ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Venture Fuel Rail

Engine Fuel Rail- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Fuel Rails found

Chevrolet Venture Fuel Rail Part Number: 17113256

$113.11 MSRP: $229.18You Save: $116.07 (51%)Ships in 1-2 Business DaysChevrolet Venture Fuel Rail Part Number: 17113608

$119.91 MSRP: $225.16You Save: $105.25 (47%)Ships in 1-2 Business DaysChevrolet Venture Fuel Rail Part Number: 17113607

Chevrolet Venture Fuel Rail Part Number: 17113268

Chevrolet Venture Fuel Rail

Want to cut long-term maintenance and repair costs? Choose OEM Fuel Rail. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Venture parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Venture Fuel Rail includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Venture Fuel Rail Parts and Q&A

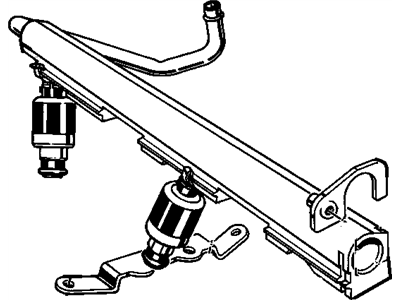

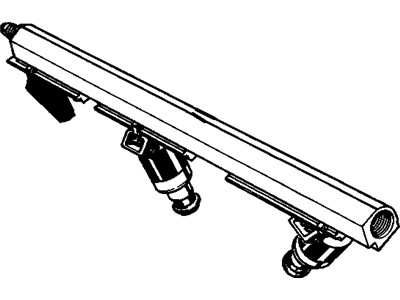

- Q: How to replace the fuel rail assembly on Chevrolet Venture?A:Focus on reading the eight-digit identification number that marks the left-hand Fuel Rail supplying fuel to even cylinders 2, 4 and 6 as your first step in Fuel Rail assembly replacement. Correct o-ring installation requires placement of the black one on top while the brown one should go below because both rings have different materials although they have matching dimensions. The holes in the fuel system need plugging along with fittings that seal off the passages during maintenance procedures. The first step requires draining fuel system pressure before disconnecting the upper Intake Manifold. Cut the pipeline that delivers engine fuel at the Fuel Rail before removing the pipeline that returns engine fuel to the Fuel Pressure Regulator and dispose of all present o-rings in both lines. After pulling up the lock release and pressing the lock tab down disconnect both the Fuel Injector harness electrical connector and the individual connectors that secure the fuel injectors to their places. Detach the injector electrical harness from the Fuel Rail before disconnection of the coolant temperature sensor electrical connector. Proceed to uninstall the Fuel Rail retaining bolts while simultaneously removing the Fuel Rail assembly before extracting the o-ring seal from each injector at their spray tip end. Install the new Fuel Rail assembly by first tilting it before inserting the injectors before securing the attaching bolts and tightening them to 10 n.m (89 lb in). Connect the coolant temperature sensor electrical connector while safely installing the Fuel Rail injector electrical harness followed by relevant connector plug-ins that lock securely. The main injector harness electrical connector needs to be reconnected after installing new o-rings onto both the fuel feed pipe and fuel return pipe. The fuel feed pipe should be connected at the Fuel Rail where the nut needs to be tightened to 17 n.m (13 lb ft). The fuel return pipe needs to be connected to the Fuel Pressure Regulator while torquing the nut to 17 n.m (13 lb ft). The procedure concludes with reconnecting the negative Battery Cable. The inspection process includes testing fuel leaks by flipping the ignition twice for two seconds followed by ten seconds off before turning it back on prior to reinstalling the upper Intake Manifold.

- Q: How to service the fuel rail on Chevrolet Venture?A:Service of the Fuel Rail starts by looking at the left-hand Fuel Rail which serves even cylinders 2, 4, and 6. The Fuel Rail carries an eight-digit identification number stamped on the left side. Installation of fuel injector o-rings requires correct placement where black o-rings should be at the top position while brown o-rings go into the lower position. Service procedures require that fuel passages remain free from dirt and contaminants by installing fitting caps together with plastic plugs into the holes. You must first reduce pressure from the fuel system before removing the upper Intake Manifold. Disconnect the fuel pipe that supplies engine fuel to the rail while also detaching the fuel return pipe connected to the Fuel Pressure Regulator. First disconnect the main injector harness electrical connector along with pulling up the lock release then depressing the lock tab before lifting the connector off the injector. At the same time discard the fuel feed pipe and fuel return pipe o-rings. First tighten the Fuel Rail assembly by removing its retaining bolts but before doing so you must disconnect the coolant temperature sensor electrical connector and injector electrical harness from the Fuel Rail along with removing the Fuel Rail retaining bolts. Detach the injector o-ring seal that exists at the spray tip end of each injector. Follow this procedure when installing the Fuel Rail assembly by tilting it first before installing the injectors then secure with Fuel Rail attaching bolts that need to be tightened to 10 n.m (7 lb ft). Synchronize the Fuel Rail by connecting the coolant temperature sensor electrical connector followed by installing the injector electrical harness and finalizing with attaching the injector connectors and pushing slide locks into their position. After installing new o-rings on the fuel feed pipe and fuel return pipe, the main injector harness electrical connector should be connected while the fuel feed pipe at the Fuel Rail needs tightening to 17 n.m (13 lb ft). Attach the fuel feed pipe to the Fuel Pressure Regulator while torquing its nut to 17 n.m (13 lb ft). Then reposition the upper Intake Manifold. The inspection for fuel leaks should begin with turning the ignition on for 2 seconds followed by a 10-second off period then a reengage of the on state to check if any leaks occur.