ChevyParts

My Garage

My Account

Cart

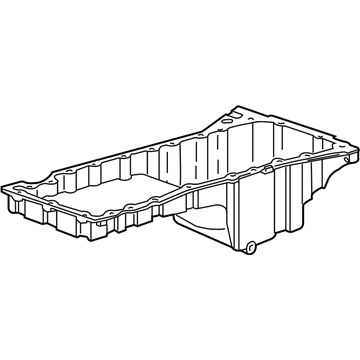

OEM GMC Oil Pan

Oil Drain Pan- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

102 Oil Pans found

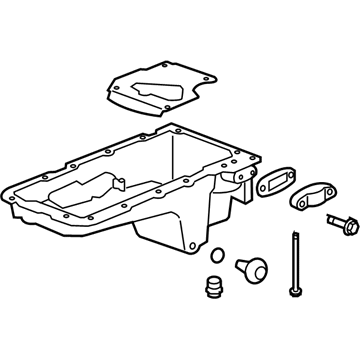

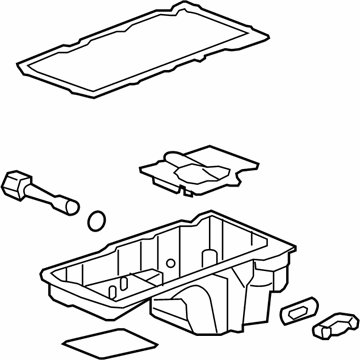

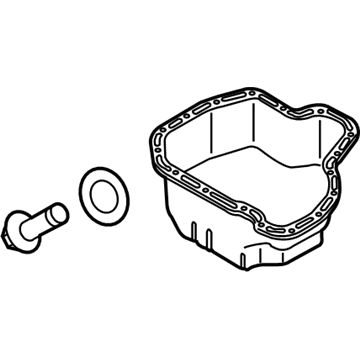

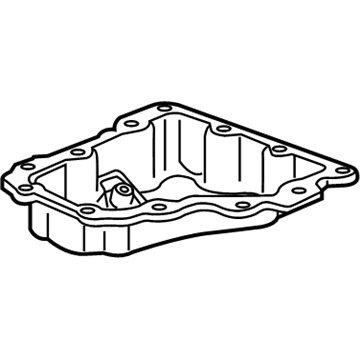

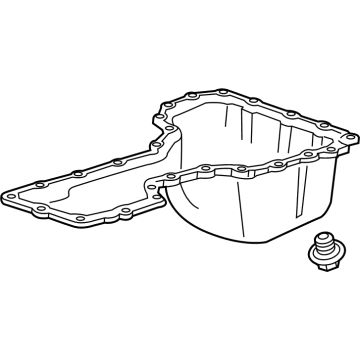

GMC Oil Pan Part Number: 12624621

$166.08 MSRP: $273.58You Save: $107.50 (40%)Product Specifications- Other Name: Pan, Engine Oil

- Replaces: 12614821

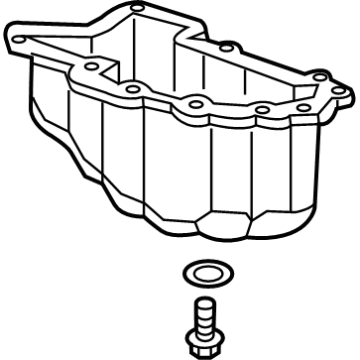

GMC Oil Pan Part Number: 12628375

$98.32 MSRP: $161.91You Save: $63.59 (40%)Product Specifications- Other Name: Pan, Engine Oil; Lower Oil Pan

