ChevyParts

My Garage

My Account

Cart

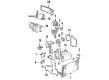

OEM Buick A/C Clutch

Air Conditioning Clutch- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

36 A/C Clutches found

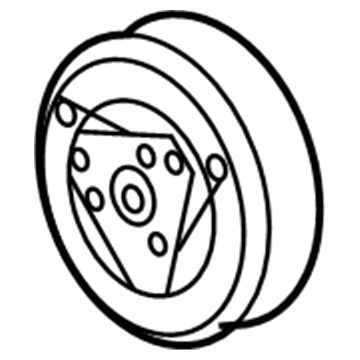

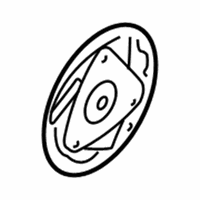

Buick Pulley Part Number: 6552284

$140.68 MSRP: $252.35You Save: $111.67 (45%)Product Specifications- Other Name: Pulley-W/Rotor & Bearing (5.0") P.V.; A/C Compressor Clutch

- Replaced by: 06580047

Buick Coil Assembly Part Number: 89019186

$34.63 MSRP: $102.48You Save: $67.85 (67%)Product Specifications- Other Name: Coil, Air Conditioner Compressor Clutch Actuating; A/C Compressor Clutch; Clutch Coil; Clutch Coil Assembly; Coil & Wire Assembly; Clutch; Coil; Coil, A/C Compressor Clutch Actuating

- Replaces: 6552423, 06552423

Buick Coil Assembly Part Number: 89019185

Product Specifications- Other Name: Coil Assembly, A/C Clutch; A/C Compressor Clutch; Clutch Coil; Clutch Coil Assembly; Coil; Coil, A/C Compressor Clutch Actuating

- Replaces: 06552422, 6552422

Buick Coil Assembly Part Number: 6552649

Product Specifications- Other Name: Coil, A/C Compressor Clutch; Clutch Coil; A/C Compressor Clutch Assembly; Coil & Wire Assembly

Buick Rotor & Bearing Part Number: 2724722

Product Specifications- Other Name: Rotor, A/C Clutch; A/C Compressor Clutch; Rotor; Rotor, A/C Compressor (Internal Parts)

Buick Compressor Pulley Part Number: 6557503

Product Specifications- Other Name: R4 Pulley; A/C Compressor Clutch; Pulley

Buick Clutch Drive Part Number: 6551717

Product Specifications- Other Name: Clutch Drive Assembly; A/C Compressor Clutch; Clutch

Buick Clutch Part Number: 89018605

Product Specifications- Other Name: Clutch Kit, A/C; A/C Compressor Clutch

- Replaces: 10311311

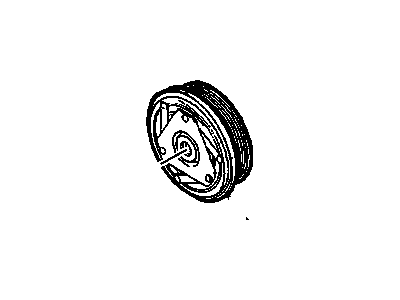

Buick Clutch Kit Part Number: 84364333

$122.61 MSRP: $219.92You Save: $97.31 (45%)Product Specifications- Other Name: Clutch Kit, Air Conditioner Compressor Clutch; A/C Compressor Clutch; Clutch & Pulley; Clutch; Clutch Kit, A/C Compressor Clutch

- Replaced by: 85641373

- Replaces: 23393433

Buick Coil Assembly Part Number: 6550835

Product Specifications- Other Name: Clutch Coil/H; A/C Compressor Clutch; Clutch Coil; Cluster Assembly; Coil & Wire Assembly; Clutch; Coil; Coil, A/C Compressor Clutch Actuating

Buick Coil Part Number: 6552289

Product Specifications- Other Name: Coil, W/Housing Assembly; A/C Compressor Clutch

Buick Hub Assembly Part Number: 5914719

Product Specifications- Other Name: Clutch, A/C; A/C Compressor Clutch; Clutch & Pulley; Drive Assembly; Coil; Compressor Plate; Hub Assembly; A/C Actuating.

Buick Clutch Drive, Front Part Number: 6552372

Product Specifications- Other Name: Clu Front Assembly; A/C Compressor Clutch; Clutch

- Position: Front

- Replaced by: 6581515

Buick Coil Assembly Part Number: 89019188

Product Specifications- Other Name: Coil Assembly, A/C Clutch; A/C Compressor Clutch; Clutch Coil; Clutch Coil Assembly; Coil & Wire Assembly; Clutch; Coil; Coil, A/C Compressor Clutch Actuating

- Replaces: 6552155, 06551997, 6551997

Buick Clutch Coil Part Number: 3091128

Product Specifications- Other Name: Coil & Housing Assembly (High-Amp); A/C Compressor Clutch; Clutch Coil Assembly; Coil & Wire Assembly; Coil

Buick Clutch Part Number: 89018518

Product Specifications- Other Name: Clutch Kit, A/C; A/C Compressor Clutch; Clutch Kit, A/C Compressor Clutch

