ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Suburban 1500 Engine Mount

Engine Motor Mount- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Engine Mounts found

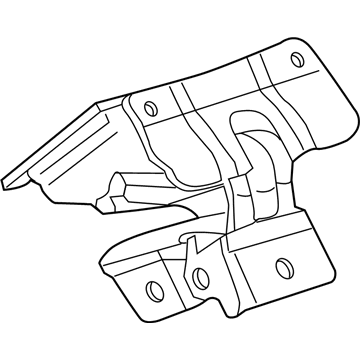

Chevrolet Suburban 1500 Motor Mount Part Number: 15226255

$125.59 MSRP: $215.69You Save: $90.10 (42%)

Chevrolet Suburban 1500 Motor Mount, Green Part Number: 25828247

$132.41 MSRP: $227.41You Save: $95.00 (42%)

Chevrolet Suburban 1500 Motor Mount Part Number: 15854941

$148.55 MSRP: $252.92You Save: $104.37 (42%)

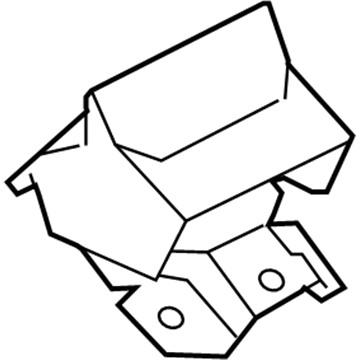

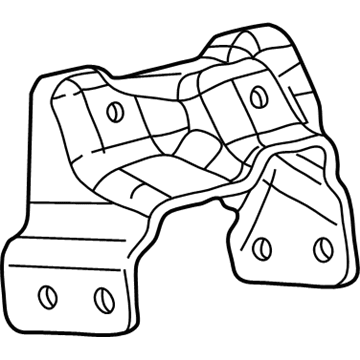

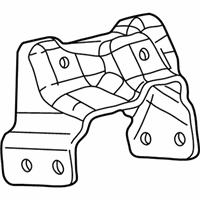

Chevrolet Suburban 1500 Mount Bracket, Passenger Side Part Number: 15113847

$47.39 MSRP: $80.69You Save: $33.30 (42%)Ships in 1-2 Business DaysChevrolet Suburban 1500 Mount Bracket, Driver Side Part Number: 15113849

$59.70 MSRP: $93.50You Save: $33.80 (37%)

Chevrolet Suburban 1500 Engine Mount

Want to cut long-term maintenance and repair costs? Choose OEM Engine Mount. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Suburban 1500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Suburban 1500 Engine Mount includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Suburban 1500 Engine Mount Parts and Q&A

- Q: How should you inspect and maintain the engine mount to prevent misalignment and damage to drive train components on Chevrolet Suburban 1500?A:Any issues with the Engine Mount that lead to misalignment and drive train component damage should be inspected because remaining mounts will experience extra stress when a failure occurs. Place a screw jack underneath the engine to support its weight but never position it under any components that include the Oil Pan sheet metal or Crankshaft Pulley since bending of the Oil Pan against the oil pump screen will lead to damage of the oil pickup unit. First lift the engine to empty the mount weight then apply minimal tension to the rubber cushion while watching the mount components. The mount requires replacement if heat check cracks appear on the hard rubber surface or if the rubber cushion gets separated from the metal plate or if the rubber material has a split running through it. The engine should be lowered for proper maintenance so the bolts or nuts can be tightened at the engine frame or bracket. A transmission extension housing test should be executed through upward and downward motions which requires a replacement of the mounting when any of these conditions arise: rubber separator movement from the metal plate, complete mount extension or inability to push the housing downward. The tightening of loose bolts or nuts has to follow fastener tightening specifications (specifications).

- Q: How to replace the left engine mount on Chevrolet Suburban 1500?A:The first step in replacing the left Engine Mount includes removing both Engine Mount-to-Engine Mount bracket bolts (the right side appears in this illustration but the left side follows the same process). Support the vehicle securely and remove its engine shield bolts followed by removing the engine shield with caution when avoiding contact with crankshaft balancer or Oil Pan. Screw-type adjustable jack stands will support the engine while you remove the Engine Mount bolts and left Engine Mount from its position. After placing the left Engine Mount onto the engine position you should start installing its Engine Mount bolts before finalizing them to 50 nm (37 ft. Lbs.). Replace the adjustable jack stands and lower the engine before you secure the engine shield to the vehicle with engine shield bolts which need to be tightened to 20 nm (15 ft. Lbs.). The right side Engine Mount-to-Engine Mount bracket bolts need to be installed finally with a torque setting of 65 nm (48 ft. Lbs.) while the left side requires the same torque.