ChevyParts

My Garage

My Account

Cart

OEM 2004 Buick Rainier Pinion Bearing

Transmission Pinion Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Pinion Bearings found

2004 Buick Rainier Side Bearings Part Number: 25824250

$65.71 MSRP: $128.64You Save: $62.93 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing, Differential Side Gear; Differential Pinion Bearing; Differential Bearing

- Replaces: 09418390, 9418390

- Item Weight: 1.20 Pounds

- Item Dimensions: 4.3 x 4.3 x 2.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 25824250

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2004 Buick Rainier Pinion Bearings Part Number: 23243839

$56.88 MSRP: $110.40You Save: $53.52 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing, Differential Pinion; Differential Pinion Bearing; Rear Pinion Bearing; Front/Inner/Outer Pinion; Diff/Drive Axle; Pinion/Clutch/Rear Wheel

- Position: Front

- Replaces: 09418357, 26053758, 9418357, 15286375, 20997052, 22786621, 9418356, 09418356, 12479221

- Item Weight: 1.30 Pounds

- Item Dimensions: 4.2 x 4.2 x 2.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 23243839

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2004 Buick Rainier Side Bearings, Front Part Number: 26046759

$36.01 MSRP: $106.64You Save: $70.63 (67%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing, Front Differential; Bearing; Bearing, Differential Side Gear

- Position: Front

- Item Weight: 0.80 Pounds

- Item Dimensions: 3.0 x 3.0 x 1.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- Require Quantity: 2

- SKU: 26046759

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2004 Buick Rainier Pinion Bearings Part Number: 9439879

$35.47 MSRP: $105.01You Save: $69.54 (67%)Product Specifications- Other Name: Bearingfrt Differential Drive Pinion Gear Inner; Differential Pinion Bearing; Axle Bearing; Output Shaft Bearing; Rear Pinion Bearing; Inner & Outer Pinion Bearings; Differential Drive Pinion Assembly.

- Position: Front Inner

- Item Weight: 1.30 Pounds

- Item Dimensions: 3.2 x 3.1 x 1.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 9439879

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2004 Buick Rainier Pinion Bearings Part Number: 9417784

$24.86 MSRP: $68.16You Save: $43.30 (64%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pinion Gear Front; Differential Pinion Bearing; Axle Bearing; Rear Pinion Bearing; Front Pinion Bearing; Outer Pinion Bearing; Differential Drive Pinion Bearing; Front Axle Bearing.

- Position: Outer

- Item Weight: 1.10 Pounds

- Item Dimensions: 3.0 x 3.0 x 1.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 9417784

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2004 Buick Rainier Pinion Bearing

With a comprehensive array of OEM 2004 Buick Rainier Pinion Bearing, from fuel pumps to door handles, our website is a one-stop-shop for your needs. All our genuine 2004 Buick Rainier Pinion Bearing are backed by the manufacturer's warranty and are offered at competitive prices in the market. Rest assured, you can shop with complete confidence.

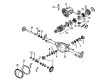

2004 Buick Rainier Pinion Bearing Parts and Q&A

- Q: How to replace the drive pinion bearings on 2004 Buick Rainier?A: The replacement of drive pinion bearings starts with vehicle lifting followed by Differential and drive pinion extraction from the axle. You should use split-plate bearing puller (J 22912-01) to unpack the bearing from the pinion before you delete the shim. A hammer and brass drift should extract the outer Pinion Bearing cup from the axle housing in an even fashion before removing the inner Pinion Bearing cup. The Pinion Bearing installation requires the outer bearing race installer (J 7817) for 8.0 inch axles while the rear Pinion Bearing race installer (J 8611-01) works with 8.6 inch axles and both tools must be used with the universal driver handle (J 8092). Apply the rear Pinion Bearing race installer (J 8608) together with universal driver handle (J 8092) to install the inner bearing cup in place. The operator needs to select the needed shim thickness which they will position between the inner Pinion Bearing and gear shoulder. Use the pinion cone and side bearing installer (J 24433) with proper technique to install the inner Pinion Bearing by pressing it until the cone seats on the pinion shim. Use a new collapsible spacer followed by application of appropriate axle lubricant to the pinion bearings. After axial positioning of the pinion slot inside the housing you must place the outer Pinion Bearing on it. The 8.0 inch pinion oil seal installation requires use of the pinion oil seal installer (J 33782) while the 8.6 inch installation demands the extension housing oil pump/seal installer (J 38694). Once the new seal is in position, apply gm p/n 12346004 (Canadian P/N 10953480) as sealant to the pinion yoke splines. Guide the removal marks while pressing the pinion yoke onto its pinion shaft with a soft-faced hammer until several threads become visible through the yoke. Screw the washer onto the newly installed pinion nut followed by the flange and pulley holding tool (J 8614-01) fastened to the pinion yoke. The technician should tighten the pinion nut with the holding tool in position before rotating the pinion while it sits against the bearing for complete seating. An inch-pound torque wrench should measure the rotating torque at 1.0 - 2.8 nm (10 - 25 inch lbs.) for used bearings while new bearings require 1.7 - 3.4 nm (15 - 30 inch lbs.) torque measurement. The technician must perform additional small nut rotations until the torque measurement reaches its intended specifications. When the specific torque value is reached you should turn the pinion multiple times to verify proper bearing seating before another torque measurement and potential adjustment. Reinstall the Differential followed by brake rotors, brake calipers, tire and wheel assemblies before filling the axle with the correct lubricant when lowering the vehicle.