ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Express 3500 Distributor

Ignition Distributor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Distributors found

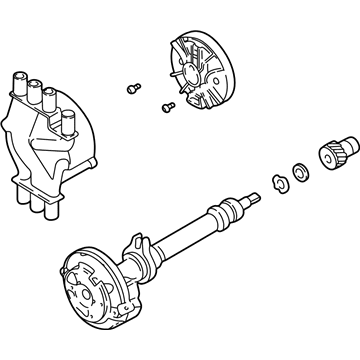

Chevrolet Express 3500 Distributor Assembly Part Number: 19179576

$304.49 MSRP: $554.62You Save: $250.13 (46%)Ships in 1-2 Business Days

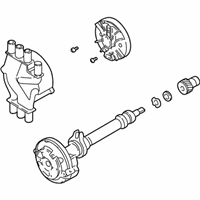

Chevrolet Express 3500 Distributor Assembly Part Number: 12598210

Chevrolet Express 3500 Distributor Assembly Part Number: 94672691

Chevrolet Express 3500 Distributor

Want to cut long-term maintenance and repair costs? Choose OEM Distributor. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Express 3500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Express 3500 Distributor includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Express 3500 Distributor Parts and Q&A

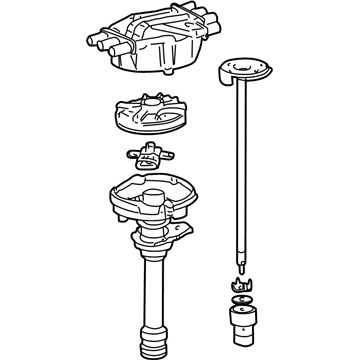

- Q: How to service and repair the distributor on Chevrolet Express 3500?A:Begin Distributor service and repair by turning off ignition first and removing the engine cover. Position marks on the Distributor's driven gear and Distributor shaft and rotor holes to maintain proper installation alignment since improper assembly will prevent engine startup and possibly cause engine harm. When servicing the Distributor start by removing the screws from both the rotor and Distributor before extracting the rotor and keeping note of the reference holes for later installation. The cmp sensor must be removed by aligning its square-cut hole with the vane wheel before discarding the screws which retain the sensor. Check the gear's dimple by the roll pin hole to understand proper installation orientation before putting everything back together. Use a v-block to support the Distributor drive gear before extracting the roll pin with an appropriate punch to remove the driven gear as well as round washer and tang washer and shim washer and old oil seal gasket. Insert the cmp sensor into the housing through its square-cut hole in the vane wheel before tightening new screws to 2.2 n.m (20 lb in). Follow index marks to place rotor correctly before screwing it into position with 1.9 n.m (17 lb in) torque. Position the shim washer onto the Distributor shaft before adding the tang washer and round washer. Then set the driven gear into position according to index marks with the white paint mark matching the pre-drilled indent hole of the gear . The driven gear installation requires careful inspection because the dimple must face the opposite direction from the rotor segment by 180 degrees. Position the Distributor drive gear in a v-block and apply a roll pin by using a punch and striking with a hammer. Secure Distributor Cap screws with 2.4 n.m (21 lb in) torque. Before installation of the Distributor base's mounting flange position the new oil seal gasket underneath. Next install the Distributor followed by electrical connector attachment and completing the spark plug wire connections to the Distributor Cap being mindful to avoid contact between the ignition coil wire and any objects to avoid shorting or grounding. Place the ignition coil wire and position the engine cover into its original place.