- Position: Lower

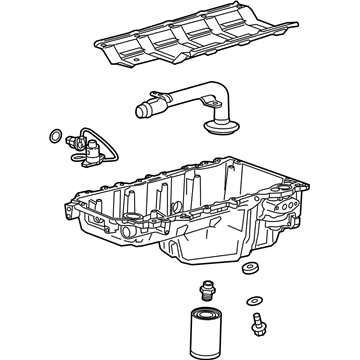

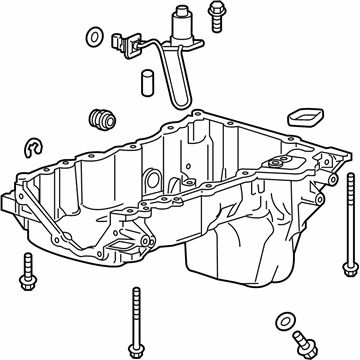

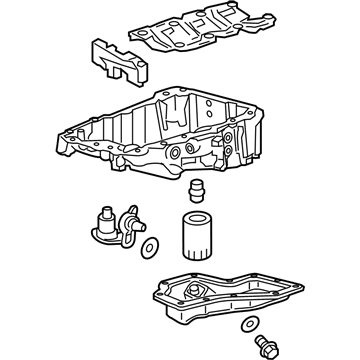

GMC Oil Pan Part Number: 12689456

$193.16 MSRP: $318.19You Save: $125.03 (40%)Product Specifications- Other Name: Pan, Engine Oil

- Replaced by: 12708453

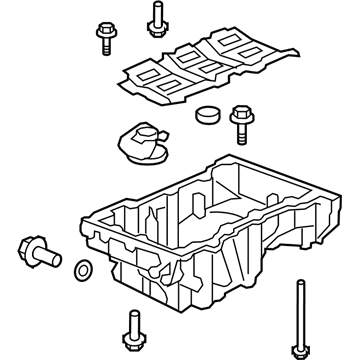

GMC Oil Pan Part Number: 12600497

$225.86 MSRP: $352.23You Save: $126.37 (36%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pan, Engine Oil

- Replaces: 12580241

GMC Oil Pan Part Number: 12684605

$201.24 MSRP: $331.50You Save: $130.26 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pan, Engine Oil; Upper Oil Pan

- Replaces: 12659685, 12619977, 12659831, 12666995, 12707241, 12668476

GMC Oil Pan Part Number: 12619011

$139.55 MSRP: $219.58You Save: $80.03 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pan, Engine Oil

GMC Oil Pan Part Number: 25202730

$99.79 MSRP: $163.31You Save: $63.52 (39%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pan, Engine Oil

- Replaces: 12673396, 12676337, 12689941, 12658228, 12677770, 12688112, 12692504

GMC Oil Pan Part Number: 12669869

$95.80 MSRP: $163.08You Save: $67.28 (42%)Product Specifications- Other Name: Pan, Engine Oil; Lower Oil Pan

- Replaces: 12650979, 12627247

GMC Oil Pan Part Number: 12719108

$162.20 MSRP: $257.47You Save: $95.27 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pan, Engine Oil; Upper Oil Pan

- Replaced by: 12735951

GMC Oil Pan Part Number: 12666372

$219.77 MSRP: $348.80You Save: $129.03 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pan, Engine Oil

GMC Oil Pan Part Number: 12613437

$318.00 MSRP: $523.85You Save: $205.85 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pan, Engine Oil

- Replaces: 12579723, 12624620

GMC Oil Pan Part Number: 28289985

$115.52 MSRP: $183.36You Save: $67.84 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Upper Oil Pan; Pan, Engine Oil

- Replaces: 25202733, 25201776, 12692501, 12692498

GMC Oil Pan Part Number: 12650637

$20.37 MSRP: $32.31You Save: $11.94 (37%)Product Specifications- Other Name: Pan, Engine Oil; Lower Oil Pan

