ChevyParts

My Garage

My Account

Cart

OEM Cadillac DeVille Fuel Rail

Engine Fuel Rail- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Fuel Rails found

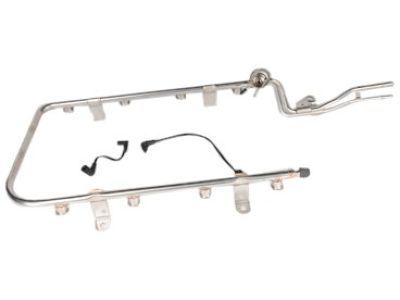

Cadillac DeVille Fuel Rail Part Number: 12499784

Cadillac DeVille Fuel Rail Part Number: 25516337

Cadillac DeVille Fuel Rail Part Number: 17086696

Cadillac DeVille Fuel Rail Part Number: 17113142

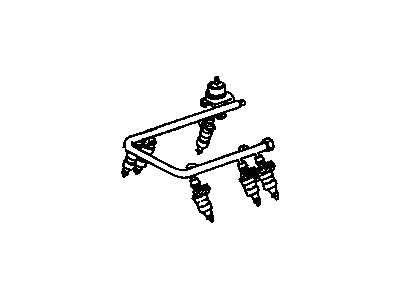

Cadillac DeVille Fuel Rail Part Number: 17105956

Cadillac DeVille Fuel Rail Part Number: 12579067

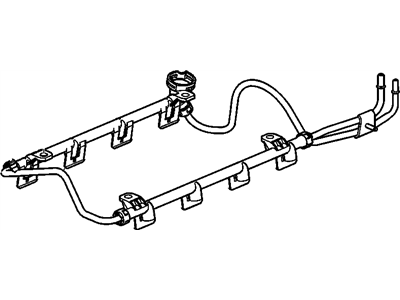

Cadillac DeVille Fuel Rail Part Number: 12499782

Cadillac DeVille Fuel Rail

Want to cut long-term maintenance and repair costs? Choose OEM Fuel Rail. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Cadillac DeVille parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Cadillac DeVille Fuel Rail includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Cadillac DeVille Fuel Rail Parts and Q&A

- Q: How to replace the fuel rail assembly on Cadillac DeVille?A:The first step for Fuel Rail assembly replacement requires drainage of fuel system pressure. When removing the Fuel Rail assembly take necessary precautions to protect injector electrical connector terminals and spray tips since proper support will protect each component from damage. Cover all fittings while you insert plugs into holes for contaminant prevention. The gm x-30a engine cleaner or equivalent spray-based solution should clean the Fuel Rail assembly following label directions without letting it absorb liquid cleaning agents. Disconnect components 2 and 3 that consist of fuel feed and return pipes as well as the pcv air tube, Fuel Pressure Regulator vacuum hose and PCV Valve from the cam cover. First remove the Fuel Rail bracket retainer nut before disconnecting Fuel Injector electrical connectors from each Fuel Injector. Lay the harness to the side and unplug the engine wiring harness from the Fuel Rail studs. Extract the Fuel Rail attaching studs together with the Fuel Rail before lifting off the lower o-ring seals from each injector spray tip end to dispose of them. The replacement process of a Fuel Rail requires complete removal of both fuel injectors and the Fuel Pressure Regulator. The procedure for Fuel Pressure Regulator and Fuel Injector assembly should start with Fuel Pressure Regulator installation followed by Fuel Injector installation. The new injector lower o-ring seals should receive clean engine oil lubrication before installation while keeping the Fuel Rail ports blocked from foreign substances. Begin by installing the Fuel Rail followed by the Fuel Rail attaching studs . Then tighten both pieces to 10 n.m (89 lb in). Connect electrical Fuel Injector connectors to each Fuel Injector followed by installation of a retainer nut onto the Fuel Rail bracket and its tightening to 10 n.m (89 lb in). Afterward, install the PCV Valve at the cam cover, coolant surge tank inlet and pcv air tube. The Fuel Rail receives its Fuel Pressure Regulator vacuum hose together with the feed and return pipes (2, 3) before reconnection of the negative cable and the verification of any fuel leaks through a 2-second ignition on with engine off followed by 10 seconds off and a final 2-second check for leaks with ignition on. Install the Fuel Injector sight shield as the last step.