ChevyParts

My Garage

My Account

Cart

OEM Buick Harmonic Balancer

Engine Harmonic Balancer- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

66 Harmonic Balancers found

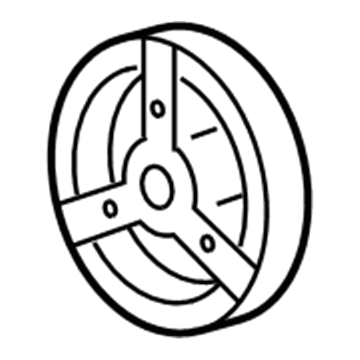

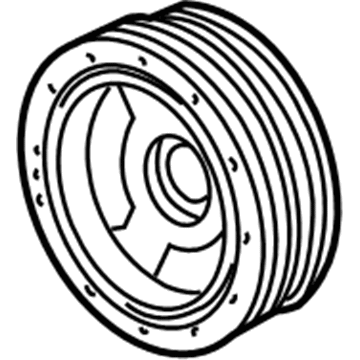

Buick Crankshaft Pulley Part Number: 12583151

$105.13 MSRP: $166.91You Save: $61.78 (38%)Product Specifications- Other Name: Damper, Engine Crankshaft And Camshaft Balancer; Harmonic Balancer Puller; Harmonic Balancer; Vibration Damper; Crankshaft Balance Pulley; Engine Crankshaft and Camshaft Balancer.

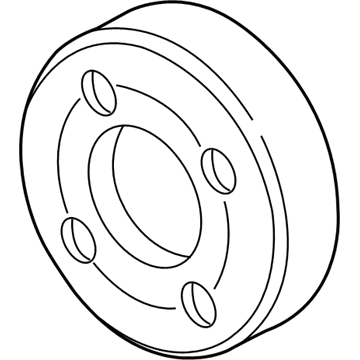

Buick Crankshaft Balance Part Number: 12618249

$137.47 MSRP: $258.16You Save: $120.69 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pulley-Water Pump; Serpentine Belt Drive Kit; Water Pump Pulley; Pulley

- Replaced by: 19367394

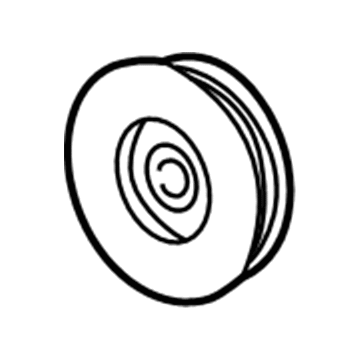

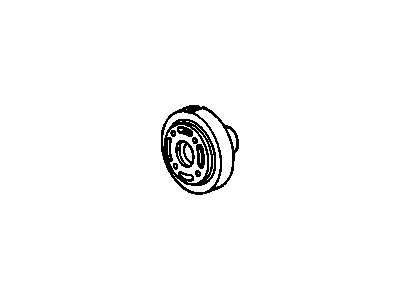

Buick Vibration Damper Part Number: 12571619

$113.11 MSRP: $186.33You Save: $73.22 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pulley; Harmonic Balancer; Balancer

- Replaced by: 12578069

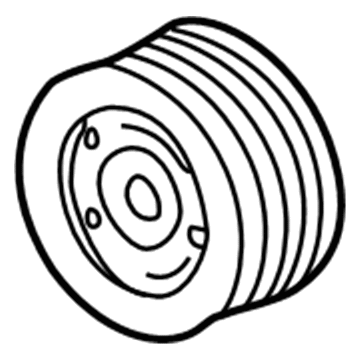

Buick Balancer Part Number: 25203989

$42.71 MSRP: $67.80You Save: $25.09 (38%)Product Specifications- Other Name: Pulley; Balancer, Engine Crankshaft

Buick Crankshaft Pulley Part Number: 12702118

$87.59 MSRP: $144.29You Save: $56.70 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pulley; Vibration Damper; Balancer; Balancer, Engine Crankshaft And Camshaft Balancer

- Replaces: 12565992

Buick Vibration Damper Part Number: 55512745

$40.16 MSRP: $66.15You Save: $25.99 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pulley; Harmonic Balancer; Balancer; Balancer, Engine Crankshaft

Buick Vibration Damper Part Number: 12707253

$55.33 MSRP: $91.13You Save: $35.80 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pulley; Harmonic Balancer; Balancer; Balancer, Engine Crankshaft

Buick Vibration Damper Part Number: 12578069

$118.42 MSRP: $186.33You Save: $67.91 (37%)Product Specifications- Other Name: Pulley; Harmonic Balancer; Balancer; Balancer, Engine Crankshaft And Camshaft Balancer

- Replaces: 12571619

Buick Pulley Part Number: 14023148

Product Specifications- Other Name: Pulley, Engine Crankshaft And Camshaft Balancer; Pulley Assembly, Engine Crankshaft; Pulley, Engine Crankshaft

Buick Crankshaft Pulley Part Number: 88960262

Product Specifications- Other Name: Damper, Engine Crankshaft And Camshaft Balancer; Harmonic Balancer Puller; Harmonic Balancer; Crankshaft Balance; Pulley; Balancer; Balancer, Engine Crankshaft And Camshaft Balancer

- Replaces: 24503067

Buick Vibration Damper Part Number: 12634105

Product Specifications- Other Name: Pulley; Harmonic Balancer; Crankshaft Balance; Balancer

- Replaces: 12576652, 12553112

Buick Pulley Part Number: 560328

Product Specifications- Other Name: Pulley Assembly- (3 Groove 7.320 Pd); Pulley, Engine Crankshaft And Camshaft Balancer; Pulley, Fan And Coolant Pump; Pulley, Engine Crankshaft

Buick Vibration Damper Part Number: 88960263

Product Specifications- Other Name: Damper, Engine Crankshaft And Camshaft Balancer; Crankshaft Damper; Crankshaft Balance; Balancer, Engine Crankshaft And Camshaft Balancer

- Replaces: 24504738

Buick Crankshaft Pulley Part Number: 88959268

Product Specifications- Other Name: Damper, Engine Crankshaft And Camshaft Balancer; Harmonic Balancer Puller; Harmonic Balancer; Vibration Damper; Crankshaft Damper; Pulley; Engine Crankshaft and Camshaft Balancer.