- Position: Lower

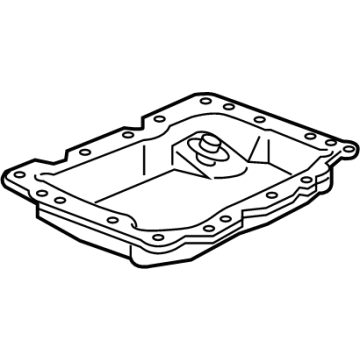

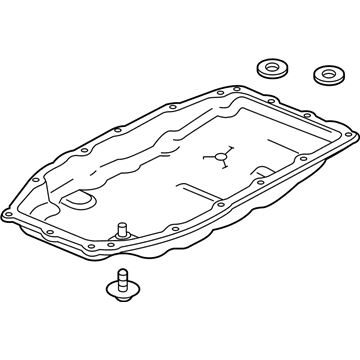

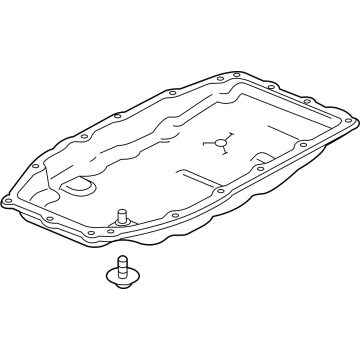

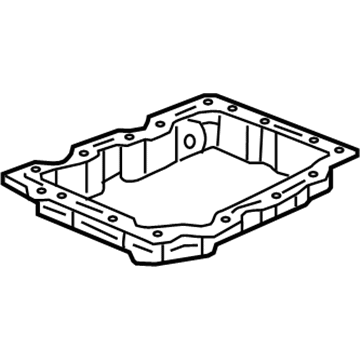

GMC Oil Pan Part Number: 24045038

$43.97 MSRP: $68.88You Save: $24.91 (37%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pan Assembly-Automatic Transmission Fluid; Transmission Pan; Pan, Transmission Oil Pan

- Replaces: 24288996, 24274735, 24278775, 24291926, 24279518

GMC Oil Pan Part Number: 12716560

$175.30 MSRP: $288.71You Save: $113.41 (40%)Product Specifications- Other Name: Pan, Engine Oil; Upper Oil Pan

- Replaced by: 12740763

- Replaces: 12711492, 12679232, 12702893, 12688958, 12671427

GMC Oil Pan Part Number: 12725600

$73.76 MSRP: $126.65You Save: $52.89 (42%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pan, Engine Oil; Lower Oil Pan

- Replaces: 12675087

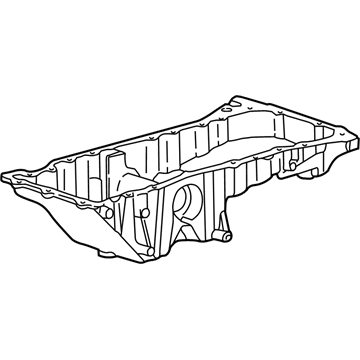

GMC Oil Pan Part Number: 24045041

$37.08 MSRP: $61.09You Save: $24.01 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pan Assembly-Automatic Transmission Fluid; Transmission Pan; Pan, Transmission Oil Pan

GMC Lower Oil Pan Part Number: 12673401

$23.23 MSRP: $36.86You Save: $13.63 (37%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pan, Engine Oil; Oil Pan

- Position: Lower

GMC Oil Pan Part Number: 12640745

$175.66 MSRP: $276.39You Save: $100.73 (37%)Product Specifications- Other Name: Pan, Engine Oil

- Replaces: 12628772

GMC Oil Pan Part Number: 12584321

$221.43 MSRP: $348.26You Save: $126.83 (37%)Product Specifications- Other Name: Pan, Engine Oil; Engine Oil Pan

| Page 1 of 6 |Next >

1-20 of 102 Results

GMC Oil Pan

Choose OEM Oil Pan, you're making the optimal decision for superior quality and perfect performance. You can feel confident because each component goes through stringent quality checks. Every part is carefully built to comply with GMC's factory specifications. You'll enjoy a smooth, worry-free installation that fits just right. At ChevyPartsDeal.com, you'll find it easy to get top-quality OEM GMC Oil Pan. You can shop at highly competitive prices and protect your budget. All our genuine GMC parts include a dependable manufacturer's warranty. You'll also appreciate our straightforward return policy and swift delivery services for extra convenience.

