ChevyParts

My Garage

My Account

Cart

OEM 2003 Chevrolet Corvette Crankshaft Position Sensor

Engine Crankshaft Position Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Crankshaft Position Sensor found

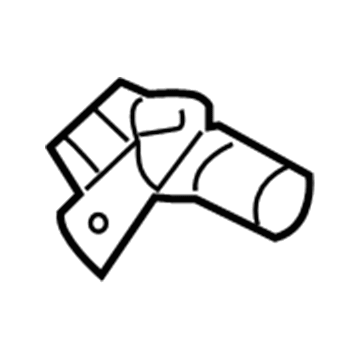

2003 Chevrolet Corvette Crankshaft Position Sensor Part Number: 12560228

$66.20 MSRP: $119.82You Save: $53.62 (45%)Product Specifications- Other Name: Sensor, Distributor (Also Knock Sensor); Engine Camshaft Position Sensor; Crankshaft Sensor

- Replaces: 12555566

- Item Weight: 0.40 Pounds

- Item Dimensions: 3.4 x 2.9 x 1.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 12560228

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2003 Chevrolet Corvette Crankshaft Position Sensor

With a comprehensive array of OEM 2003 Chevrolet Corvette Crankshaft Position Sensor, from fuel pumps to door handles, our website is a one-stop-shop for your needs. All our genuine 2003 Chevrolet Corvette Crankshaft Position Sensor are backed by the manufacturer's warranty and are offered at competitive prices in the market. Rest assured, you can shop with complete confidence.

2003 Chevrolet Corvette Crankshaft Position Sensor Parts and Q&A

- Q: How to service and repair the Crankshaft Position Sensor on 2003 Chevrolet Corvette?A: Start Crankshaft Position Sensor servicing and repairing by installing a scan tool then monitoring the powertrain control module for detection of dtcs. Service procedures should begin with checking dtc p1336 while ignoring all other present dtcs. Begin the crankshaft position (CKP) variation learn procedure through the scan tool by performing vehicle acceleration to maximum throttle position followed by throttle release then observing fuel shutdown conditions. You must keep the engine rpm value within its calibrator specifications and remove throttle pressure straight away if the rpm exceeds limits. Start by blocking the front wheels then engage the parking brake without using the Brake Pedal. Next cycle the ignition from off to on and maintain brake pressure before starting the engine at idle position with a/c turned off. With the vehicle in park or neutral position the scan tool performs comprehensive checks on essential signals that guarantee the procedure meets all requirements. Through the system there are three key components with ect and cmp and ckp sensors that need to be active simultaneously. The procedure demands engine idling duration until the engine reaches proper temperature if the water in the ect remains cool. Begin the ckp system variation learn procedure through the scan tool by achieving wide-open throttle speeds. Engine control returns to the operator when the deceleration starts through immediate throttle release allowing the engine to respond to throttle changes after the learn procedure finishes. Let go of the throttle when the fuel cut-off happens and the scan tool will generate learn status information. Learned this ignition. The ckp variation learn procedure finishes if the scan tool shows dtc p1336 passed its process. Review dtc p1336 when the scan tool shows a diagnostic failure or indicates a failed learn operation. Visit the diagnostic trouble code (DTC) list then review the applicable dtc instructions when dealing with other dtcs. After completing a successful learn procedure users should turn off the ignition for a period of 30 seconds.