ChevyParts

My Garage

My Account

Cart

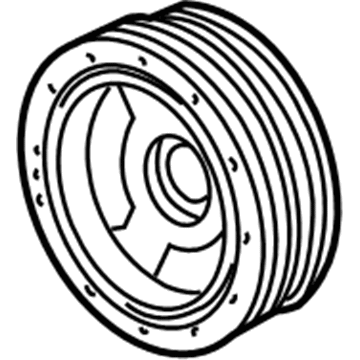

OEM GMC Yukon XL 1500 Harmonic Balancer

Engine Harmonic Balancer- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Harmonic Balancer found

GMC Yukon XL 1500 Vibration Damper Part Number: 12634105

GMC Yukon XL 1500 Harmonic Balancer

Want to cut long-term maintenance and repair costs? Choose OEM Harmonic Balancer. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine GMC Yukon XL 1500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM GMC Yukon XL 1500 Harmonic Balancer includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

GMC Yukon XL 1500 Harmonic Balancer Parts and Q&A

- Q: How to replace the harmonic balancer on GMC Yukon XL 1500?A:The necessary tools for crankshaft balancer replacement include the crankshaft balancer remover (J 41816) and crankshaft end protector (J 41816-2) alongside the Flywheel holding tool (J 42386-A), crankshaft balancer and sprocket installer (J 41665), and torque angle meter (J 36660-A). The procedure starts with removing the air conditioning Drive Belt for equipped vehicles but switching to removal of the accessory Drive Belt without air conditioning. After removing the lower Fan Shroud along with the Starter motor you must verify that the teeth of the Flywheel holding tool (J 42386-A) create proper mesh contact with the engine Flywheel. Apply the Flywheel holding tool (J 42386-A) with both m10-1.5 x 120 mm and m10-1.5 x 45 mm bolts before tightening them to 50 nm (37 ft. Lbs.). The crankshaft balancer bolt will be used again as a part of the installation process. Use the crankshaft balancer remover (J 41816) and crankshaft end protector (J 41816-2) for removing the crankshaft balancer while subsequently cleaning and performing an inspection. The installation process begins by positioning the crankshaft balancer directly on the crankshaft which can be facilitated by using the crankshaft balancer and sprocket installer (J 41665). Use the threaded rod along with nut and washer together with the installer to push the balancer front end before tightening to start the crankshaft installation. After reversing the installation tool start tightening the tool until the balancer reaches its complete installation position. Screw the previously used crankshaft balancer bolt into position before torquing it to 240 ft. Lbs. (330 Nm). Remove the bolt afterward. The measurement of correct balancer installation needs to be repeated for the crankshaft balancer and sprocket installer (J 41665) when the results show improper installation. Position the new crankshaft balancer bolt and tightly install it first at 50 nm (37 ft. Lbs.) and complete the installation at 140 degrees using the torque angle meter (J 36660-A). Perform the crankshaft position system variation learn procedure after reinstalling the Starter motor and lower Fan Shroud followed by accessory drive and a/c drive belts and removal of the Flywheel holding tool (J 42386-A) and bolts.