GMC Oil Pan Parts and Q&A

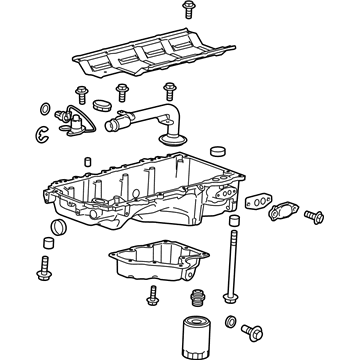

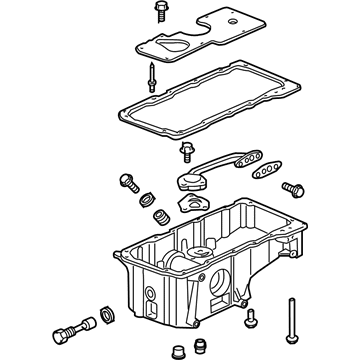

- Q: How to replace the oil pan on GMC Acadia?A:Begin by disconnecting the negative cable of the battery before raising and supporting the vehicle. First remove engine oil drain as well as the Oil Filter before disconnecting the exhaust flexible pipe and the air conditioning (A/C) compressor. The first step requires you to remove Oil Pan bolts before taking out the Oil Pan while preparing both the Oil Pan and engine block gasket surface for cleaning. Install the 8 mm guides using the en 46109 guide pin set (EN 46109) through the center Oil Pan rail bolt holes situated in each engine block side. Use gm p/n 12378521 (Canadian P/N 88901148) or equivalent rtv sealant to create a 3 mm bead on the block pan rail along with the crankshaft rear oil seal housing, after which you should put the Oil Pan onto the block and take out your screw guides. Install the Oil Pan bolts loosely before tightening them accordance with the designated sequence that includes 8 mm bolts (1-11) at 23 n.m (17 lb ft) and 6 mm bolts (12, 13) at 10 n.m (89 lb in). Fasten the 8 mm bolts (1-11) to 23 n.m (17 lb ft) and fasten the 6 mm bolts (12, 13) to 10 n.m (89 lb in). Lower the vehicle and reconnect the battery negative cable before refilling engine oil. After that reinstall the A/C Compressor together with exhaust flexible pipe. Use the j 39505 torque wrench adapter (J 39505) whenever required to complete the tightening operations.

