ChevyParts

My Garage

My Account

Cart

OEM Buick Terraza CV Joint

CV Joint Axle- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 CV Joint found

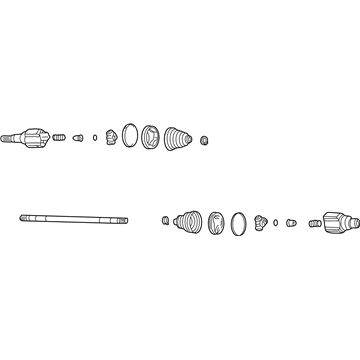

Buick Terraza Axle Assembly Part Number: 88967242

Buick Terraza CV Joint

Want to cut long-term maintenance and repair costs? Choose OEM CV Joint. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Buick Terraza parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Buick Terraza CV Joint includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

A Buick Terraza CV Joint stands as an essential element which significantly enhances both performance and reliability of the Buick Terraza luxury minivan built with practical design features. This CV Joint efficiently moves the transmission power to drive wheels while maintaining smooth continuous velocity for all front-wheel-drive and all-wheel-drive setups. Multiple Buick Terraza models from 2005 to 2007 benefit from the joint because owners seeking to keep their vehicles' performance levels need this universal design. Two CV joints known as Rzeppa and tripod serve the Buick Terraza CV Joint to support diverse operating angles that help make the car more efficient and safer to drive. The combinations of flexible rubber boots with lubricant inside serve to protect the joints by stopping contaminants and preventing premature failure so routine inspections remain essential. The Buick Terraza combines its elegant chrome appearance with a distinctive front design to deliver better crash ratings and further demonstrates how the CV Joint enhances vehicle safety. Its exceptional styling with comfort and leading safety capabilities make the the automaker model with its reliable CV Joint position dominantly in automotive markets to deliver pleasant driving to various consumer profiles.

Buick Terraza CV Joint Parts and Q&A

- Q: How to Service and Repair the CV Joint Boot on Buick Terraza?A:To service and repair the constant velocity joint boot, first, collect the necessary tools: snap ring pliers (J 8059) and drive axle seal clamp plier (J 35910). Remove the very large seal retaining clamp from the cv joints using a side cutter and throw it away while being careful not to cut through the wheel drive shaft inboard seal to avoid causing a damage. Sever the swage ring at the halfshaft end with a hand grinder and split the halfshaft outboard seal from the CV Joint outer race at the greater diameter and slide the seal from the joint along the bar of the halfshaft. Clean the grease from the CV Joint inner race and position the ears on the ring for the race retaining ring widened with the snap ring pliers (J 8059). Remove the CV Joint assembly from the halfshaft bar and discard old outboard seal. Leveraging on a brass drift, you will tap and tilt the CV Joint cage carefully in order to take out the chrome alloy balls, doing the repeat until the six of them are completely taken out. Clean the inner and outer race assemblies, CV Joint cage also the chrome alloy balls smartly with a cleaning solvent followed by drying all the aspects and inspect for unusual wear or crack or damage and make sure to change any dented parts. Using a wire brush, clean the halfshaft bar getting rid of rust in the seal installation area. For installation - mount the halfshaft in vice with the towel to protect, then install the new small eared clamp on neck of the outboard seal do not crimp. Slide on the outboard seal onto the halfshaft bar by ensuring it is oriented in the seal groove. Crimp the eared clamp using the drive axle seal clamp pliers (J 35910), breaker bar, and torque wrench to 136-n.m (100-lb ft) and watch the gap dimension as you tighten. Apply a light coat of grease from service kit on the ball grooves of the inner and outer races then put the inner race in the cage aligning it properly. Put the cage and inner race in the outer race, then fill the cars by putting the chrome balls sequentially till all are in place. Pack the CV Joint with grease, making sure that the outboard seal is not dimpled or stretched and push the CV Joint onto the halfshaft bar so as to ensure that the retaining ring is seated. Push the large diameter of the outboard seal with the large seal retaining clamp positioned, crimp to 176 n.m (130 lb ft) and checked the gap dimension at the clamp postured.