ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Tahoe Fuel Injector

Gas Injector- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

27 Fuel Injectors found

Chevrolet Tahoe Injector Part Number: 12609749

$73.20 MSRP: $148.68You Save: $75.48 (51%)Ships in 1-2 Business Days

Chevrolet Tahoe Injector Part Number: 19420316

$68.70 MSRP: $139.52You Save: $70.82 (51%)Ships in 1 Business Day

Chevrolet Tahoe Injector Part Number: 12710481

$69.60 MSRP: $141.40You Save: $71.80 (51%)

Chevrolet Tahoe Injector Part Number: 12594512

$69.70 MSRP: $141.56You Save: $71.86 (51%)Ships in 1-2 Business Days

Chevrolet Tahoe Injector Part Number: 12580426

$107.23 MSRP: $217.78You Save: $110.55 (51%)Ships in 1-2 Business DaysChevrolet Tahoe Injector Part Number: 12690934

$38.83 MSRP: $109.30You Save: $70.47 (65%)Ships in 1-2 Business DaysChevrolet Tahoe Injector Part Number: 97780474

$486.29 MSRP: $963.93You Save: $477.64 (50%)Ships in 1-3 Business DaysChevrolet Tahoe Injector Part Number: 97729095

$274.91 MSRP: $543.11You Save: $268.20 (50%)Ships in 1-3 Business DaysChevrolet Tahoe Injector Part Number: 12613411

$83.42 MSRP: $172.82You Save: $89.40 (52%)Ships in 1-2 Business DaysChevrolet Tahoe Injector Part Number: 55506244

$189.39 MSRP: $384.68You Save: $195.29 (51%)Ships in 1-3 Business DaysChevrolet Tahoe Injector Part Number: 12732623

$60.77 MSRP: $108.52You Save: $47.75 (44%)Chevrolet Tahoe Injector Part Number: 17113553

$73.17 MSRP: $228.30You Save: $155.13 (68%)Ships in 1-2 Business Days

Chevrolet Tahoe Injection Nozzle Part Number: 10233973

Chevrolet Tahoe Injector Part Number: 12684125

Chevrolet Tahoe Injector Part Number: 19110538

$224.13 MSRP: $402.02You Save: $177.89 (45%)Chevrolet Tahoe Injector Part Number: 97780144

$531.79 MSRP: $837.17You Save: $305.38 (37%)Chevrolet Tahoe Injector Part Number: 17091432

Chevrolet Tahoe Injector Part Number: 17113582

Chevrolet Tahoe Fuel Rail Part Number: 52371460

Chevrolet Tahoe Throttle Body Part Number: 17112913

| Page 1 of 2 |Next >

1-20 of 27 Results

Chevrolet Tahoe Fuel Injector

Want to cut long-term maintenance and repair costs? Choose OEM Fuel Injector. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Tahoe parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Tahoe Fuel Injector includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

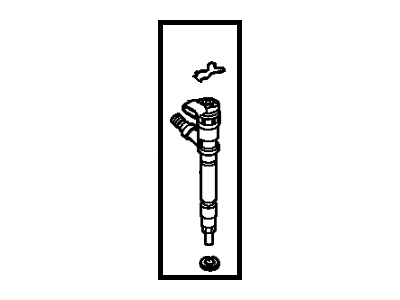

The Fuel Injector used in the Chevrolet Tahoe automobiles is an important element that directly injects fuel into the engine cylinder depending on the existing load on the engine. This one is an electronic system that is managed by the engine control unit and replaces the earlier carburetor system to contribute to improved efficiency and vigor of the engine. Defective fuel injectors can cause an automobile to stall, run roughly, develop less power, and obtain poor fuel economy; this may harm catalytic converter and oxygen sensor. To avoid such problems, it is advisable to change bad fuel injector as soon as they develop problems. In Chevrolet Tahoe, there are changes in the type of fuel injector containing two main types that are the direct and Indirect fuel injector with its own advantages in the way of sending the injection of the fuel to the engine.

Chevrolet Tahoe Fuel Injector Parts and Q&A

- Q: How to replace the fuel injectors on Chevrolet Tahoe?A:The Fuel Injector replacement process starts by properly removing the air cleaner outlet duct then using ch-48027 or without it when relieving fuel system pressure. You need to disconnect ranges of engine wiring harness electrical connectors off components including evap purge solenoid, generator, MAP Sensor and Ignition Coil and fuel injectors while you need to mark the connectors for correct future placement. The engine wiring harness clips and negative charge lead need to be detached from the right cylinder head position. First disconnect the quick connect fitting that feeds fuel to the chassis from its location on the Fuel Rail and also release the quick connect fittings at the intake manifold for the evap tube then at the evap canister purge solenoid. After unhinging the retainer holding the evap canister purge solenoid to the Fuel Rail you can extract the Fuel Rail assembly bolts while lifting the rail assembly carefully to prevent damage to the electrical connector terminals and spray tips. Begin the procedure by cleaning the Fuel Rail followed by removing the Fuel Injector retainers and lift out the injectors after disposing the old o-ring seals. Start by applying engine oil to new o-ring seals before installing them to injectors followed by inserting the injectors into the Fuel Rail. Position the Fuel Rail properly onto the intake manifold while keeping the retainers in place. Push down on the rail to achieve complete seating. After fitting the Fuel Rail bolts at 10 nm (89 lb in) tightness connect the evap tube and purge solenoid as well as the chassis fuel feed pipe quick connect fitting. Next position the pcv hose then gather the engine wiring harness before fixing it into position with its clips. The negative Battery Cable needs to be reconnected when all electrical connectors are tightened in place and engine wiring harness brackets receive a 5 nm (44 lb in) torque setting. Complete the check for leaks by turning the ignition on before reinstalling the air cleaner outlet duct.

- Q: How to service the fuel injectors on Chevrolet Tahoe?A:Service of fuel injectors begins with removing the Fuel Rail which releases the Fuel Injector retainer clip and finally extracting the Fuel Injector. Toss away both the Fuel Injector retainer clip together with the Fuel Injector O-Ring seals (2, 4). Always obtain fuel injectors that match the specific application requirements before new installation. The fuel injectors display two markings: a part number id together with a four-digit code which declares manufacturing month, day, year and shift. The new Fuel Injector O-Ring seals (2, 4) need engine oil lubrication before being installed onto the Fuel Injector. A new retainer clip should be placed onto the Fuel Injector before inserting the Fuel Injector into the Fuel Rail injector socket with its electrical connector facing outward. The retainer clip should attach to a flange which exists on the Fuel Rail injector socket. Finally, reinstall the Fuel Rail.