- Q: How to replace the oil pan on 4WD on GMC Sierra 1500?A:Raising and supporting the vehicle should be the first step before replacing its Oil Pan on vehicles with 4wd capabilities. When working on 1500 series vehicles operators should unbolt the skid plate bolts together with the optional skid plate. On 2500 series vehicles, start by loosening the two rear Oil Pan skid plate bolts then remove the two front bolts alongside the skid plate if your vehicle has one. Start by removing the front differential carrier followed by unbolted steering rack installation before hanging it downward. Position a proper drain pan beneath the Oil Pan Drain Plug before you remove it (430) to allow complete oil drainage before tightening the Drain Plug into place. Set a drain pan directly under the Oil Filter before you remove the filter (437) to allow the oil to drain completely while you tighten the Oil Filter until it becomes snug. Detach right and left side transmission cover bolts before removing the cover and crossbar bolts/nuts and crossbar for both 1500 and 2500 series models. Vehicles with 4l60-e/4l70-e automatic transmission require bolt removal from the two lower transmission mounting points. For 4l80-e, remove the 2 lower transmission bolts; 4l80-e requires removal of two lower transmission bolts and 6l80-e demands removal of lower left transmission bolt along with lower right transmission stud. You need to disconnect the engine harness electrical connector at the oil level sensor point while removing the engine harness clip from the transmission oil cooler line bracket and removing the battery cable channel bolt. Insert the Oil Pan tab channel pin into position before removing oil cooler lines from the clip according to transmission type specification. Begin by removing the clip bolt from the transmission oil cooler line on the Oil Pan before taking out the bolts securing the Oil Pan then finally removing the pan itself. You must drill out existing Oil Pan Gasket rivets before removing the gasket when keeping the Oil Pan for use. Toss both the rivets and gasket into the trash. During installation users must place a new Oil Pan Gasket onto the Oil Pan. Users should then add sealant forming a 5 mm (0.20 in) bead that extends 20 mm (0.80 in) along the tabs of the front and rear cover gaskets protruding into the Oil Pan surface of the engine block. Put one Oil Pan bolt through its hole until it reaches the gasket then place the Oil Pan in position while adding remaining Oil Pan bolts before tightening those bolts to a secure fit. Position the oil cooler bracket first and install lower right transmission studs together with lower left transmission bolts until they are hand tight. The appropriate lower transmission bolts need to be installed until they reach their initial tightness for both 4l80-e and 4l60-e/4l70-e transmissions. Tighten all Oil Pan bolts and pan-to-front cover bolts to 25 nm (18 lb ft) torque and Oil Pan-to-rear cover bolts to 12 nm (106 lb in) torque. Additionally, install and torque transmission bolts/stud to 50 nm (37 lb ft). Mount the transmission oil cooler line clip then bolt it to the Oil Pan using a torque of 9 nm (80 lb in). First bolt the oil cooler lines to the clip (as applicable) then position the channel and slide the channel pin into the Oil Pan tab before installing the battery cable channel bolt and tightening it to 12 nm (106 lb in). After connecting the engine harness electrical connector to the oil level sensor route the engine harness clip toward the transmission oil cooler line bracket. Maintenance personnel must remove any existing adhesive from 1500 and 2500 series applications. They must wash the bolt threads with denatured alcohol before applying threadlock gm p/n 12345493 (or Canadian P/N 10953488) or equivalent to the bolt threads. For vehicles in the 2500 series tighten the crossbar bolts/nuts to 120 nm (89 lb ft) while vehicles in the 1500 series require a torque of 100 nm (74 lb ft). Before fastening either bolt you must torque the left side one to 12 nm (106 lb in) followed by torquing the right side one to 12 nm (106 lb in). Before tightening the Oil Filter,get new filter ready and apply clean oil around the seal. Tighten the filter to 30 nm (22 lb ft). After securing the Oil Pan Drain Plug (430) with a torque of 25 nm (18 lb ft) reposition the front differential carrier before raising the steering rack into position and tightening its left side bolts to 200 nm (148 lb ft) and the right side bolts to 100 nm (74 lb ft). Installation of Oil Pan skid plate should begin with tightening the rear Oil Pan skid plate bolts on 2500 series vehicles followed by front bolt installation if vehicle has this equipment, torque all bolts to 28 nm (21 lb ft). Install the Oil Pan skid plate for 1500 series vehicles when equipped with it and torque the bolts to 28 nm (21 lb ft). After dropping the vehicle you should start the motor and fill it with brand-new engine oil before checking for leaks.

Related GMC Parts

Browse GMC Oil Pan by Models

Acadia Sierra 1500 Yukon Canyon Sierra 2500 HD Terrain Envoy Sonoma Typhoon Syclone Caballero C1500 Envoy XL Envoy XUV Jimmy K1500 S15 S15 Jimmy Safari Savana 2500 Savana 3500 Sierra 2500 Sierra 3500 Yukon XL Acadia Limited C2500 C3500 G2500 K2500 K3500 P3500 Savana 1500 Yukon XL 1500 C1500 Suburban C2500 Suburban G1500 G3500 K1500 Suburban K2500 Suburban P2500 R1500 R1500 Suburban R2500 R2500 Suburban R3500 Sierra 1500 Classic Sierra 1500 HD Sierra 1500 HD Classic Sierra 2500 HD Classic Sierra 3500 Classic Sierra 3500 HD V1500 V1500 Suburban V2500 V2500 Suburban V3500 Yukon XL 2500