ChevyParts

My Garage

My Account

Cart

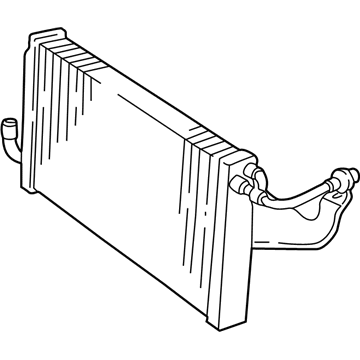

OEM Chevrolet Astro A/C Condenser

Air Conditioning Condenser- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 A/C Condensers found

Chevrolet Astro Condenser Part Number: 89019058

Chevrolet Astro Condenser Part Number: 52461196

Chevrolet Astro Condenser Part Number: 52456513

Chevrolet Astro Condenser Part Number: 3055040

Chevrolet Astro A/C Condenser

Want to cut long-term maintenance and repair costs? Choose OEM A/C Condenser. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Astro parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Astro A/C Condenser includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Astro A/C Condenser Parts and Q&A

- Q: How to replace the A/C Condenser on Chevrolet Astro?A:The replacement process starts with getting the needed equipment that consists of the halogen leak detector (J 39400-A). Start by taking out the air cleaner assembly before recovering refrigerant from the system. Begin the process by removing the grille before soaking the compressor hose assembly nut at the condenser then proceed with compressor hose assembly removal. You need to loosen the evaporator tube nut at the condenser before removing the evaporator tube. Remove first the center support bracket and bolted condenser to Radiator connections before extracting the condenser unit and discarding o-ring seals. Add pag oil to your new condenser before putting it back onto the Radiator then bolt it down to 6 n.m torque (53 lb in). Begin by installing a new center support bracket followed by correct installation of o-ring seals. Secure the evaporator tube to the condenser by tightening the nut with torque of 28 n.m (21 lb ft). Assembly the compressor hose using fresh o-ring seals before torquing its nut to 28 n.m (21 lb ft). The process concludes with air cleaner assembly installation after system leak testing with the horagen leak detector (J 39400-A), system evacuation, and recharging.