ChevyParts

My Garage

My Account

Cart

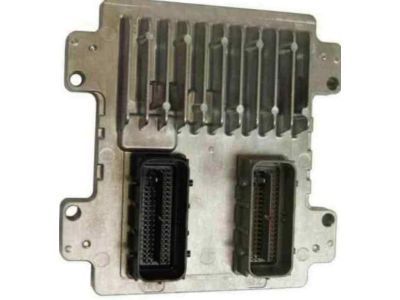

OEM Chevrolet Express 1500 Engine Control Module

Engine Control Computer- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Engine Control Modules found

Chevrolet Express 1500 Knock Sensor Part Number: 12612397

$316.33 MSRP: $642.48You Save: $326.15 (51%)

Chevrolet Express 1500 ECM Part Number: 12635043

$213.69 MSRP: $434.02You Save: $220.33 (51%)Ships in 1-2 Business Days

Chevrolet Express 1500 PCM Part Number: 12633238

$245.01 MSRP: $496.56You Save: $251.55 (51%)Ships in 1-2 Business Days

Chevrolet Express 1500 ECM Part Number: 12625455

$232.61 MSRP: $424.70You Save: $192.09 (46%)Ships in 1-2 Business DaysChevrolet Express 1500 PCM Part Number: 12612384

$261.01 MSRP: $488.26You Save: $227.25 (47%)Ships in 1-2 Business DaysChevrolet Express 1500 ECM Part Number: 12602801

$534.19 MSRP: $962.30You Save: $428.11 (45%)Ships in 1-2 Business Days

Chevrolet Express 1500 Control Module Part Number: 16229684

Chevrolet Express 1500 PCM Part Number: 16244210

Chevrolet Express 1500 PCM Part Number: 12581565

Chevrolet Express 1500 Control Module Part Number: 9366810

$266.44 MSRP: $470.38You Save: $203.94 (44%)Chevrolet Express 1500 PCM Part Number: 16263494

$341.63 MSRP: $610.42You Save: $268.79 (45%)

Chevrolet Express 1500 Engine Control Module

Want to cut long-term maintenance and repair costs? Choose OEM Engine Control Module. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Express 1500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Express 1500 Engine Control Module includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Express 1500 Engine Control Module Parts and Q&A

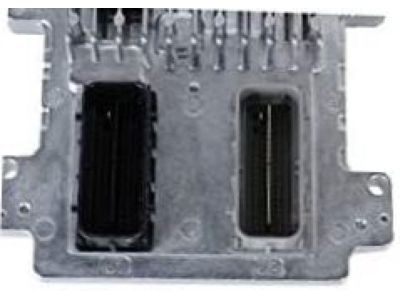

- Q: What does the service of the engine control module (ECM) typically involve on Chevrolet Express 1500?A:Service operations on the powertrain control module (PCM) usually include pcm substitution or eeprom electrical erasable programmable read-only memory programming. Inspection of the pcm happens first to confirm the right part will be used for replacement. Before installation of the new service pcm confirm the diagnosis of the faulty unit then proceed with the replacement. You should switch off the ignition before working with pcm connectors because this prevents internal damage when disconnecting or reconnecting power. The pcm connector should have all debris removed thoroughly and connector gaskets need to be checked for proper installation because these gaskets protect against contaminant entry. Programming of the new pcm forms a necessary step in the replacement process. Your first step should be to use a diagnostic tool for retrieving oil life percentage data since non-programming the replacement module will set engine oil to its maximum value which requires a change at 5,000 km (3,000 mi) from the prior service. Disconnection of both the negative Battery Cable and pcm harness connectors must happen while maintaining no contact with connector pins and soldered components to stop electrostatic discharge (ESD) damage. Before removing the pcm from its mounting tray users should press the spring latch then lift it upwards. After that users should take it out of the engine compartment. Return the pcm to its mounting tray by fastening the spring mechanism before connecting all connectors and tightening the fasteners to 8 n.m (71 lb in). The last step includes reconnecting the negative Battery Cable followed by programming the pcm if it is brand new.