ChevyParts

My Garage

My Account

Cart

OEM Buick CV Boot

Axle Boot- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

87 CV Boots found

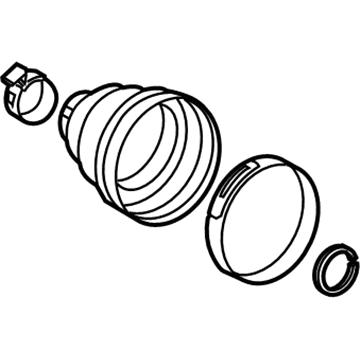

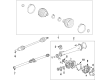

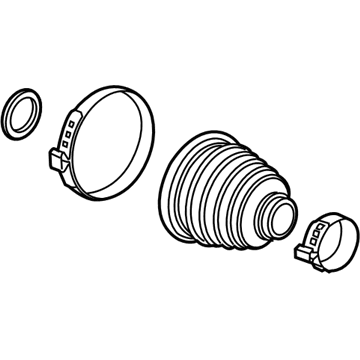

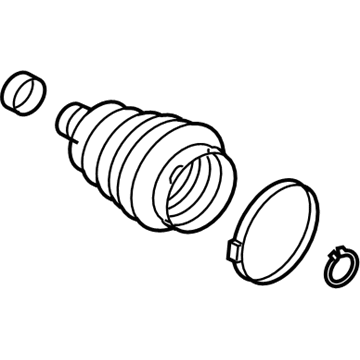

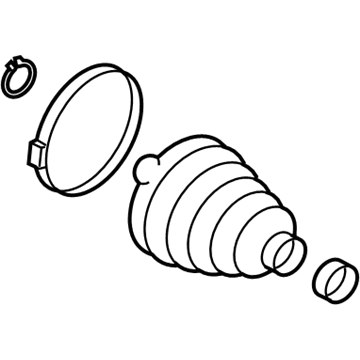

Buick Inner Boot Part Number: 95908486

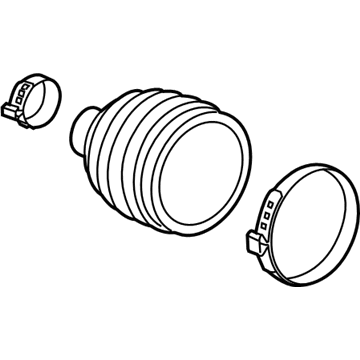

$54.83 MSRP: $90.31You Save: $35.48 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot Kit-Front Wheel Drive Shaft CV Joint Inner; CV Boot; Boot Kit, Rear Axle Universal Joint

- Position: Front Inner

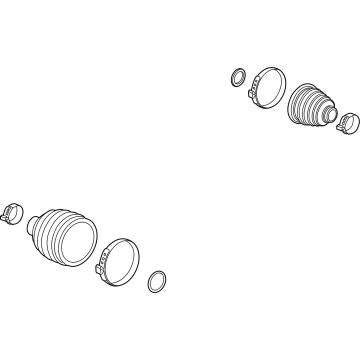

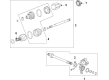

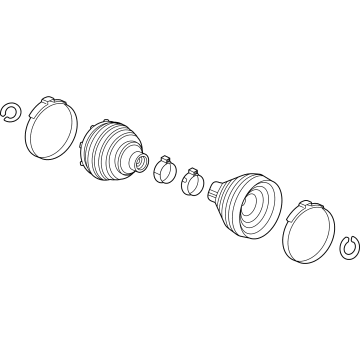

Buick Boot Kit Part Number: 42756982

$39.42 MSRP: $64.93You Save: $25.51 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Boot Kit-Front Wheel Drive Shaft Tri-Pot & CV Joint; CV Boot; Boot Kit, Front Wheel Drive Axle Shaft

- Position: Front

- Replaces: 42721962

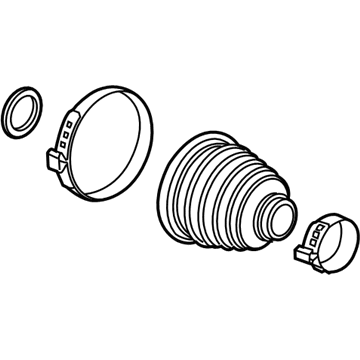

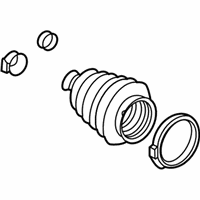

Buick Boot Kit, Rear Passenger Side Part Number: 42722017

$35.75 MSRP: $56.00You Save: $20.25 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Boot Kit-Rear Wheel Drive Shaft CV & Tri-Pot Joint; CV Boot; Boot Kit, Rear Axle Universal Joint