Buick Clutch Part Number: 10311310

Product Specifications- Other Name: Clutch Assembly-A/C; A/C Compressor Clutch; Clutch, A/C Compressor Clutch

Buick Compressor Pulley Part Number: 6580546

Product Specifications- Other Name: Pulley, A/C Compressor; A/C Compressor Clutch; Pulley W/Bearing; Pulley; Pulley, A/C Compressor Drive/Idler

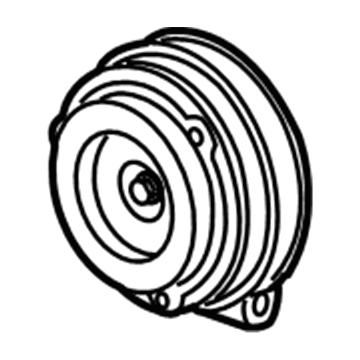

Buick Clutch & Pulley Part Number: 84160278

$124.95 MSRP: $224.12You Save: $99.17 (45%)Product Specifications- Other Name: Clutch Kit, Air Conditioner Compressor Clutch; A/C Compressor Clutch; Clutch; Clutch Kit, A/C Compressor Clutch

Buick Clutch Assembly Part Number: 86807268

$246.59 MSRP: $442.34You Save: $195.75 (45%)Product Specifications- Other Name: Clutch Kit, Air Conditioner Compressor Clutch; Clutch; Clutch Kit, A/C Compressor Clutch

- Replaces: 15926084

| Page 1 of 2 |Next >

1-20 of 36 Results

Buick A/C Clutch

Choose OEM A/C Clutch, you're making the optimal decision for superior quality and perfect performance. You can feel confident because each component goes through stringent quality checks. Every part is carefully built to comply with Buick's factory specifications. You'll enjoy a smooth, worry-free installation that fits just right. At ChevyPartsDeal.com, you'll find it easy to get top-quality OEM Buick A/C Clutch. You can shop at highly competitive prices and protect your budget. All our genuine Buick parts include a dependable manufacturer's warranty. You'll also appreciate our straightforward return policy and swift delivery services for extra convenience.

Buick A/C Clutch Parts and Q&A

- Q: How to replace the A/C Clutch assembly on Buick Enclave?A:A vehicle lift operation will be the initial step to begin replacing the air conditioning clutch assembly. The Drive Belt should come off first before you remove the clutch plate retaining bolt and the clutch plate assembly. Begin by removing the clutch hub/bearing snap ring followed by the clutch hub/bearing assembly. Following this step remove the clutch coil harness retainer. Begin the replacement process by dislodging the snap ring of the clutch coil and afterward extracting the clutch coil from the A/C Compressor. First install the clutch coil onto the A/C Compressor while securing it with snap ring . Repeat the following installation sequence: place the clutch hub/bearing assembly then fit the clutch hub/bearing snap ring. Install the clutch plate assembly avoiding drive plate drag against the pulley while rotating by adding small amounts of oil to the tightest air gap shim beforehand. Maintain a 0.35-0.65 mm (0.014-0.026 in) air gap between the pulley and drive plate by modifying the shim placement. After lowering the vehicle reinstall the Drive Belt then tighten the clutch plate retaining bolt to 18 nm (13 lb ft).

- Q: How to replace the A/C Clutch assembly on Buick LaCrosse?A:Before replacing the compressor clutch assembly begin with accessory Drive Belt removal from the A/C Compressor according to the Drive Belt replacement procedures designed for engine types 3.8l (L26), 3.6l (LY7), or 5.3l (LS4). 3.8l (L26), 3.6l (LY7), or 5.3l (LS4). Start by removing the compressor and lower air deflector while removing three adjustable dowels from the j 37872 compressor clutch holding tool and installing three 5/16x1 inch bolts in their place. Remove the compressor clutch plate bolt after discarding it and proceed by attaching the j 37872 to firmly hold the compressor clutch plate during removal. The j 6083 snap ring pliers permits the removal of the compressor pulley snap ring as well as the compressor pulley and the compressor clutch coil snap ring followed by the compressor clutch coil. To prepare for installation work on the compressor clutch coil follow these steps: first use an m6x1.0 tap to clean the clutch plate bolt threads then blow away debris with compressed air before using the j 6083 to install both the clutch coil and its snap ring. Plug the compressor pulley and its snap ring into place before applying oil onto the clutch drive plate's 0.4 mm (0.016 in) air gap shim which then must be placed inside before installing the compressor clutch plate. As you rotate the drive plate verify that it doesn't scrape against the pulley then use the air gap measurement between pulley and drive plate to adjust the shims for a 0.3-0.6 mm (0.012-0.024 in) gap. Tighten the new clutch drive plate bolt to 12 n.m (106 lb in) while utilizing the j 37872 to hold the compressor clutch plate. The bolt requires colored adhesive to cover at least 5 threads. Expose the lower air deflector following installation of the accessory Drive Belt and specific engine type compressor reinstallation. Finish the work by conducting a leak test on fittings through the j 39400-a halogen leak detector.