- Replaces: 24501201

Buick Crankshaft Pulley Part Number: 12498527

Product Specifications- Other Name: Balancer Kit, Engine Crankshaft And Camshaft Balancer; Harmonic Balancer Puller; Harmonic Balancer; Balancer

- Replaces: 12339997

Buick Crankshaft Pulley Part Number: 12563267

Product Specifications- Other Name: Pulley; Harmonic Balancer Puller; Harmonic Balancer; Vibration Damper; Crankshaft Balance; Balancer; Balancer, Engine Crankshaft And Camshaft Balancer

- Replaces: 24504737, 24507558

Buick Crankshaft Pulley Part Number: 12563268

Product Specifications- Other Name: Pulley; Harmonic Balancer Puller; Harmonic Balancer; Vibration Damper; Crankshaft Balance; Balancer; Balancer, Engine Crankshaft And Camshaft Balancer

- Replaces: 24507560

Buick Vibration Damper Part Number: 10146878

Product Specifications- Other Name: Pulley; Crankshaft Balance; Balancer, Engine Crankshaft And Camshaft Balancer

Buick Crankshaft Pulley Part Number: 10027439

Product Specifications- Other Name: Pulley, Engine Crankshaft And Camshaft Balancer; Harmonic Balancer Puller; Pulley

Buick Crankshaft Pulley Part Number: 88960259

Product Specifications- Other Name: Damper, Engine Crankshaft And Camshaft Balancer; Harmonic Balancer Puller; Harmonic Balancer; Vibration Damper; Crankshaft Balance; Pulley; Balancer; Balancer, Engine Crankshaft And Camshaft Balancer

- Replaces: 24501752

| Page 1 of 4 |Next >

1-20 of 66 Results

Buick Harmonic Balancer

Choose OEM Harmonic Balancer, you're making the optimal decision for superior quality and perfect performance. You can feel confident because each component goes through stringent quality checks. Every part is carefully built to comply with Buick's factory specifications. You'll enjoy a smooth, worry-free installation that fits just right. At ChevyPartsDeal.com, you'll find it easy to get top-quality OEM Buick Harmonic Balancer. You can shop at highly competitive prices and protect your budget. All our genuine Buick parts include a dependable manufacturer's warranty. You'll also appreciate our straightforward return policy and swift delivery services for extra convenience.

Buick Harmonic Balancer Parts and Q&A

- Q: How to replace the harmonic balancer on Buick Enclave?A:The crankshaft balancer replacement process begins with uninstallation of the engine mount strut bracket and the Drive Belt and the Starter. The en 46106 (Flywheel Holding Tool) requires insertion into the Starter mount hole followed by right frame support with jackstands. The technician should remove right side frame reinforcement bolts followed by loosening right side frame bolts while lowering the frame down about 2 inches. Prior to removing the crankshaft balancer bolt, place the j 38416-2 (Crankshaft Button) in the crankshaft nose and use the j 41816 (Crankshaft Balancer Remover) to pull off the crankshaft balancer from the crankshaft. While installing the crankshaft balancer use the j 41998-b (Crankshaft Balancer Installer) and its required components but avoid oiling the seal areas or front oil seal of the crankshaft. Lubricate the internal bore of the crankshaft balancer hub before aligning the balancer with the crankshaft and threading the j 41998-b until it engages at least ten threads before pressing the balancer into position. Screw the j 41998-b until the large washer sits firmly against the crankshaft end before discarding the j 41998-b. At this point, thread in the crankshaft balancer bolt and secure it first to 100 nm (74 lb ft) and complete the process by turning it 150 more degrees using j 45059. Install the Starter after en 46106 removal while using engine support fixtures to raise the engine. Then mount the strut bracket before applying the Drive Belt.

- Q: How to replace the harmonic balancer on Buick Regal?A:Videaffects the car demands the disconnection of the negative Battery Cable and the Drive Belt removal. The technician should raise the vehicle followed by removing the right front tire and wheel along with the right engine splash shield and torque converter cover. The repair procedure requires use of the flywheel holder (J 37096) to stabilize the flywheel while removing the crankshaft balancer retaining bolt without detaching the Crankshaft Pulley from the crankshaft balancer because they need to remain as an assembly. Installation of the crankshaft balancer remover (J 38197-A) should follow before removing the crankshaft balancer and then removing the tool (J 38197-A). The application process begins with applying lubricating engine oil both to the crankshaft balancer contact area on the front cover and to the seal surface before inserting the crankshaft balancer. Fasten the crankshaft balancer retainig bolt into place while using the flywheel holder (J 37096) as a safety measure to stop the flywheel from spinning before tightening it to 150 nm (111 ft. Lbs.). Follow this step with the electronic torque angle meter (J 36660-A) tool to rotate the bolt a total of 76 degrees. The mechanic should first remove the flywheel holder (J 37096) to reattach the torque converter cover, right engine splash shield with retainers, right front tire and wheel, lower the vehicle, install the Drive Belt, reinstall the negative Battery Cable, and complete the ckp system variation learn procedure.