ChevyParts

My Garage

My Account

Cart

OEM GMC Savana 3500 Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Brake Discs found

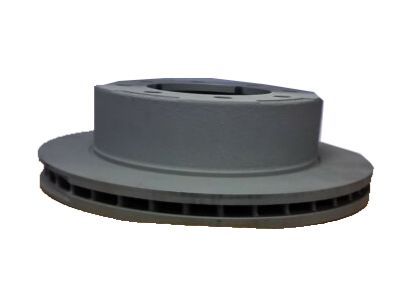

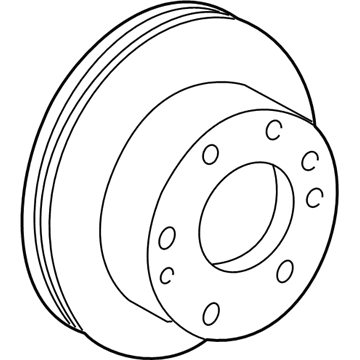

GMC Savana 3500 Rotor Part Number: 15712803

$170.40 MSRP: $325.78You Save: $155.38 (48%)Ships in 1-2 Business Days

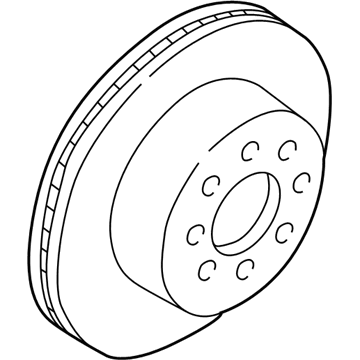

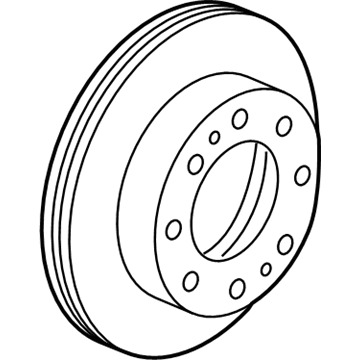

GMC Savana 3500 Rotor Part Number: 15712801

$96.36 MSRP: $180.93You Save: $84.57 (47%)

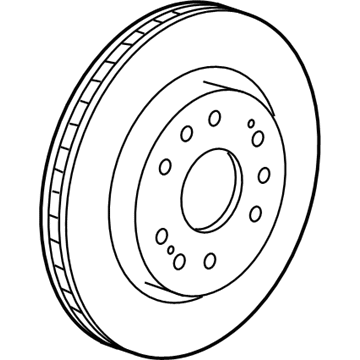

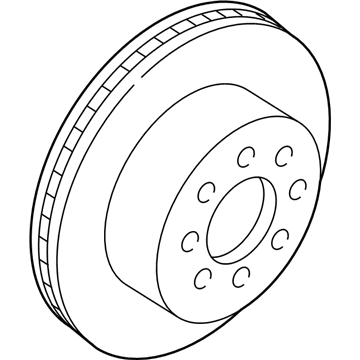

GMC Savana 3500 Rotor, Front Part Number: 22950036

$121.44 MSRP: $235.71You Save: $114.27 (49%)Ships in 1-3 Business Days

GMC Savana 3500 Rotor, Front Part Number: 19210603

$94.27 MSRP: $182.96You Save: $88.69 (49%)Ships in 1-2 Business Days

GMC Savana 3500 Rotor, Front Part Number: 15942198

$192.78 MSRP: $374.16You Save: $181.38 (49%)Ships in 1-2 Business Days

GMC Savana 3500 Rotor, Rear Part Number: 15127537

$134.88 MSRP: $264.04You Save: $129.16 (49%)Ships in 1-2 Business DaysGMC Savana 3500 Rotor, Rear Part Number: 84450466

$109.62 MSRP: $211.47You Save: $101.85 (49%)GMC Savana 3500 Rotor, Front Part Number: 84587921

