ChevyParts

My Garage

My Account

Cart

OEM Buick Rendezvous Brake Booster

Brake Power Booster- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Brake Booster found

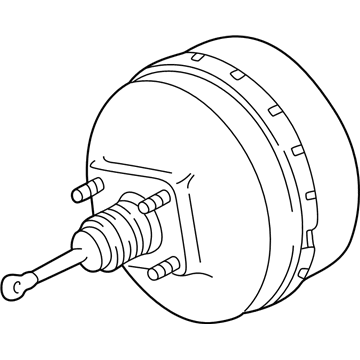

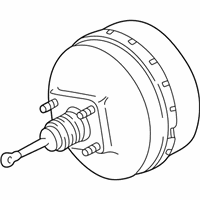

Buick Rendezvous Brake Booster Part Number: 18045787

$323.88 MSRP: $608.23You Save: $284.35 (47%)Ships in 1-2 Business Days

Buick Rendezvous Brake Booster

Want to cut long-term maintenance and repair costs? Choose OEM Brake Booster. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Buick Rendezvous parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Buick Rendezvous Brake Booster includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

The Buick Rendezvous Brake Booster is an important item that contributes huge when it comes to braking system and safety; it is an important part of any Buick Rendezvous model. Intended to lessen the amount of force necessary on the brake pedal, the Brake Booster works with either vacuum or hydraulic pressure to amplify the driver's input so that the experience of driving is smooth and responsive. This feature is even more crucial to the Buick Rendezvous manufactured between 2002 and 2007 because it bridges the luxury and utility standard for a mid-size crossover SUV. This is particularly desirable, because the Brake Booster must be capable to suit the given models of Rendezvous, and adapt to different types of brake system and arrangements. Buick uses the Brake Booster for reliability hence the durability in the application even though brake booster replacements might be required for the vacuum type at times. The Buick Rendezvous Brake Booster positions the car maker differently in the market given the important function it plays in improving safety and comfort for family car travelers. Moreover, the utilization of special features like the models and options of the Buick brand as well as differing types of diaphragms proves Buick's commitment to performance and customerstisfaction again. In conclusion, Buick Rendezvous Brake booster is one of the defining features of the brand that adheres to the concepts of dependability and efficiency on the road, which have ensured that Rendezvous's place in the list of mid size crossover SUVs would remain popular.

Buick Rendezvous Brake Booster Parts and Q&A

- Q: How to replace the Vacuum Brake Booster on a 3.5L engine on Buick Rendezvous?A:Before working on the vacuum Brake Booster you must first relieve fuel line pressure and drain the cooling system on a 3.5l engine. Take off all parts including the Coolant Reservoir, left front belt frame, and powertrain control module housing from the air filter location. Place the pcm aside instead of unplugging its electrical wires and take out the air cleaner plus its duct system. Disconnect fuel lines both behind and within the vapor tube according to metal and plastic connector protocols. Unplug the heater hose from the coolant crosspassage and move it aside to obtain access to brake pipes. Detach fuel lines from the shock tower to reach brake pipes and disconnect the fluid level sensor switch from the Brake Master Cylinder. Take off the master cylinder and abs module after disconnecting the Brake Lines that attach to it. Disconnect the vacuum hose from the valve of the vacuum Brake Booster and put it aside before disassembling the knee bolster. Disconnect the booster push pin parts with its washer from Brake Pedal assembly before pulling out the Brake Booster pushrod. Use a wrench to take off Brake Booster mounting nuts then disconnect the two front Engine Mounts along with their nuts and bolts. Move the engine forward to get to the Brake Booster for uninstallation. Mount the Brake Booster onto the cowl and mounting plate before fastening the Brake Booster assembly nuts to 25 nm (18 ft. Lbs. Torque). First place the master cylinder into position while setting the Brake Booster push rod to the Brake Pedal and maintaining it with both pieces of hardware. Set the stoplamp switch to block brake dragging and lessen parts wear before putting in the knee bolster. Replace the engine back into position and fasten engine mounts with their bolts and nuts. Place the vacuum Brake Booster check valve hose on first, then set the abs module bracket and module together with the Brake Master Cylinder and brake lines. Wire the fluid level sensor on the master cylinder and attach fuel lines to their mounting positions on the shock tower. Also replace the heater hose connector to the coolant crossover pipe. Afterward place back the components in their original positions including the engine compartment air filter assembly and ductwork while reinstalling the pcm housing unit. Fully charge the cooling system and perform brake pressure release to finish the procedure.