- Position: Rear Passenger Side

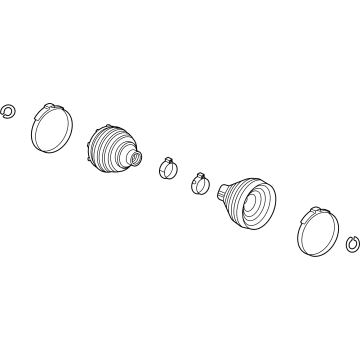

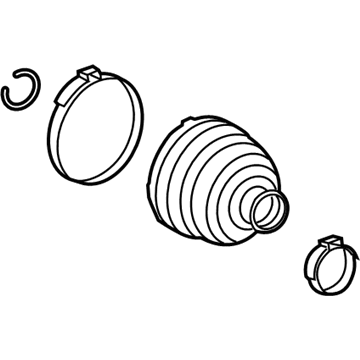

Buick Boot Kit Part Number: 84930204

$69.50 MSRP: $110.35You Save: $40.85 (38%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Boot Kit-Front Wheel Drive Shaft Tri-Pot & CV Joint; CV Boot; Boot Kit, Front Wheel Drive Axle Shaft

- Position: Front

- Replaced by: 85634569

Buick Boot Kit Part Number: 84945203

$72.13 MSRP: $118.82You Save: $46.69 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Boot Kit-Front Wheel Drive Shaft Tri-Pot & CV Joint; CV Boot; Boot Kit, Front Wheel Drive Axle Shaft

- Position: Front

- Replaced by: 86585864

Buick Boot Kit Part Number: 42721984

$38.34 MSRP: $63.15You Save: $24.81 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Boot Kit-Front Wheel Drive Shaft Tri-Pot & CV Joint; CV Boot; Boot Kit, Front Wheel Drive Axle Shaft

- Position: Front

Buick Outer Boot, Front Part Number: 38026971

$86.79 MSRP: $137.80You Save: $51.01 (38%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Boot Kit, Front Wheel Drive Axle Shaft; CV Boot

- Position: Front

Buick Inner CV Joint Boot, Front Part Number: 15855655

$20.23 MSRP: $32.12You Save: $11.89 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot Kit, Front Wheel Drive Axle Shaft; CV Boot; Inner Boot; Boot Kit, Front Axle

- Position: Front

Buick Inner Boot Part Number: 95908489

$41.48 MSRP: $68.32You Save: $26.84 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Boot Kit-Front Wheel Drive Shaft CV Joint Inner; CV Boot; Boot Kit, Front Wheel Drive Axle Shaft

- Position: Front

Buick Inner Boot, Front Part Number: 38026972

$189.41 MSRP: $300.73You Save: $111.32 (38%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Boot Kit, Front Wheel Drive Axle Shaft; CV Boot

- Position: Front

- Replaced by: 84282537

Buick Outer Boot Part Number: 95908464

$49.24 MSRP: $78.18You Save: $28.94 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot Kit, Front Wheel Drive Axle Shaft; CV Boot; Boot Kit, Rear Axle Universal Joint

- Position: Front Outer

Buick Outer Boot, Rear Part Number: 22855573

$84.46 MSRP: $134.08You Save: $49.62 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot Kit-Rear Wheel Drive Shaft CV Joint; CV Boot; Boots; Boot Kit, Rear Axle Universal Joint

- Position: Rear

- Replaces: 19258587

Buick Outer Boot, Front Part Number: 84282541

$42.67 MSRP: $66.82You Save: $24.15 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Boot Kit, Front Wheel Drive Axle Shaft; CV Boot

- Position: Front

Buick Boot Kit, Driver Side Part Number: 42871670

$36.88 MSRP: $58.56You Save: $21.68 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot Kit-Rear Wheel Drive Shaft CV & Tri-Pot Joint; Boot Kit, Rear Axle Universal Joint

- Position: Driver Side

Buick Boot Kit, Rear Driver Side Part Number: 42722013

$40.21 MSRP: $62.98You Save: $22.77 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Boot Kit-Rear Wheel Drive Shaft CV & Tri-Pot Joint; CV Boot; Boot Kit, Rear Axle Universal Joint

- Position: Rear Driver Side

Buick Inner Boot, Front Driver Side Part Number: 84282536

$53.00 MSRP: $83.00You Save: $30.00 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Boot Kit, Front Wheel Drive Axle Shaft; CV Boot

- Position: Front Driver Side

Buick Outer Boot, Rear Part Number: 23218688

$107.12 MSRP: $176.46You Save: $69.34 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Boot Kit-Rear Wheel Drive Shaft CV Joint; CV Boot; Inner Boot; Boots; Boot Kit, Rear Axle Universal Joint

- Position: Rear

Buick Inner Boot, Front Passenger Side Part Number: 84282545

$45.64 MSRP: $71.48You Save: $25.84 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Boot Kit, Front Wheel Drive Axle Shaft; CV Boot

- Position: Front Passenger Side

Buick Inner Boot, Rear Part Number: 15855657

$111.88 MSRP: $175.24You Save: $63.36 (37%)Product Specifications- Other Name: Boot Kit, Rear Axle Universal Joint; CV Boot; Boots

- Position: Rear

Buick Boot Kit, Passenger Side Part Number: 42871671

$35.83 MSRP: $56.13You Save: $20.30 (37%)Product Specifications- Other Name: Boot Kit-Rear Wheel Drive Shaft CV & Tri-Pot Joint; Boot Kit, Rear Axle Universal Joint

- Position: Passenger Side

| Page 1 of 5 |Next >

1-20 of 87 Results

Buick CV Boot

Choose OEM CV Boot, you're making the optimal decision for superior quality and perfect performance. You can feel confident because each component goes through stringent quality checks. Every part is carefully built to comply with Buick's factory specifications. You'll enjoy a smooth, worry-free installation that fits just right. At ChevyPartsDeal.com, you'll find it easy to get top-quality OEM Buick CV Boot. You can shop at highly competitive prices and protect your budget. All our genuine Buick parts include a dependable manufacturer's warranty. You'll also appreciate our straightforward return policy and swift delivery services for extra convenience.

