96 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing Kit, Connecting Rod; Rod Bearing; Bearing Set; Bearings; Bearing Kit, Engine Connecting Rod

- Replaces: 03543901, 3543901

Buick Bearings Part Number: 89017791

$20.45 MSRP: $33.69You Save: $13.24 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing Kit, Connecting Rod; Rod Bearing; Bearing Kit, Engine Connecting Rod

- Replaces: 12482716

Buick Bearing Part Number: 89017573

$15.26 MSRP: $25.14You Save: $9.88 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Bearing Kit, Connecting Rod; Rod Bearing; Bearings; Bearing Kit, Engine Connecting Rod; Bearing, Engine Connecting Rod

- Replaces: 12493714, 12493712

Buick Connecting Rod Bearing Part Number: 12698279

$8.15 MSRP: $12.94You Save: $4.79 (38%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Bearing Kit, Engine Connecting Rod; Rod Bearing

Buick Bearing Set Part Number: 55488264

$21.69 MSRP: $33.99You Save: $12.30 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Bearing Kit, Engine Connecting Rod; Rod Bearing

Buick Bearing Set, White Part Number: 55568533

$83.82 MSRP: $138.06You Save: $54.24 (40%)Product Specifications- Other Name: Bearing Kit, Engine Connecting Rod; Rod Bearing; Bearing; Bearings

- Replaces: 25195606

Buick Connecting Rod Bearing Part Number: 55511850

$6.71 MSRP: $10.50You Save: $3.79 (37%)Product Specifications- Other Name: Bearing Kit, Engine Connecting Rod; Rod Bearing

Buick Rod Bearings Part Number: 89017700

$15.30 MSRP: $25.21You Save: $9.91 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing Kit, Connecting Rod; Rod Bearing; Connecting Rod Bearing; Bearing Set; Bearings; Bearing Kit, Engine Connecting Rod; Bearing, Engine Connecting Rod

- Replaces: 12480819, 12537418, 89017565, 18005399

Buick Bearings Part Number: 12329989

$13.11 MSRP: $18.75You Save: $5.64 (31%)Product Specifications- Other Name: Bearing; Rod Bearing

Buick Connecting Rod Bearing Part Number: 52285320

$18.06 MSRP: $36.26You Save: $18.20 (51%)Product Specifications- Other Name: Bearing, Engine Connecting Rod; Rod Bearing; Bearings

- Replaced by: 93209483

Buick Bearings Part Number: 89060553

$6.22 MSRP: $9.74You Save: $3.52 (37%)Product Specifications- Other Name: Bearing Kit, Connecting Rod; Rod Bearing; Bearing Kit, Engine Connecting Rod

- Replaces: 12586085

Buick Connecting Rod Bearing Part Number: 12480255

$0.38 MSRP: $0.59You Save: $0.21 (36%)Product Specifications- Other Name: Bearing Kit, Connecting Rod; Rod Bearing; Bearings; Bearing Kit, Engine Connecting Rod

- Replaces: 12518302

Buick Bearings Part Number: 12355680

Product Specifications- Other Name: Bearing Kit, Engine Connecting Rod; Rod Bearing

Buick Main Bearings, Green Part Number: 94625719

Product Specifications- Other Name: Bearing Kit, Engine Crankshaft Main; Main Bearing; Bearings

- Replaced by: 93209472

Buick Connecting Rod Bearing Part Number: 12329830

Product Specifications- Other Name: Bearing; Rod Bearing; Bearings

Buick Bearings Part Number: 18008494

Product Specifications- Other Name: Bearing Kit, Engine Connecting Rod; Rod Bearing; Bearing, Engine Connecting Rod

Buick Connecting Rod Bearing Part Number: 52284262

Product Specifications- Other Name: Bearing, Engine Connecting Rod; Rod Bearing; Bearing Kit, Engine Connecting Rod

- Replaces: 12508913

| Page 1 of 2 |Next >

1-20 of 30 Results

Buick Rod Bearing

Choose OEM Rod Bearing, you're making the optimal decision for superior quality and perfect performance. You can feel confident because each component goes through stringent quality checks. Every part is carefully built to comply with Buick's factory specifications. You'll enjoy a smooth, worry-free installation that fits just right. At ChevyPartsDeal.com, you'll find it easy to get top-quality OEM Buick Rod Bearing. You can shop at highly competitive prices and protect your budget. All our genuine Buick parts include a dependable manufacturer's warranty. You'll also appreciate our straightforward return policy and swift delivery services for extra convenience.

Buick Rod Bearing Parts and Q&A

- Q: How to Service a Rod Bearing on Buick Century?A:To replace the connecting Rod Bearing, the Oil Pan, Oil Pump and the Crankshaft oil deflector are removed in the first place. Rotate the Crankshaft until the Piston and rod assembly to be maintained is at bottom dead center (BDC), making sure you mark the connecting rod and its cap with matchmarks or numbers for accuracy of reassembly. Take off the connecting rod nuts, the connecting rod cap, the lower connecting Rod Bearing, and do not forget to apply a thread protector to protect the Crankshaft journal. Next, install the connecting rod bolt guide set (J5239) allowing the Piston and connecting rod to be raised up the cylinder so to get to the upper connecting rod that is to be taken out next. Cleaning oil off the connecting rod bearings and Crankshaft connecting rod journal, inspect the connecting rod bearings, connecting rod cap, connecting rod and Crankshaft connecting rod journal. For installation, meet the connecting Rod Bearing's upper part, install the connecting rod and apply its inside surfaces with the new engine oil. By using the connecting rod bolt guide set (J5239), pull the Piston and rod assembly down to the Crankshaft and remove the guide set after which install the lower connecting Rod Bearing in the connecting rod cap, lubricate their inside surfaces with new engine oil as well. I would recheck the angle with electronic torque angle meter (J36660-A) hooked to the connecting rods and turn the nuts an additional 75 degrees while tightening to 20 nm (15 ft. Lbs.) on the lower connecting rod nut and bearing. Measure the connecting rod clearance by loading all the connecting rod bearings into the engine, and tapping each of the connecting rods parallel to the crankpin to decay clearance, follow by measuring the side clearance between the connecting rod caps with the feeler gauge or dial indicator. Lastly, fit the Crankshaft oil deflector, Oil Pump, and Oil Pan.

- Q: What additional engine repair information can be found for the service and repair of the connecting rod bearing on Buick Regal?A:For information on repairing and servicing bearing on connecting rods, additional engine repair directions are available elsewhere. When an internal engine component is not given a special service procedure, it shows that the manufacturer has not prepared one. To do engine overhaul, important steps in unit repair include service operations, machining, cleaning, inspection and fitting, including boring and honing the cylinder, fitting connecting rod with bearings, crankshaft with bearings and camshaft bearings, disassembling the connecting rod and Piston, cylinder head, valve-related components and Oil Pump, fitting in Piston and rings and fixing thread damage, as well as valve and seat grinding tasks found during Cylinder Head assembly. Chain, belt and gears are the main parts in timing components service.