ChevyParts

My Garage

My Account

Cart

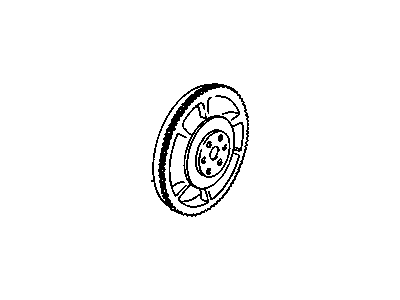

OEM Cadillac DeVille Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Flywheels found

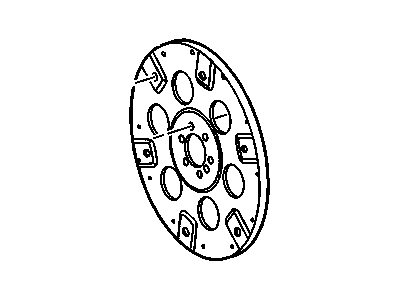

Cadillac DeVille Drive Plate Part Number: 3544671

$97.14 MSRP: $136.33You Save: $39.19 (29%)Ships in 1-2 Business DaysCadillac DeVille Drive Plate Part Number: 3521829

Cadillac DeVille Drive Plate Part Number: 22520094

Cadillac DeVille Drive Plate Part Number: 22500808

Cadillac DeVille Drive Plate Part Number: 1648458

Cadillac DeVille Drive Plate Part Number: 1623936

Cadillac DeVille Drive Plate Part Number: 12568988

Cadillac DeVille Flywheel

Want to cut long-term maintenance and repair costs? Choose OEM Flywheel. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Cadillac DeVille parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Cadillac DeVille Flywheel includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Cadillac DeVille Flywheel Parts and Q&A

- Q: How to replace the engine flywheel on Cadillac DeVille?A:The first step when replacing an engine Flywheel demands transaxle assembly removal. The next step involves placing the Flywheel holder (J 44214) onto the engine block then opening the eight engine Flywheel mounting bolts. Only fasten the top mounting bolt of the Crankshaft while loosening all other seven Flywheel bolts. Slowly pull on the engine Flywheel while removing the last bolt while avoiding any Flywheel drops. Before adding gm p/n 12346004 (Canadian P/N 10953480) or equivalent sealant to the Flywheel mounting bolts the inspection and cleaning of the engine Flywheel should be done. Install the Crankshaft accordingly while positioning the engine Flywheel into place before fastening all the mounting bolts. The first tightening stage of Flywheel mounting bolts should be 15 nm (11 ft. Lbs.). When using the angle meter (J 45059) for the final bolt tightening step follow the gauge to achieve a 50-degree torquespread distribution. Wrap up the task by taking off the Flywheel holder (J 44214) from the engine block then reinstalling the transaxle assembly.

- Q: How to service and repair the Flywheel on Cadillac DeVille?A:Cleaning the engine Flywheel starts by immersing it in solvent solution underneath protective safety glasses until the engine Flywheel reaches full dryness. Use compressed air to dry the cleaned Flywheel of the engine. You need to examine the engine Flywheel for stress cracks at the areas defined by engine Flywheel-to-Torque Converter mounting bolt hole locations and engine Flywheel-to-Crankshaft (2, 4). Tests and fixes of the weld points connecting the ring gear to the engine Flywheel plate must be avoided completely; users need to replace the engine Flywheel with a new one. An inspection should be performed for both cracked welded areas retaining the ring gear to the engine Flywheel plate along with an evaluation of ring gear tooth condition. It is necessary to replace the engine Flywheel in case of failure.