Buick CV Boot Parts and Q&A

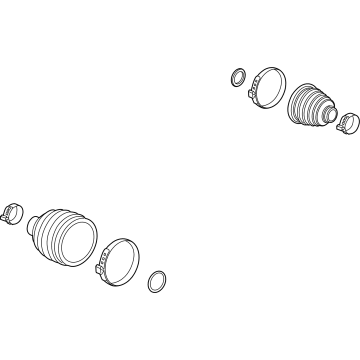

- Q: How to Replace a CV Boot and CV Joint on a Front Wheel Drive Shaft for Outer on Buick Enclave?A:Replacing the front wheel drive shaft outer joint and boot involves removing the wheel drive shaft from the car then installing drive Axle Shaft in a soft jawed vice while being careful not to cut through the inboard or outboard boot as a result will damage sealant surface and cause it to wear out quickly on the part of constant velocity joint. Use a flat-bladed tool to remove boot clamp from constant velocity (cv) joint and the boot , while being careful not to rotate the shaft , remove the boot clamp off the boot and the wheel drive shaft using side cutters. Replace the old boot clamps with a new one. Then, detach the cv joint from the wheel drive shaft, remove the boot from the wheel drive shaft, and also remove a wheeled drive shaft using a block of wood and a hammer. Check the outer cv joints for damages and wear. Position the boot on the wheel drive shaft, with it well seated into the norted wheel drive shaft. Put about half of the lubricant from the service kit into the outboard boot and put the cv joint in the rest of the lubricant. Mount the cv joint on the wheel drive shaft using a block of wood and a hammer, install the boot clamp onto the boot and the wheel drive shaft followed by boot clamp to the boot and cv joint housing. Analyze the location of the boot clamp around the entire circumference of the boot and the measurement of the gap which should not exceed 1.8 mm (0.07 in) for vehicles with x88 and 2.6 mm (0.10 in) for vehicles with z88/w49/wda. Tighten the boot clamp using the j 35910 - pliers by ensuring the gap between the boot clamp is 1.8 mm (0.07 in) for vehicles with x88 and 2.6 mm (0.10 in) for vehicles with z88/w49/wda. For cars with the earless kind of clamp ensure to close the boot clamp using ch 48894 -pliers while the ear type clamp be closed as us ed j 35910 -pliers, torque or ratchet wrench as well as breaker bar to close the boot clamp in a 1.9 mm (0,07 in)spaces for cars with x88. Inject the lubricant into the cv joint outer cavity by rotating the body of the cv joint at 90 degrees of angles at least four or five times then extract the wheel drive shaft and mount the wheel drive shaft assembly.

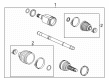

- Q: How to replace the inner CV Boot and CV Joint on Buick Regal?A:Start by collecting these tools to replace the wheel drive shaft inner joint and boot: tool use includes snap ring pliers (J 8059) swage tool (J 41048) and seal clamp tool (J 35910). Snap ring pliers (J 8059), swage tool (J 41048), and seal clamp tool (J 35910). Use a hand grinder to disconnect the swage ring from the halfshaft bar while safeguarding the halfshaft bar's integrity. Cut the large boot retaining clamp with side cutters and pull the inboard boot off the trilobal tripot bushing before sliding it away from the joint. Use snap ring pliers (J 8059) to break the stock-ring free from its position between the halfshaft bar and housing. Place the spacer ring along with the tripot joint spider onto the halfshaft bar before removing the halfshaft bar retaining ring . Thorough cleaning procedures should include both the tripot joint spider assembly and housing to eliminate every trace of old grease and all contaminants. Examine the inboard boot and the tripot joint spider assembly and housing and trilobal tripot bushing for signs of damage or wear. When assembling replace the inboard boot with the new swage ring securely fastened to its neck followed by boot insertion on the halfshaft bar then proper positioning in the boot groove . Use swage tool j 41048 to properly align the swaged ring on the inboard boot while ensuring there are no pinch points on this boot. Position the spacer ring onto the halfshaft bar before advancing the tripot joint spider assembly towards its position. Snap ring pliers (J 8059) are used to place halfshaft bar retaining ring into the fitting of the halfshaft bar. Add grease to the housing before installing the trilobal tripot bushing at a level with the housing and clip the bigger new clamp onto the inboard boot. Apply the housing onto the tripot joint spider assembly while checking that the inboard boot maintains its proper shape. The seal clamp tool (J 35910) crimps the inboard boot with the housing and large boot retaining clamp to 174 nm (130 lbs.) while confirming the clamp ear dimensions.