$136.48 MSRP: $264.90You Save: $128.42 (49%)Ships in 1-2 Business Days

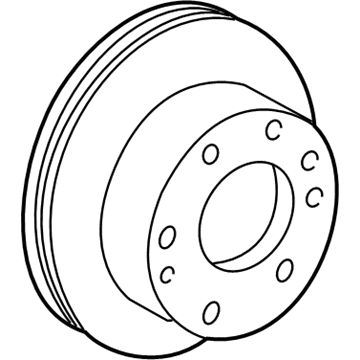

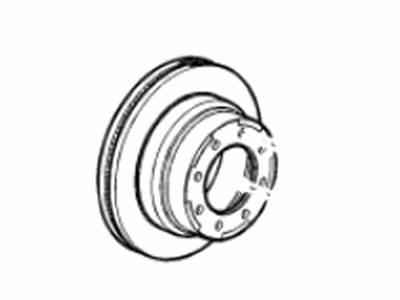

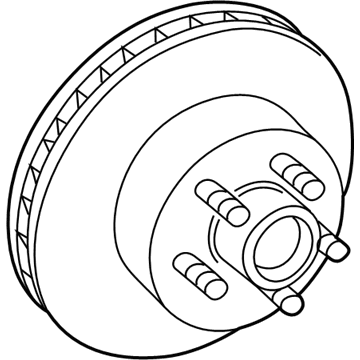

GMC Savana 3500 Hub & Rotor, Front Part Number: 19202727

GMC Savana 3500 Brake Disc

Want to cut long-term maintenance and repair costs? Choose OEM Brake Disc. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine GMC Savana 3500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM GMC Savana 3500 Brake Disc includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

GMC Savana 3500 Brake Disc Parts and Q&A

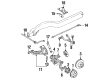

- Q: How to Service and Repair Brake Discs on GMC Savana 3500?A:To clean the brake rotors, and repair, one should start using the Hub Cleaning Kit (J 42450-A) to clean the rust and any foreign items from the mating surface of rotor and flange as there is a high likelihood of obtaining increased lateral runout and break pulsation failure to do so. Next,check the smallest dimension of the brake rotor when using a micrometer; The replacement of its rotor is not allowed; if its size is not within the minimum thickness, the rotor should not be refinished. Instead, it should be replaced. If refinishing is required due to severe scoring, brake pulsation or corrosion below the braking surface, use the Rotor Resurfacing Kit (J 41013) like step by step to clean the rust off the rotor brake flange before you proceed to the machining process according to the break lathe manufacturer's operational instructions on it. After machining, you should produce a non-directional braking surface using a 120-grit aluminium oxide sandpaper and a non directional rotor finisher if applicable. Lastly, clean the braking surfaces with either an GM P/N 12377981 (or equivalent) brake parts cleaner, and consider that, improper wheel nut tightening can cause brake pulsation and rotor damage, so ensure to follow even tighten the wheel nuts using the proper torque specification.

- Q: How to Replace the Front Brake Disc (JH6, JH9) on GMC Savana 3500?A:Use jack and supports to lift the vehicle and uncover the wheel components first before replacing the front Brake Disc (JH6, JH9). Drive a screwdriver through the Brake Disc vanes to stop the disc spinning before removing the hub extension but retaining its marks to the hub. Install aawl to separate the bolts from the hub extension bolts. You can use a non-metallic mallet in a tapping motion to loosen the hub extension where needed. After marking the hub-disc position attach a c-clamp over the caliper to force pistons in before taking off the clamp. Wedge the brake caliper in place using mechanics wire to prevent brake fluid tube harm from accidental damage. Use mechanics wire to sustain the brake caliper assembly as you disconnect its bolts from the caliper bracket and remove it along with the bracket from the wheel assembly. Before pulling off the disc use an oil penetrant to clean surfaces and apply force through two bolts sized m10 x 1.5 to push the disc away from the hub when the disc retaining washers prove difficult to remove. Clean all rust from the hub flange area using j-42450-a. Also remove debris from both contact surfaces. Place the disc back in its proper position and then add the caliper and its support hardware. Clean the caliper bracket bolts from old adhesive then treat their threads with threadlocker part number gm 12345493 (Canadian 10953488). Apply threadlocker to two-thirds of the bolt and allow it to set for 10 minutes before assembly. Safely add the front wheel hub extension if equipped. Then secure all caliper bracket bolts at 300 nm (221 lb ft) prior to installing the wheel hub extension. Put on the tire and wheel components before you apply the brake pedal at one-third of its range until the pedal pressure achieves solidity in multiple instances. After filling the master cylinder with new brake fluid, you should let the pad and disc pairing form a smooth surface by operating the brakes.